-

Posts

219 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Granite Falls, (near Everett,WA)

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Stories behind smithy/forge names...

4elements replied to elkdoc's topic in Blacksmithing, General Discussion

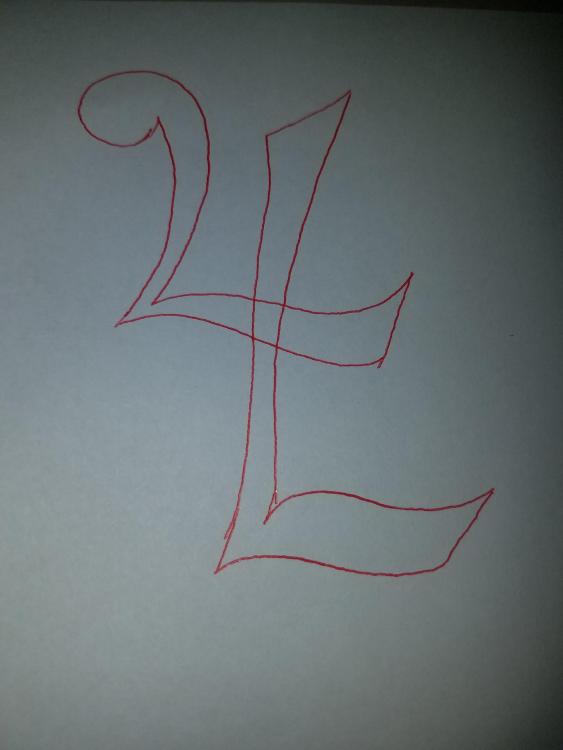

Anvil, my choice of name was informal since I'm a hobbyist, not a business but I could put a little more distinction into it. "Four Elements Forge" would be just as suitable for me. I didn't do any more than a quick internet search on the name which didn't return any blacksmith related results. This is my logo design -

Stories behind smithy/forge names...

4elements replied to elkdoc's topic in Blacksmithing, General Discussion

The first book I ever read on blacksmithing was Alex Bealer's The Art of Blacksmithing in which he mentions the four elements of the ancient Greeks, and since the name didn't seem to be taken already I'm using 4 Elements Blacksmithing for my hobby smithy. -

Please remember to stay hydrated. The heat can sneak up on you when you're having fun and it's definitely compounded by a forge.

-

Hi Timothy, what type of shop is it in? I see heavy truck leaf springs, possibly from a dump truck. The stand appears to be shop made. More info might help with the answers you get.

-

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

Hi Jennifer. I really like those videos from you that i've watched. I consider them some of the best. I do have to watch them more than once to get it all down. I'm too slow to read and watch two views at one time. That is a result of information density and a positive feature. -

My son drives a dump truck and the company replaces the entire spring set when one leaf breaks. I had to tell him not to bring me any more because I have several hundred pounds already. Some leaves even have a straight section in the middle. You might ask at a truck company or truck repair shop.

-

Dressing my anvil stand (read stump)

4elements replied to Eventlessbox's topic in Stands for Anvils, Swage Blocks, etc

If the stump will be set directly on the ground consider applying wood preservative to the end and soak it into the end grain -

Find a copy of "Celtic Art, Methods of Construction" by George Bain. It deals with the patterns, not the materials, but is a good starting point.

-

Look at the NWBA web site, blacksmith.org for details. There will be a tailgating section, demos, an auction and lots of good comraderie. I hope to see you there.

-

Thanks Slag, that may be even better

-

Thanks for the idea. That might get me his name but at this length of time (about 46yrs) who knows what could have transpired? I know my own life has had plenty of twists and turns. It was from him that I first heard of ABANA, but I don't know if he was a member. I've never joined so I'm putting it out to the broadest group I can (I know international is VERY broad) because I don't remember enough specifics, such as addresses, shop name, other people, etc.

-

When I was an 18YO kid I went to school briefly in Kansas city. I there I first met a working blacksmith. He had a shop in an area called The River Quay, a craft and art district. He shared space with a silversmith and a glass blower in the basement. I long ago forgot his name, but that short acquaintance left me with a lingering desire which I didn't see realized until I was in my 50s. Now i remember that time and inspiring Smith and i wonder if anyone knows who he is/ was, and if he's still around?

-

When I started I had no assurance of success but I went ahead anyway. Risk is part of learning. When I got them shaped, they were still flat. I then had to bend and twist them. With them so thin at that point it didn't take much to heat, but they also didn't hold that heat long. I had to keep careful watch so I didn't work too cold and break them.

-

I refined them with a dremel tool using a reinforced abrasive cutoff disk, and yes patience.

-

This is my very first attempt at an animal head. I need to work on the head proportion on the next one. This was just practice to see what I could do. I like how the antlers worked out.