-

Posts

5,782 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

What was the job that you turned down?

jlpservicesinc replied to Glenn's topic in Blacksmithing, General Discussion

It only takes one.. My award winning personality is the big seller. -

Pictures are always a welcome site.. Lots easier to see.. I'm not Lucky, but your gonna need more than 3/4" of blast to do any kind of work.. A wood forge has to be stacked deep.. If you have enough 3/4" holes it would work.. figure out the area with the opening that is there in the firepot.. it's probably 3" round or 2.5" round Guessing.. That forge was made by Buffalo forge of Canada.. That was there brand name up there.. You guys actually got a few items that weren't available in the states.. Kind of neat..

-

What was the job that you turned down?

jlpservicesinc replied to Glenn's topic in Blacksmithing, General Discussion

The more you charge.. the more you are worth..??????????? At least that is how one class of citizenship sees it.. Strange world where the quality of work does not equate.... -

I have an 8".. It is a wonderful vise.. I paid a pretty penny for mine but happy I did.. 203lbs is what the 8" weighs.. It's a beast to move around.. Congrats on finding yours.. Larger sizes are harder to come by and certainly more expensive so if you paid under 200.00 it was a bargain.. go back and get the mount..

-

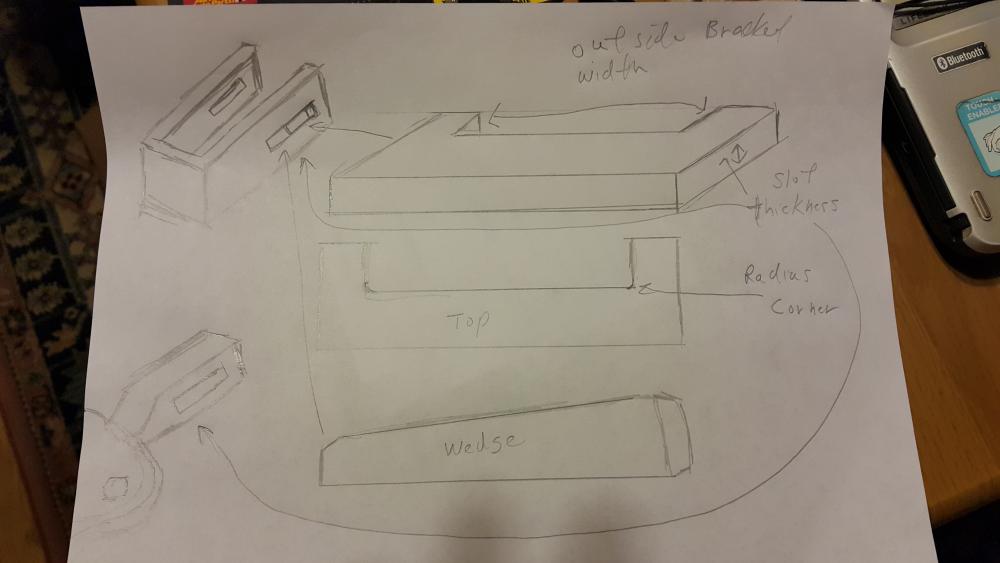

Here you go.. The ears go towards the mounting bracket and the wedge goes closest to the vise. Make sure your ears are plenty strong.. Especially on an 8" vise.. Nice find and good price.. Would like to see more pictures.. Maybe some detail shots of the screw, jaws, etc, etc.. looks like you need a new bolt? Is the bolt hole tapered?

-

Well Said Robert..

-

I knew a guy who forged in a teepee back in the 80's and 90's.. The winters got to much for him so he moved into a regular shop. he made his own clothes, shoes, hats.. He was an excellent knife maker including swords and such as well.. Charlie Lappen Brilliant guy.. He also used Anthracite coal to forge with.. His forge looked like a small wheelbarrow lined with cement and salt.. Made some really nice stuff.. He used a 5" bench grinder for finishing all his blades.. Really just amazing..

-

only if over tightened.. Only if it's jammed in very hard.. I have machines and lathes with Morse taperes.. I know how they work.. and only if badly fitted to begin with.. A taper has the adjustment all ready built in vs having to figure it out.. If you are an engineering type and it's all about the numbers than fitting by feel may not be your thing.. I know someone that unless you can read it to 0.00001 it's not accurate.. That great for him.. I am happy to 1/32nd of an inch.. Like I have all ready mentioned forging a bolt to shape is not a big deal even when working to tight tolerances.. I think you are overly concerned with what or what doesn't the bolt do.. It works together as a whole unit.. Even if you use a straight bolt like many of this vises did.. It's the taper in the bosses that distributes the pressure across many sq" vs just on the bolt.. Not a problem.. Have you had the vise apart yet? Check all parts for known wear.. Don't make assumptions as to what is worn or not.. If the front jaw is higher the back jaw might be bent.. This can be corrected by first filing or burring the high side till it just about sits where it belongs then ream it then put a morse taper ream through it or pick a ream with the degree you want.. Or just drill it straight if it has a straight bolt all ready.. If the cheeks are not making contact with the reciever grooves, check the distance and then measure the difference in jaw height.. someone might of drilled the hole all ready and did a terrible job making the jaws out of plane as well as the contact surface of the cheeks..

-

Okay, so the stress is the same if you want to get into equations. The force applied is the force applied and can be exponetially equated to difference loads, thicknesses.. etc, etc.. . What is not the same is the area in contact.. a tapered bolt offers more contact than a straight bolt.. Also for it to bind there would have to be no lubricant and forced in dramatically.. LOL.. fun right.. If you have to shim your vise.. The question becomes why? And how much of a shim in area are you actually putting in contact with the vise arm that is helping to eliminate the play you are associating with torquing when threading a bolt? is it a big shim in area so offering more area to the vise jaw arm? The arm only has so much width or thickness.. Or is it a shim 13mm wide at each side of the bolt? Is there that much play because the vises bolt, or cheeks are worn or because it's rusted and the material is gone.. Each one of these pays into the next.. on any of the vises I have shown you. You wouldn't be able to fit even a 0.0001 shim into the joint unless there was something drastically wrong..Like a bent bolt or a completely egged out pivot hole, or a front jaw being bent downwards from abuse and then you would still need a egged out pivot hole.. Post some pictures of the vises worn surfaces and lets see exactly what the problem is.

-

You are saying the basic same information.. Only one clarification.. The tapered bolt only holds the the jaws in alignment by keeping pressure of the bottom boss/pivot in contact with the cheek when there is no load and the jaws are nearly shut.. the bolt only holds the jaws straight while in the nearly closed position to about 1.5 -2" out..(nothing said about a load or force) After that it's the taper of the cheek plates that holds the jaws straight.. If you want to talk about loads take a vise as in the pictures and it will make sense.. Tighten the nut as you move the jaws you will see the results.. Rust has nothing to do with it.. I high lighted your example above.. You are also talking about Torquing forces verses hammer forces or linear forces.. 2 total different forces and this I was not referring to at all nor mentioned.. A blacksmith leg vise will always have twist in it if you are threading a round rod.. it is deforming to offset the forces you are putting into it, It's not really designed for the greatest jaw stiffness in a torsional use environment.. It's designed to be pounded on and the reason all the pieces are designed the way they are.. Those same torsion forces come into play when holding anything off center of the jaws..in a small vise you can see the amount of torque being applied as the off side jaw moveds towards the stable jaw very easily.. Larger vises have less deviation because of the larger mass.. a Torsion rod in a car twists to create a load at either end of it's attachment points an this is supposed to help recenter the car body mass.. so it bends then once the car is level again.. so is the rod.. A leg vise has very long members in relation to jaw and then screw distances and then pivot.. that 2FT of torsion rod.. You will get twisting in the front jaw no matter what you do.. it's like a torsion rod in a cars suspension.. You can tighten the joint all you want and it will still torque.. It's how it's designed.. The only way you can get little or no torque movement is a very short jaw profile with very short pivot like in a machinist vise.. Your looking at this from a very different perspective.. What you see is a different picture of what I'm showing because of perspective.. I'm showing how the vise jaws stay in alignment with forces being applied in hammering which are downward or backwards (towards the rear jaw) for the most part.. What I took away is : You are looking at twisting motion.. Ain't no way you are going to get them to stay straight to much torque load out at the very end of a long member.. You'd have to redesign the whole thing if you want to overcome torque loads.. Buy a very high quality machinist vise and you will be all set... . Apples, oranges.. Pineapples.. No wonder why it doesn't make any sense.. Your looking at how to stabilize the jaws against torque instead of straight downward force.. So, because you are looking at this all torquey.. It is the exact opposite.. because the bottom boss and the cheeks are a taper.. As you twist the rod in the jaws the vise front jaw will want to torque as its' not only over coming your twisting forces but also now you have a wedged cam going on at the bottom. . Basically your are wedging the jaw at the boss and this will actually cause a loosening of the area and the bolt will have little effect other than holding the cheeks together and keeping the jaw from rising.. In this situation a straight sided wall would be best, (not wedging) but then you would end up with all the load when hamming on the vise going into the bolt unless you had a german vise where this load is shed partially by the cheeks and the guides bosses on the jaw... Just put a wood wedge in a vise and tighten it slowly.. the wedge will raise.. or put it in a vise and just twist it with your hand.. it will raise as well... or a cold hardie. Even a better example.. If the twisting of the jaws is really what your looking at eliminating they a high quality machinist vise will solve your problem.. Most old time shops had a leg vise and a machinist vise for the exact reason you are talking about... Even the big 8" Columbian vise which weighs 230lbs and the moving jaws leg 2.5"X 1.5" twists when I'm threading 3/4" rods. If a free world, with free thought.. You can do all you want to.. I'm merely showing how these things were made.. If shimming works for you.. Go for it. Personally I go and fix what is wrong and then I also account for the limitations of the equipment I am using and adjust to get the desired results.. I tap and thread rods in the foot vise all the time and find the twisting of little consequence other than having to realize there are other counter forces at play.. If it's the tapered bolt, don't use one.. there is a reason this stuff works.. I'm not the designer or the engineer.. I'm just a user who shared what they know.. In the end you can do what ever you would like.. It's all good.. Right or wrong makes no difference as it's all perspectives which change with time...

-

That's awesome.. nice find.. How much?

-

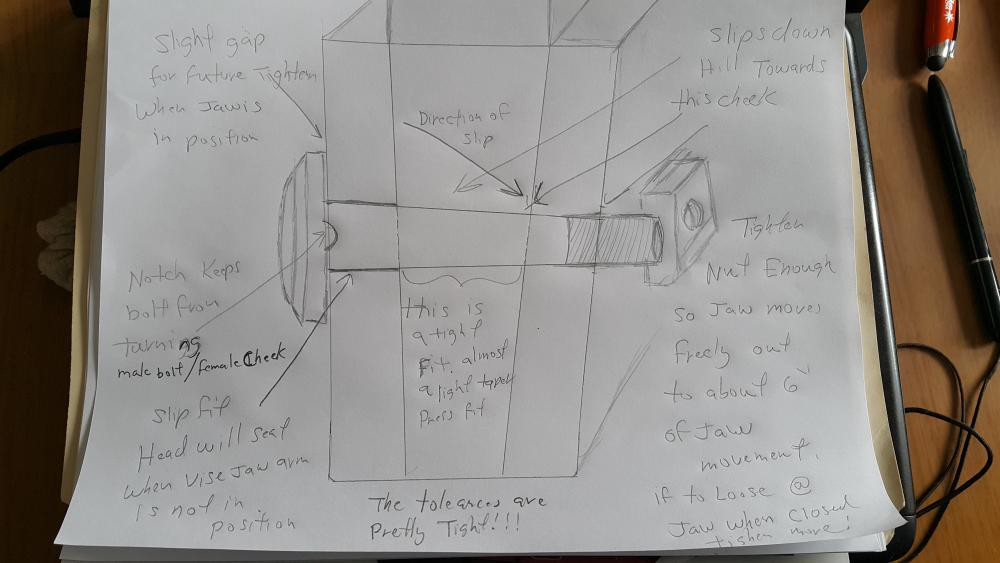

Look at the picture again.. The notch in the bolt head and the same cutout in the cheek keeps the bolt from turning.. Look at the pictures I posted earlier.of the newly made bolt. It shows these notches clearly.. I think in some way you guys over think this stuff.. The drawing it shows that the bolt to the vise jaw is "almost" a tapered press fit.. I didn't say it "IS" a tapered press fit (and pull the bolt in till it binds) that would bind like a "Morse taper" by the way a morse taper "Will Not Hold" very well or bind (which is how it really works) if there is ample oil, dirt or grease in the socket with no inward pressure.. Remember for a morse taper to hold properly it has to be clean or lightly oiled and then "Forced in" till the two sides (faces of the female and male socket) have pressure evenly placed (IE Jammed together).. This pressure inside the so called "almost tapered press fit" is controlled by how tight the nut is on the outside and hopefully you grease or at least oil the joints upon assembly. The bolt is not to support the jaw, the cheeks are to support the jaws,, The bolt is to add cheek pressure and it keep them from spreading as well as acting as the pivot for the jaw and keeping it located in the cheeks (pivot). It is a combination of all things.. Tapered cheeks, tapered jaw boss, tapered bolt.. . This makes the vise nearly indestructible and why they last so long.. without the tapered cheeks the bolt becomes the main weight bearing. It will fail in short order as the bolt is in a shear plane all the time.. (They did make the cheaper ones that way). German vises use the cheek plates as part of the weight bearing and supporting structure but in a somewhat different manner.. If your cheek plates are damaged or the receiver bosses in the jaw for the cheek plates are damaged.. Then the first culprit to make it straight will be the bolt most likely deformed.. means there is deformation at the bolt, the vise jaw boss and the cheeks or a combination of all 3.. The only fix for this is to make everything like it was brand new with the proper clearances.. Adding shims is not how this is fixed.. Fixing it the right way with adding materials (IE welding) or putting back the materials (peening back) that have been distorted, checking to make sure the bolt is not deformed, making sure the clearance in the vise boss is not egged out.. ETC, ETC.. For clearance you can make what every you want or find what works.. Your going to make the thing right... Just forge it out and then see what works.. (In regards to your question about bolt clearance under the head) for the clearance around the side cheek with the bolt head on it.. The shaft under the head can be the same taper as the rest of it with no clearance at all.. Problem is if you tell someone this who has never made one they make the head exactly at the cheek and this eliminates the ability for further adjustment in the future. and will actually make it so the contact area between the bolt and the jaw boss will be to small (it will be Sloppy). Then they come back and say I don't know what I'm talking about.. Because it didn't work for them and they spent all the time when they could have just drilled the hole out and put a regular bolt in.. So after a new bolt is made.. make it exactly to the tapered fit.. Just leave some clearance under the head.. Is that more helpful.. then I say figure it out on your own. The information is there. "It's correct for this type of vise pivot".. I've seen hundreds of examples and this design is the most robust.. I've also seen straight jaw bosses, straight bolts. I've seen lots with stripped threads because the jaws didn't align and the person just over tightened the bolt and as soon at they open the jaws which are now very tight at the 0-1" mark can barely be opened the rest of the way and they force it and the threads sheared off the bolt so no nut.. Give it some more thought and though it may seem frustrating and that its not understandable when the "Ah Ha" moment comes it will be crystal clear.. Just because something is made by hand via a blacksmith does not mean it can not be accurate and made to an exact size.. By the way.. I'm not an artist blacksmith.. I'm a trades blacksmith.. So, the simplest answer is to just fix what you find to be wrong.. If your vise doesn't have a tapered bolt forget all about what I wrote.. It's that simple.. Oh one other thing.. Some of the vises don't have a hotch to hold the tapered bolt.. since the taper on both cheeks has great area vs the pivot it still gets held against the pressure of the pivot to turn the bolt..

-

Ok, so just to clarify: It's the vise cheeks and taper that keep the jaws in alignment when under pressure.. The bolt limits the spreading and this keeps the outside jaw from sinking lower when impact is made. This downward force acts like gravity and pushes the bottom jaw boss more sideways then down... The thru bolt is not receiving all the pressure.. This side load transfers some of the forces to the cheek.. Since the cheek plates and the boss on the jaw are tapered as the jaws open it wedges the jaws deeper at the front of the wedge.. This keeps the jaws in alignment as the jaws open past a certain point.. The play is more than likely caused by either a worn bolt or a loose nut and worn bolt.. The cheek plates will flex some when tightened.. Think of a hill and a ball.. The ball will always roll down hill.. The tapered pin is the hill and the ball is the vise bottom boss.. The taper serves 2 functions: increases the contact area between the jaw lower boss (pivot) and the bolt vs a straight bolt and helps to shed the load sideways into the cheek when struck.. It also helps with shear loads since the sideway forces involved redirects the load.. I've attached a crude drawing but it should help explain some of it.. Them old workmen who made all this stuff really had it figured out.. More knowledge has been lost than has been gained in my mind. Also while a lot of this information applies to blacksmithing foot vises as a whole there are variations for any given maker and/or where it was made.. German made vises and the older italian made vises are beautiful and beautifully made.. American's simplified and expedited everything.. By the way all the new commercially available vises have done away with the tapered bolt and bottom cheeks.. Costs more to MFG..

-

In the years since I really looked into this stuff.30 years ago, I have forgotten more than I remember at this point.. Coal smoke is a heavy smoke.. It is heavier than air.. It will sink vs rise if given a chance.. So, pressure differential can be a friend,(have a tight shop and having a fan in the window blowing air in will pressurize the buldiing and make the stack draw better), and then a hot pipe. (we all know a hot fire draws a lot better). I paint the stacks black so in the summer sun they get a little hotter from the sun then the cooler air at the ground.. this helps with Draught/draft.. A proper stack/hood design is the next phase.. My recent trailer build I was asked why a tall stack.. The higher the stack up to a given length the more consistent the draw and the higher the velocity of the slower air which is not smoke and such as the air at the ground is cooler and as it's heated while going over the forge will pick up some heat and this will help the cycle continue.. Also a longer stack will handle pressure differential pulses better.. The secret to a smoke free shop is to design a stack/forge hood to catch the smoke before it has a chance to expand.. Cooler air being drawn into the heavier coal smoke will make it want to settle back on itself and starts to expand as it cools rapidly and separates out of the heat stream. The stack is about 15ft long.. 12"X12"..

-

the lever blowers were an early adaption away from bellows.. It still retained the pump, pump, pump like the bellows people were familiar with but had the blower.. some of the pump models worked very well even better than some of the lower billed hand crank blower models. Other nice thing is the pumping can be a lot easier on the shoulder if the lever is low enough..

-

Not clear on what you mean by " I do not really understand this. Of course a tapered pivot in tapered holes can be pushed in so that there is zero play but how do you do that if there is a head on the pivot?".... What head on a pivot???? The bolt does not center the jaw.. The pressure on the side forces of the taper force the jaw mount to one side.. This puts force onto one side of the cheek plate keeping the jaws in alignment at the the top.. Side pressure against only one cheek plate.. The bottom portion of the vise jaw boss has a taper the same as the cheek plates.. Narrower at the bottom than the top.. The bolt that goes through both cheek plates and the vise jaw leg boss has the same taper with a tapered hole.. The tapered pin (threaded bolt that goes through) takes up the cheek plates to keep them fairly tight and from spreading.. A tapered cheek vise will not open past a certain distance between the jaws because of the wedging effect of the cheek plates.. If you loosen the bolt it will open more because you are forcing the wedge into the cheek plates spreading them..

-

Wrought Iron Wheels/ rims

jlpservicesinc replied to BOB T's topic in Blacksmithing, General Discussion

Yes it is.. Lots of good information here on WI.. I regretfully gave away about a ton of it back when I quite smithing.. Was great quality.. Gave it to a blacksmith friend of mine who ended up with my 200lbs Myers.. If you have a chance to get the bridge.. It would be such a sweet deal.. Most that stuff goes to Scrap here without ever having a chance to grab any as the state projects frown on any civilian approaching a work site.. -

Wrought Iron Wheels/ rims

jlpservicesinc replied to BOB T's topic in Blacksmithing, General Discussion

BobT, This thread probably turned into a whole different beast than expected?.. Here are some pictures of the wrought iron I stumbled across while out walking.. As mentioned before I believe they were used for rigging for cranes that worked on the Railroad as well as a watershed project by the state.. One other thing about wrought iron.. Overall it's not as strong as mild steel.. Tensions it's only ok. compression is pretty good. But any notch test and it will usually fail.. I had to cut a 3/4" bar to be able to straighten a section and with only an 1/8" notch I could easily break it in 2.. I was going to show some little videos on the difference between forging hot short and cold short as I had a piece that hated being worked hot so much so I think the guys who made it were happy to see it leave the shop.. It was originally used for a loading dock bumper.. Anyhow, after I was done with the majority of trailer making I had a scrapper helping me clean things up and the section (about 2ft long) must have gone with him.. Oh, well.. anyhow heres some pictures of the iron i found and the notch I cut in with the open break.. -

Slooks good to me.. besides ghat if anybody gives you any guff that B.O. would make a formidable weapon..:) A friend of mine came over for knife making day I was 15 and he was 14.. We made knives out of what ever was hanging around.. He ended up picking a bar of some low-medium carbon 1030. about 20" long.. He forged a blade on the end of it about 6" long.. I said it will never work, or hold and edge (low carbon) and since he burnt it would break in use.. That knife he made was such and excellent chopper.. only about 1/8" thick at the spine. the blade held a great edge, it never cracked or bent.. I used to water harden everything. Anyhow, the only explanation I could come up with is " Him burning the metal gave it just the right brittleness so as to offer all the attributes the blade had.. Maybe a 1 in a million shot, whos to say..

-

Wrought Iron Wheels/ rims

jlpservicesinc replied to BOB T's topic in Blacksmithing, General Discussion

go over to where there are any old mills and just look around.. or old farm silo's.. Before the chinese bought up all the scrap a few years ago you could find it just about everywhere.. Now it's slim pickens but still find a piece here or there if you look.. go over to abandoned farms.. In the olden days people would just stack the scrap up.. Today on my way home from feet duty.. I stopped by an old mill site which burnt and grabbed a few ends just laying in the dirt.. There were some 1"round rods about 12ft long but they were stuck in pipe filled with clay in a brick foundation and the nuts were still on the ends.. Can't make off with those on the down low.. I did just find 4) 3/4" rounds 20ft long that were used on the rail road for stabilizing crane rigging.. These had the stamped in numbers of the smith who made them.. Pretty awesome.. The forge welds were perfect.. I'll post pictures up tomorrow.. Also found some vintage rebar.. They were all just stacked up like someone forgot about them.. I had to dig them out from under trees and roots and about 6-12" of new soil/hummus.. -

Farrier tools Hand forged, not factory.

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Yes old leaf springs.. the short one I made on my own and the long one I had a striker. Took like 15min with his help in the sledge. -

Farrier tools Hand forged, not factory.

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

huh. From the picture looked like horn to me.. -

Farrier tools Hand forged, not factory.

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

That is sweet.. Antelope handle? or deer -

What was the job that you turned down?

jlpservicesinc replied to Glenn's topic in Blacksmithing, General Discussion

Ah, are these blacksmithing jobs or any jobs? If I take out the time machine and go back 20years I'd say I'd do nothing different but understand people are people and they don't understand what it really takes to make something with your hands and have it come out looking so sweet you don't want to part with it, let alone sell it. If you make something look easy.. People assume it is easy and they aren't willing to pay you a premium for you expertise.. If you make it look difficult and can promote your expertise (though the work is not very good or is good) you will end up far better off.. I knew a guy who did very shoddy forge work, mig welded everything together and charged big money and was so busy it turned into a big success and retired with money in the bank.. I've learned over the years.. It's the self promoters, and networkers that do the best even if their work isn't as good as somebody else.. Some how they convince the people that the work is better though I wouldn't put it in my outhouse.. It's the human connections that get, keep and sell business.. People like the down trodden, the underdog as they can sympathize with them,. People have a hard time with talented people which either envy or fear keeps them from connecting with.. Or you have to make a product no one can find anywhere else.. But first and foremost its the human connections.. I took 12 years off from being a professional smith because of not one particular job but many particular jobs.. I was robbed of vision through my own misunderstandings.. Some people have it some don't.. I know where I stand.. -

Wrought Iron Wheels/ rims

jlpservicesinc replied to BOB T's topic in Blacksmithing, General Discussion

I hate to highjack threads.. I try to stay on point but there is just so much information.. the post I made earlier on Wrought iron and why it's a great material was posted from my car in-between jobs.. Rebar comes in all sorts of classifications.. There is high, medium and low carbon rebar.. One also has to remember what rebar does.. in layman speak "concrete cannot sustain elongation loads or tension.. only compression".. Rebar makes it so tension and elongation can be handled by the concrete If you find a good sample and can get some then go for it, I've made decent quality swords from it with differential heat treat.. Show nice hardening line with polishing.. Certain rebars can be tough to weld.. Anyhow, the rebar depends a lot on where it came from as well as when it was produced. there is some real garbage out there. but also some really nice stuff.. I found some rebar from way back that was carbonized wrought iron.. It was priceless for any knives or wood working tools.. Same can be said about rail road spikes.. depending on where they came from (high speed rails, heavy hauling rails) will dictate which kind of spikes they use.. Basically if the material is unknown to the user and does not have a spec sheet (even with spec sheet one should verify their heat treat methods to achieve the best results) with it then it should be tested as any good smith worth his or her salt should do automatically before they make something out of it.. Did I say I was old school.. Your welcome.. I love mystery metal.. just made a new hoof knife out of a lawn mower blade.. Wouldn't harden in oil.. LOL>> Water hardened only.. only took 3 times to figure it out.