ede

Members-

Posts

254 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

Recent Profile Visitors

4,833 profile views

-

What, Thomas, now Glenn?! My condolences to friends and family.

-

Thanks for the tip-off on the name of the gentleman who invented this. Your post, while without pictures, helped solve the riddle for me.

-

Which rosebud should I get for my new oxy/propane rig?

ede replied to ede's topic in Welding Equipment

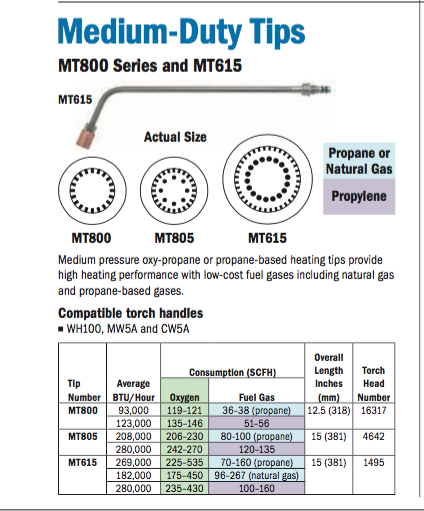

I have the WH100 medium duty torch body so all these rosebuds are compatible. -

I have a medium duty Smith torch and have been debating which oxy/propane rosebud to switch to since I am making the switch for heating from oxy/acetylene to oxy/propane along with new T-grade hoses to my gas saver. I was thinking of purchasing the MT800 although Smith has stopped manufacturing them, I think I found a source. However, the MT 615 sounds appealing if I could adjust the flame so it's not using so much consumables, then I could turn up as needed. Thoughts?

-

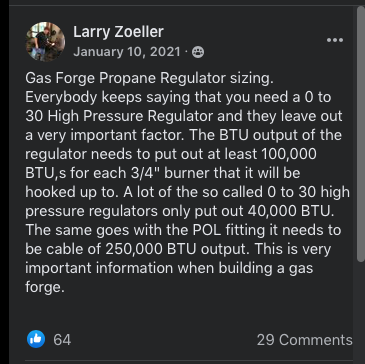

I'm glad to hear reports that folks like them. You are right Frosty, I could not manufacture a hobbyist forge for that amount of money, nor would I want to try. I'm not in the forge building business though, but I have built forges and burners in the past including your T-burners. The question about the performance of the regulator comes from seeing a FB post from Larry Zoeller regarding regulators.

-

I have seen youtube promoters with this forge. I respectfully disagree and believe the health and safety of potential buyers should come first, thus the comment about what appears to be a very thin Satanite coating. I haven't used Satanite so am curious on feedback. The veracity of any manufacturer claims should be a healthy dialogue in a forum dedicated to gas forges where health and safety is paramount. If you read threads in this forum, minimum fire blanket is usually suggested at 2, 1" layers. The Volcano forge appears to be 1". Folks who don't have forge building knowledge and are looking for an efficient forge should be aware of this, don't you think? This isn't too disparage any manufacturer, it's to find out from those more informed than myself. I'm one of those folk who doesn't take things on face value, I like a diverse dialogue before I develop an opinion, the pro's and con's if you will. I'm hoping some more experienced builders will chime in on my questions.

-

The issues I see, and correct me if I'm wrong, are: Low pressure regulator. Why include a low pressure if you gotta buy a high pressure one? What appears to be 1" of Ceramic Fiber. Isn't the industry recommendation 2" minimum? Satanite coating looks very thin, Isn't 1/2" minimum recommendation? What is a Magma firebrick? Insulating, non insulating? "True swirl flame", burner isn't tangential to the hexagonal body. Fancy advertising malarkey? Built in the USA or made in the USA for $88?

-

I see a youtuber/promoter advocating the purchase of the cheap volcano forges. Does anyone else see quality issues with them or am I alone? Model: Hero Built in the USA. Complete Propane Forge Kit - heats up to 2400°F Stainless Steel Construction | Size: 9.5 x 8.75 x 8.75 KIT INCLUDES: 2lb Satanite Refractory Mortar - for Initial Coating and 8 oz - for future Maintenance 1 inch High Density 2600°F Extreme Heat Ceramic Fiber Blanket One Extreme Heat Magma Firebricks, Propane Hose with 0-20 PSI Regulator, 8 oz Winterized Rigidizer Concentrate

-

I just purchased a 100lb LP tank to be used for dual purpose: Treadle torch with gas saver. Acetylene was too expensive and I found out that I was using too small of a recommended cylinder per Smith's recommendation of: "Acetylene must not be withdrawn at more than 1/7 of the cylinder capacity per hour (50 SCFH for a 350-cu.-ft. cylinder)." Get back to running my propane forge until I finish repairing my masonry forge, plus, the extra heat in the winter. I have used a t-grade hose in the past and want to switch to something a little more protected and do a run of 20 feet to the LP rated gas saver for the treadle and then a flexible line to the torch. Should I do a copper line to the gas saver, then t grade welding leads? I also will be adding a Y connector to do a separate line to the gas forge. In the past I have used a red t-grade hose and I've notices some stress cracks by the regulator. I want to switch to something that is sheathed and do a run of at least 20 feet, any recommendations? I've actually burned through a propane tank hose that goes to a 1 lb disposable tank connected to a benzomatic. Finally, the torch tip on an acetylene tip is not supposed to be used with Propane apparently, correct? I wasn't sure where to post this since I'm asking gas forge questions and torch questions, all related to an LP tank, apologies to the moderators.

-

My shop (approximately 23'x43)'only has a 20 amp circuit currently. I'm looking for suggestions on how to go about upgrading the power in there. I spoke with an electrician and he can either use the current 3/4 conduit buried underground and run either a 60-70 AMP service to and install a panel inside or dig up and replace larger conduit and upgrade size for 100 amp service with a panel inside the shop for considerably more money. He wanted me to figure out a) My power requirements I have a very old large Canedy Otto camel back drill press (I have to look for the tag on the motor-it's currently at a friends garage. It has a very large motor to turn flat belts. I'm guessing it's probably at least 1 HP single phase). I'm looking to get a 100 lb Little Giant power hammer, which I understand runs best with 5HP motor so I'll probably need a 220 outlet here. My blower is about 3.1Amp 60HZ with over 500CFM, probably overkill for a single forge but it works well and what I got. Would like to upgrade the lights to LED, the Shop is only 20'x40'. I want task lighting and general lighting. I have an industrial Belt grinder that is 3 phase. It is currently 460 Volts, 2.8 Amps running a 2 HP motor. From My research I have two choices, 1. A rotary converter and 2. A VFD Kbac 27d if 1.5-2hp I would like either a horizontal band saw or power hack saw Radiant Heaters for winter My welder is a Miller 211 that can be used with: 230 V, 25 A, 60 Hz, Single-Phase (I would prefer to utilize 230 V) 120 V, 20 A, 60 Hz, Single-Phase Granted I won't be running everything all at once so I'm thinking the 60-70 amp service would be okay. Adding more tools down the road? Anything I am missing? Not really interested in adding a hydraulic forging press. b) a map of the openings (where I want the outlets) Any suggestions for layout or any additional advice? Thanks in advance

-

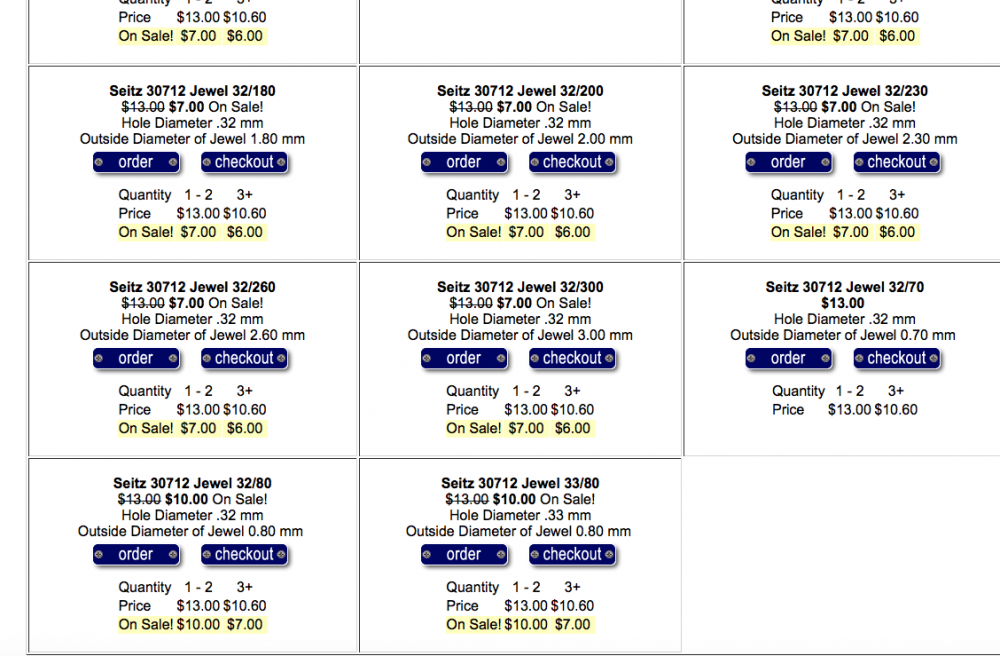

I was going to suggest jewels for watchmaking may have the potential to be gas orifices, you know those synthetic rubies that are the bearing surfaces for pivots. They ain't cheap though and heaven forbid you loose it! I was thinking they could be flush or gypsy set by a jeweler. The extruder nozzles sound a lot more straight forward to use if you can get em to work.

-

How did you fit your fuel line to the gas inlet since it's a BSPF threaded port? Also, what did you use to for the pipe nipple since the outlet is probably also BSPF threads?

-

Where did the photos go?

-

Oh nice! Mikey helped me with a 3/8" canister mount torch conversion, which connected to a universal torch extension hose, however those hoses go directly into the regulator and it seems like the needle valve or something somewhere is regulated. What size EDM tube did you use for yours and what CU IN size forge you plan to put these in? Will send you a PM on who you bought those couplings from, I may want to play.

-

ede started following 1/4” burner with choke build. Picture heavy

-

Nice build! Is the recommendation to use EDM tubes instead of mig tips now, or is it because you went down to 1/4" burner size? Also, it looks like you have a conical nozzle is the first photo but did not use it? Where did you find your stainless coupling?