-

Posts

5,772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

Forging with square steel tubing

jlpservicesinc replied to Bill in Oregon's topic in Blacksmithing, General Discussion

SQ tube also depends on wall thickness.. Different wall thicknesses offer different side profiles.. Steel shot inside the tube is much cleaner Vs sand but not as cheap.. if you use anything loose like sand or shot you have to cap the ends after filling and compacting to get the best side wall support. -

Forge tool (rake,straight poker and shovels)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

I'm with ya.. Funny thing is with being a farrier the blacksmithing is a much easier gig.. If someone wants real crazy try being a farrier.. -

Forge tool (rake,straight poker and shovels)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Thanks Robert... I got a little crazy.. Thanks Kindly.. Heart punch and heart drift.. clean up with rat tail file.. Thanks,, Me too.. Be nice once I can get the brain to get back into focus (it wants more options when only one is correct).. The arms are working well (muscle memory).. but the thought process is still a little slow.. Of course I'm 10 years older so maybe that plays in.. -

Well after this past week today was a great day to get out in the shop and do some making.. Since I offered to make the forge tools for the NEB group it was a good day to get started.. I made 4 handles all of a different design though 2 share the same concept.. Well maybe 3 if you consider a twist a concept.. The 4th tool was just to have at it and push the boundaries.. Feels good getting the cob webs off the old brain and things are starting to make more sense again.. Lot less hits on the anvil to maintain cadence and lot more work being done at each heat.. Anyhow, I made the 3 rakes today and 4 straight pokers.. The rakes were a lot of fun to make and the last one was especially fun.. a few more forging days and I should be back in pretty good shape.. I'll add the shovels to this thread at another time since I still need to make them.. still not sure on handles.. Shovels can take a little longer to make since I have to make all the parts.. Ah..

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Nice job on the rake.. Like the handle and twist design, you spent some time on it cutting in the line in the handle and such.. I find it is less tiring in use with the offset hook maybe you will find the same thing.. In overall reality the handle design (comfortable, plenty of leverage) can play a more important role (straight vs looped) but the tool as a whole makes or breaks the design.. Nice execution.. Thanks so much for sharing..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Excellent work.. Love seeing artistry..

-

the video is crappily done.. I did it a few years ago to show an online group how to make chain.. Really the best part is the very beginning and the very end where I test the chain I just made.. There is/was actually 2 videos the 2nd one was better.. I actually took off over 10 years from the blacksmithing.. Didn't touch a hammer or anything so the skill set is only now starting to come back.. At this point I have forgotten more than I know. Getting the new trailer up and running will allow for me to have somewhere to work till the shop is up.. anyhow, i"ll make a new video and post it. We'll get you something else to watch..

-

I posted a video on chain making somewhere.. You tube or else where a few years ago.. Also one on tong making.. Really a lesson is best. I gave a lesson to a guy at the last NEB meet and he got his first forge weld under his belt..

-

to correct this it just get another nail in the crotch at the split.. there is another nail under the group of S hooks.. Yes it was successful.. Thank.. Thanks.. You'll get there.. keep practicing and a lesson or 2 and you'd have it solid..

-

Had to test out some new welding flux..Made this from 3/8sq and 1/4" sq.. Few S hooks and nails thrown in for the fun of it..

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

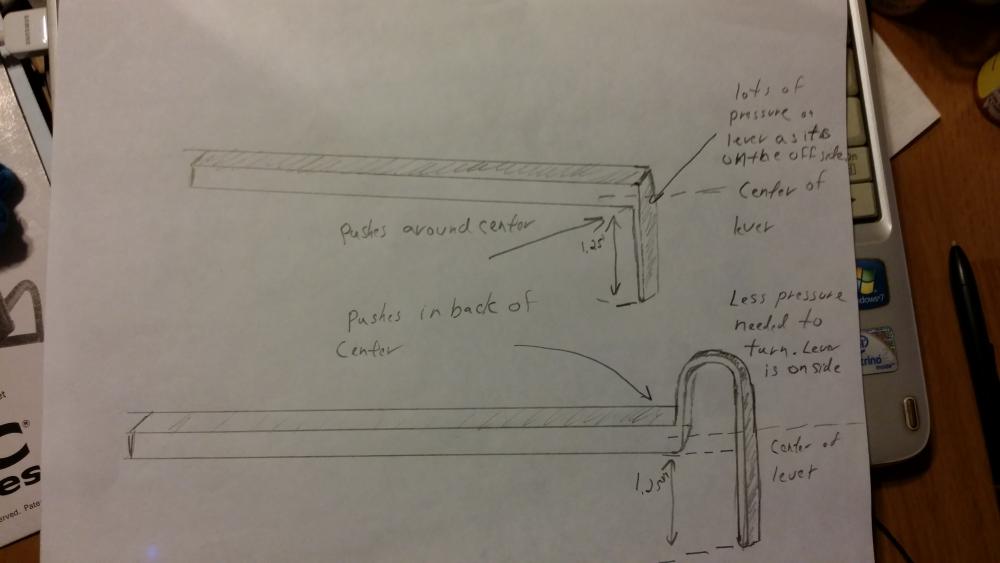

Sorry if I sound grumpy.. OK.. I'll try this one more time.. Torque is the amount of twisting force as measured in ft lbs, inch pounds, Newton meters so on, and so on.. A lever with a fulcrum.. IE : Balance beam.... 100 lbs at each end with a pivot or fulcrum in the middle with this beam exactly in the middle should be even both sides.. If you don't change where the fulcrum is on the board supporting the 100lbs on each end. But make one side of the board longer.. Now because one side is longer that 100lbs has a greater weight advantage.. This mechanically adds more torque to the area in contact with the pivot and as the stiction is overcome the longer end will start to move towards the ground.. The same is true if we keep the board centered and instead of having 100lbs at each end of the board we have 100lbs at one end, and we put 200lbs at the other end.. Now if the board is 20ft long and we move it from the middle and we move it 10ft towards the 200lbs side the beam with the weight will now be balanced.. but one side will be longer than the other but still in balance.. So, by offsetting the hook to the back side of the shaft.. You are actually moving the pivot point.. While not that far it does add up.. So, again.. it doesn't matter whether the hook is offset or not in use.. But, you can add more torque to the shaft and since the pivot is not moved further along the lever you can put in more less perceived torque when you turn the shaft and get more power at the end.. Vs at a 90D to the shaft.. But, since it's the handle you are holding that can feel good in the hand the hook end plays very little into how your hand feels on the handle and perceived power being put into the handle to turn the rake.. I don't use a rake as my only forge tool.. I use it to shuffle around coke and coal but usually just to pull clinker out, break up large coke lumps but that's about it. Oh and poke holes in the top of the fire.. My recommendations are to make a handle that is comfortable that you can apply ample power (CONTROL) to and it doesn't make your hand tired.. Remember when you work, each items you have to use should enhance the job at hand and not tire you out any more than needed..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Boy, what is a girl to do.. Please go back to the drawings.. The distance from the fulcrum to the point is the difference.. if the handle is in the center.. Or the pivot. then in theory you would gain a small advantage vs a bent 90d straight off the shaft.. Since the fulcrum/pivot point are the same as the center of the shaft.. A bent back and hooked rake has the leverage point behind the pivot instead of in front of it like a 90D poker.. So in theory you have moved the fulcrum more towards the center of the hooked piece vs to one side of the shaft. Okay.. I can see you guys simply don't get it.. While yes, one could say a swept cast iron spoke was done that way to offset some of the forces of the casting cooling.. it's not only castings that were done that way. and it goes way beyond why cast iron has swept spokes.. It also has to do with torque transmission, etc, etc.. . It has to do with how a swept spoke will lead a socket/shaft around vs a straight spoke.. A swept shaft on a handle will pull or push in a straighter action than a straight shaft which will create more of a side load as the shaft center pivot since the handle is mounted to the opposite side.. Really the whole thing is irrelevant.. Just sharing the knowledge but you guys have to be willing to do some homework on your own.. The tire thing works on the same principle.. Anytime you move a pivot onto the other side of a pivot,fulcrum, etc etc.. the force becomes less on the other side.. It will ease the work at hand.. I don't know how to explain it any simpler than I all ready have.. Don't believe me make 2 poker's exactly the same except put the hook on and learn for yourself.. Sorry but really I've had enough of the whole thing.. Make pokers how ever you would like. It's all good.. Sorry, and not to be rude, but this isn't something I find important enough to spend any more time on.. Thanks for all the replies..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Buzzkill, Any luck? I"ve watched old video footage of many a forge being oil fired even back into the 1920's The most recent was of an axe company in Maine that ran into the 60's.. They used oil fired forges.. There has been more technology that has gone to the way side as modern innovation has taken hold.. Funny we still use coal forges, wood forges, gas forges right.. When will a solar forge be developed??? Anyhow, I'd love to see how they used to do it.. I still have a gasoline blow torch which I used to use all the time.. It's only since i moved into the new house that I stopped using it simply because the leather finally wore out on the pump.. I think anything can be safe (lots of things were used for 100years safely) as long as you understand the procedures and/or the assumption of risk is taken into account.. From what I understand, the oil can be be fed via gravity though it is ran through a heat exchanger of sorts before it reaches the fire.. But again I lack 98% of the information to be helpful..

-

Like Frosty said.. Looks good.. As for the welding heat thing.. You can also use a long straight poker with a flattened end with a little flux on it and as the metals come up to tempurature you can use the straight poker to see where it sticks.. When you get ot the right temp the poker will stick and you will have to twist it off.. Sure sign you are there..

-

German made Trenton.. I have one in 155lbs... They are a nice anvil.. Enjoy.. Welcome to the group..

-

nice work.. Love to see a different take on things.. Love the colors.

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

George, Nice rake.. I find I like my rakes to about long enough to go from the far side of the firepot to the forge on my side.. This seems to be the theme I follow.. average length seems to be about 26".. I have 4 of them and 4 straight pokers on the forge.. I know I have 1 of each from the shop, but don't remember when or why I made the other ones.. You did a great job on twisting it up.. Cold or Hot? The loop handle like that will give pretty good control.. I usually turn the work end 90d to the handle this way the handle lays flat in my hand.. The forge setup looks nice.. Hows about a few of that as well..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

From Wikipedia law of the leverEdit The lever is a movable bar that pivots on a fulcrum attached to or positioned on or across a fixed point. The lever operates by applying forces at different distances from the fulcrum, or pivot. As the lever pivots on the fulcrum, points farther from this pivot move faster than points closer to the pivot. The power into and out of the lever must be the same. Power is the product of force and velocity, so forces applied to points farther from the pivot must be less than when applied to points closer in.[1] If a and b are distances from the fulcrum to points A and B and if force FA applied to A is the input force and FB exerted at B is the output, the ratio of the velocities of points Aand B is given by a/b, so the ratio of the output force to the input force, or mechanical advantage, is given by {\displaystyle MA={\frac {F_{B}}{F_{A}}}={\frac {a}{b}}.} This is the law of the lever, which was proven by Archimedes using geometric reasoning.[2]It shows that if the distance a from the fulcrum to where the input force is applied (point A) is greater than the distance b from fulcrum to where the output force is applied (point B), then the lever amplifies the input force. If the distance from the fulcrum to the input force is less than from the fulcrum to the output force, then the lever reduces the input force. Recognizing the profound implications and practicalities of the law of the lever, Archimedes has been famously attributed with the quotation "Give me a place to stand and with a lever I will move the whole world."[3] The use of velocity in the static analysis of a lever is an application of the principle of- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

We digressed.. Please don't make assumptions on ability or knowledge.. The idea wasn't on how to change a tire or the right way to do it nor the way an air impact wrench works.. The lift or hoist as you called it irrelevant to the diagram I posted.. It was a way to suggest how in a simple way to see the advantage of moving the leverage point behind the handle with an offset.. I explained the operation in full detail in the post.. All I suggested is": If you want to try it.,. If you don't see the advantage.. Try it on a tire with the wrench or torque wrench on both sides.. as in the diagram.. I never mentioned on tight lug nuts or lug bolts.. Please forget about loosening them.. In the example the tire is getting put back on or the lugs are all ready loose.. LOL>. or If you can figure out a simpler way to explain it be my guest.. Glad you like it.. Thanks- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

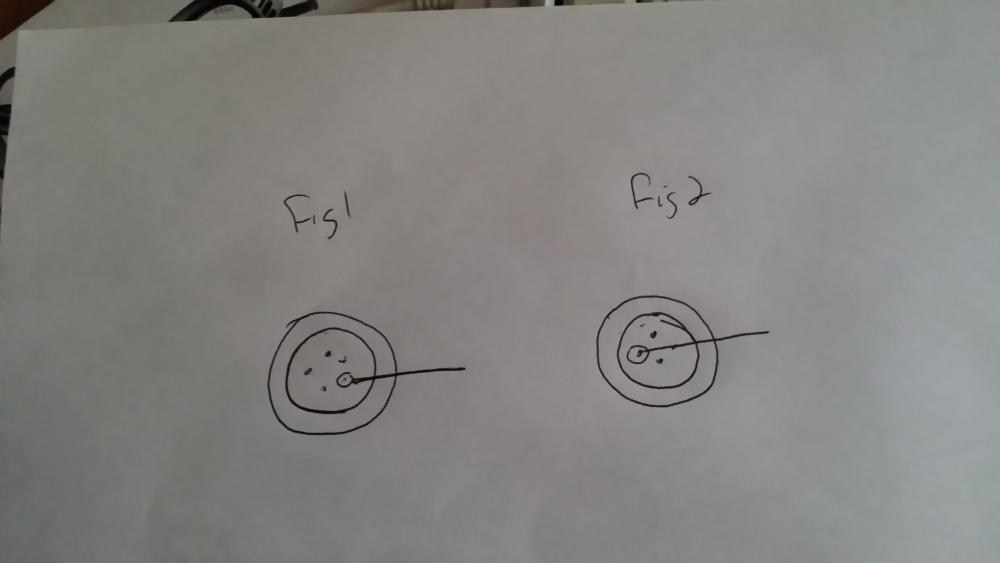

Yes and no since you aren't using mass to move it. if the tire was in motion then what you wrote would apply as you stated inertia.. As then youd being using the mass of the rotating tire to break the lug nut free.. If you substitute torque for inertia then the answer would simply be "Yes".. In my example the tire is stationary and you are holding the tire with one hand while torquing the lug nut after putting the rim back on the car.. Same applies when loosening the lug nut but you would never be able to hold the tire and break the stiction of the nut and rim.. It's why I used the tire all ready off and putting it on and torquing to value.. there is also a leverage ratio which gets applied as the lever moves by the rotational center of the mass since it's actually a dual orbit affair.. (around the center mass, and off center of the rear of the shaft.. This creates a convergence point if both bodies were rotating or there was the ability to clock the pivot points as in the picture.. center orbit of the whole tire turning. (same as twisting the poker at the center shaft) offset center of the back of the shaft (lug nut/bolt location), and then simply rotating the second point (work end of poker long side) . If you were to look at the end of the poker it would align with the figure 2 vs figure 1.. and figure 1 would align with the blade only coming off one side.. Anyhow, I've had enough.. My brain hurts.. It just works..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

It does make it easier.. Look back at the drawing and while it looks deceptive it actually does work.. the weight has nothing to add as far as a turning tool.. In smacking coal it does.. If you look at how old hand driven items and how there handles were swept away or towards the direction of travel (away was the preference) vs just a straight handle.. There is actually a science behind it and wasn't done simply as a decoration.. Your going to make me break out the geometric function of levers and pivots aren't you.. ?????????? The easiest way to explain it is: If you have a car tire up in the air with no brakes on and you are tightening the lugs after you have taken the old wheel/rim off.. If you put the lug wrench on the off center side (fig 2) You can hold the tire more easily than if you had it as in figure 1.. The tire example is a great one.. If at some point you still don't believe.. Give it a try see which is easier to hold.. You will find that Fig 2 is the easiest almost exactly at the center line of where the lug nut/lug bolt and the center of the axle are in alignment. about 40 degrees of arc swing through this center will offer the proof.. Near perfectly centered is where you will be able to put maximum torque on the wrench while still holding the tire fairly easily even if torqued to 80-90ftlbs as recommended by most auto MFGs.. Forget about holding tire in figure 1 at those torque values unless you are a hulk..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Frosty, I'm just getting ramped up.. I've been sleeping for 10 years so the skill set if rusty.. LOL no pun intended.. Ok.. maybe a little bit.. Thank you.. I actually have 3 touch marks small anvil, large anvil and 2/2 or 2 dots over 2 dots as a representation of zero.. In the olden days it was considered a travesty to make a beautiful peice than deface with a makers mark.. So the 2/2 can be seen as a decoration of sorts, yet is my mark just the same.. You can see it clearly here on the spring lock.. My pleasure.. Love to see your item when/ if you make a new one. I will be making a few more as I believe I will be making some more as well as shovels to donate to the NEB for the new forge setups they have if they approve my offer.- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Post one up when you have a chance.. Love to see it.. I leave a rounded end on the work side.. I used to do an offset bevel, but found I didn't use it enough to have it.. I use a shovel, rake and straight poker/welding feeler as my forge tools..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Thanks guys.. Was fun to make and a great way to use up the rod which was discarded.. Smoggy, the reason for the offset hook is so you have better control over the hook end.. with it offset to one side like you mentioned the pressure applied to the tip is pushed either left or right around the center mass and since the hook is on the down side. With the hook mounted to the back of the shaft. (back being the side you are looking at in normal use or tip down) the pressure is moved to the back and it re centers the hook which now moves the pressure more center line to the shaft vs being offset only on one side. This little thing can make the tool more user friendly and take some pressure off the wrist in use from lateral (twisting/torque) forces.. I like all my forge tool handles to feel like I can pry up an anvil with them.. I found in my early days that a handle that doesn't offer positive control are harder to use and I found my forearms and wrists were more tired at the end of the day.. So no round handles unless they have some way to prevent a twisting force. Like the hoop end.. The drawing explains it a little better.. The 1.25" measurement is just to show how the lever applies the forces a little differently. the number is kind of arbitrary since it comes down to what someone likes.. Each leg from the shaft in the drawing is the same length and the reason I measured them and they are as drawn 1.25" long.. Also some would argue it doesn't matter in a forge tool since it sees so little use..Need more pressure for turning just put on a bigger handle.. I just do what I have found works better for me and besides that it looks neat..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

-

Forge rake (side poker)

jlpservicesinc replied to jlpservicesinc's topic in Tools, general discussion

Thanks. . It's very comfortable in the hand.. the ring sits right in the palm and gives good control of the shaft in use..- 30 replies

-

- forge tools

- side poker

-

(and 1 more)

Tagged with:

.png.c95654babe8bffd229c4d0c3e739f85a.png)