-

Posts

9,760 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Daswulf

-

Correct Anachronist. A real anvil. It works. BigGun, I did not know.....

-

My next Jeeping trip to the mountains I think I'll go anvil hunting. I know a good spot by a river. I'm only limited by what I can lift.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

IFI sells a shirt, " Hold the cold end and hit the hot end, Get it right next time!" I know I have been guilty of grabbing something that was hot before. I've got better at letting go quicker. -

The key it to just get a good heat where you want it to expand. ( for me usually just on an end) Use a water can to cool any area outside of where you want. I do mine with the heated side down on the anvil and fairly rapid taps on the top of the piece. Not heavy blows. It does like to bend a bit so just correct it as you go. I have also heard to turn the piece as you hit it. This seems to help a bit but a lot of times it still bends a bit so I just correct as I go. I wish I was better at explaining things.

-

Well who said it had to be granite? The face doesn't have to be polished. Just makes for nicer final work. Fine... I'll find an uglier rock.... If you did want a piece of granite I'm sure a grave stone cutting place has some mess ups the might part with cheap. And granite counter top is just too thin to use as an anvil.

-

Thanks Seldom. Donnie, I'm doing this for that reason And experimenting. Don't know if you could see it in the first pictures but this chunk had a minor crack from the start so I guess I "bought" a damaged anvil lol. Still, it held up to my attempt tonight to forge tongs out of 5/8" rebar. Why rebar? Because every other new post mentions rebar. Ok, ok. I have some minor skills under my belt, I had to try tongs without using tongs to make them out of rebar. ( first attempt at that) BigGun, the edges did not like the rebar being made into tongs and the edges gently spalled on me.( broke the edges, not exploded like concrete can spall with heat) so the flawed granite anvil took some damage making tongs out of the rebar, but it held together enough to make another s hook using the tongs I just made on it. And will still hold up to more abuse. I used different sized nuts as a pritchel hole and to start making the rivet, as well as true up the tongs. The tongs are ugly but function fine. I also stuck with my $2. Fleamarket find hammer, with an undressed ugly face. I could have tapered the tong handles but it was taking a while, and they could be functional so I moved on because I could. All in all the granite chunk is still functional and I will use it again. If I make more on it I will post it here.

-

and someone said a Hay Budden is an old anvil..... I'm helping a friend of mine get started in blacksmithing. He almost has his forge all set up and wants to buy an anvil sometime soon. Today at work I told him that I found him an anvil and he got excited until I showed him the picture. After explaining, he was surprised and more knowledgeable. He can afford an anvil and I know where some are so he still wants a London pattern. Just did a ball bearing test with a 1 3/4" ball bearing and it was in the 60-70% range.

-

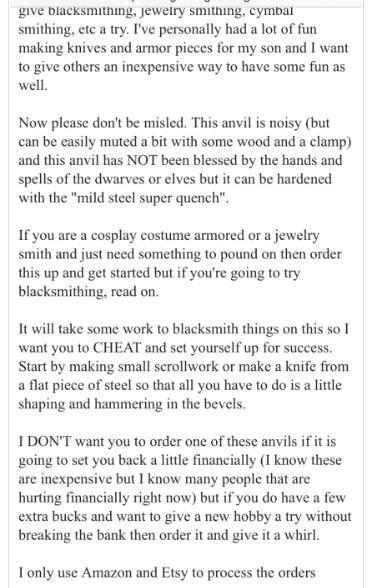

It would be horrible trying to use it as an anvil. I-beam really lacks the mass you would want. What is holding you up? money or trying to find a "london pattern" anvil? There are a lot better things to use as an anvil. a section of RR track stood on end, a block of steel, a good dense rock.........

-

LOL.

-

Nice score Notown. I had tongs show up on my doorstep given to me by a neighbor who I gave some plastic barrels to that I had been given for free. It is good to spread the word.

-

Can you be a bit more specific?

-

I agree. He made the world a much better place.

-

No spalling BigGun. I had that concern in mind. Was wearing ppe in case. More then just the safety glasses. I don't know that it wouldn't spall working with larger stock. The edges are not clean cut they are a bit jagged like it was chiped apart and with fitting the stock off with the edge had only minor chipping. I mainly stuck closer to the middle for the heavier hammering. I guess a bit rounder a rock would be better for drawing out. How can I attach this round rock to this flat rock to make a London pattern rock. Haha

-

Nope, haven't tested it. I did clean it up but couldn't find a name on it ( Thankfully! ) lol. Didn't feel much if any rebound but it was sturdy as a rock. It's much better then those soapstone or sandstone anvils that nature freight has for the taking.

-

Thomas ( Bogiron), I kept hearing that a rock could be used as an anvil and in the back of my mind I had this nagging itch to try it out. The granite was there and I was done with what I was making otherwise so I gave it a go. I was honestly surprised how well it worked. What's next? Making a stone hammer? in my off time I plan on working more with it. I mean how can you say that a rock could work as an anvil unless you really know it. Tho. I know I don't have the time to delve in too deep into the "roots" of it all.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

Ouch. Yeah that's when mistakes happen weather painful or time/ money wasting. Hope it heals quickly. -

Lol Aus, yeah proportion is pretty important for them to look good. From concept to welding has a lot inbetween. And some after. And standing a 24" pipe wrench up ( let alone a 36")with a curved tail while trying to tack on legs in the right spot can get tricky. a twisted sense of humor always helps, and some cold beverages.

-

That is a beauty! I wouldn't mind having to get used to that vise there.

-

Nice one Aus! Looks like he stands out just right. People that see it will probably wondering. I bet they would sell pretty well. If you need a little mass on the end of the round bar just upset it. And as usual, eye candy in the background

-

Funny enough I started this craft through wanting to forge blades and now I have found other interests in it. If I ever hand anyone a blade that I made to use I think it will be about the 30th one lol.

-

Welcome aboard.There are threads on forge welding here and many Good answers as well. pack a lunch and a cold drink since you will undoubtedly be able to find info here that you need to be successful. Don't forget to add your location to your profile since there may be other blacksmiths or groups in your location.

-

Very nice work Chris. I've said the same thing lol.

-

I have seen blades done both ways with and without some hammer marks. your choice, I would think. I see improvement. I'm also no knife maker and can only speak from my untrained yet knife loving opinion. keep these as is, improve on the next. The bowie could look better with the grind cleaned up after HT. They look good IMO for 4th and 5th knives. keep at it. always work to your best before finishing them. On knives, pushing it through and thinking about it after dosnt seem to work out to the best. Keep up the good work. just an untrained opinion.

-

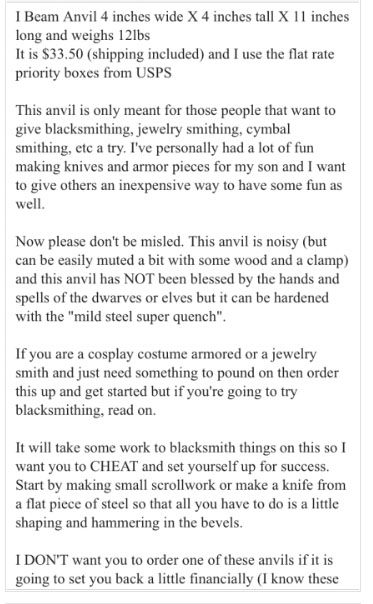

LOL yeah there was no ringing. It Is a real anvil.. because it worked as one. Might have to sell it on Craigslist. it would be way better then these two That are still up! UGH! Really?!

-

Thanks OSC and Joe.