-

Posts

1,633 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Nobody Special

-

Polish with a tennis ball or similar such and sand paper attached to the outside, on a drill. Change size of ball as needed. Or could make a tumbler...

-

I admit, I like watching shows like this and screaming "What the **** at the tv when they do or say something silly." It's bad tv. Oh well. (also read casting the One Ring whilst talking about forging it in the fires of Mordor, and Valyrian steel, and while we're on GoT, mix and matching armor styles from about a dozen different periods, often on the same person), hitting cold steel in the cowboy flicks, quenching for no reason to add drama, London pattern anvils in Roman or viking flicks...) Also, I thought he said he was deliberately trying to pit it, in order to falsely age it? Was he using muriatic? I just assumed it was hot vinegar, but wasn't watching close. Makes sense it was something stronger though if it was pitted.

-

What I was given to understand, grant you this was filtered through belligerent NCOs years ago, was that you usually smell it when the dosage is fairly low, hard to smell in higher concentrations. And if ya smell mown hay, say in your urban forge or while welding, with no one running a John Deere, instead of say, near a hayfield, might be a warning sign. If you smell grass...well, at the least, make the culprit stay away from the power tools for a few hours.

-

WD40 can also offgas phosgene when heated, and an effective detector, if not one you want to use, is your nose. Smells like mown hay.

-

I find they usually want the hoofpick flattened on the end, rather than a point, and I've had a couple of people ask me to make one on each end, pointing in opposite directions. Or put a bottle opener in em. Meh. Off to a good start, sir.

-

I've got metric and standard (imperial). Just the big boy sizes that you usually run into in auto work. It does get you close, but if I say need 24 inch lbs and my big wrench is one lb off, I may be 50 percent off, instead of the say 3 percent if I had a large bolt that was supposed to go to 30 ft lbs. Not good when adjusting transmission bands. Or to make it more metric, I needed one that read in Newton centimeters instead of Newton meters.

-

A lot of China's stuff is good, great even. Ya just got to remember they've got a third of the world's population, and much of the industrial production. Add that in with the fact that you can get expensive quality stuff a lot closer without all the nasty tariff fees and shipping... Well, we get a lot of the junk and counterfeits, stuff designed specifically for selling to people looking to buy cheap imported crap. Better still, keep quality control low on it, and they'll buy another shortly. Fer example...Got to working on a transmission in a 99 Dodge the other day, and found myself in need of a torque wrench that would go in inch lbs. No problem, headed to Lowes. Nope. Home Depot? Nope. Autozone, O'Reilley, Ace Hardware, (really, really starting to cuss Mopar at this point...), no luck. Looked online and could find one that would be there in 3 days. 120 bucks. Local Sears could get it in Craftsman. 3 days, plus the contents of your bank account plus your firstborn child. Pep Boys...$200, and it'll be there in 3 days. Harbor Freight though? Had a cheap Chinese knockoff, $14 and a 20 minute drive. I know it's junk, I know it'll go out of calibration on about the 5th band I adjust, but... It doesn't help that you can't get a lot of tools or supplies anymore except by an expensive order and shipping, or at one of the discount places. My local box stores have stopped carrying at least - hammer handles, steel wire wheels for a bench grinder (they have brass coated), any wheel for a bench grinder but coarse, carbide drill bits, fencing tool (the little plier/hammer doodads for box wire and staples...), firebrick, thermocouples for water heaters, umm......i don't remember, every other time I go though, they've dropped something from the inventory. It's starting to feel like when you walk into one of the Hobby Lobbys looking for yarn or beads or such and run into 20 acres of plastic plants instead.

-

1. I'm sure your grandfather was a great blacksmith. 2. No, I'm not shoeing horses. 3. Yes, I can make a sword. You can't afford it, but I can. Who do you want to kill? 4. Yes, the fire is real. 5. Yes, really real. Get away from it. 6. That's hot. Don't touch it. 7. Told you it was hot. Don't sue, I'm broke. 8. Well, wrought iron has low carbon and you can't really get it anymore. Steel has a crystalline structure that shares electrons, and forms around carbon in a specific...you know what? I'm just gonna save us both some headache and refer you to Thomas Powers. 9. Because it takes 10-15 hours of my life, plus the forging, the bit I enjoy is the shortest part of it, and the one you get at Walmart isn't custom made. 10. Yes, I know I'm on fire, let me finish this bit and I'll put it out.

-

Thinking 'out loud'/Self defense for the ladies

Nobody Special replied to Michael Cochran's topic in Knife Making

I was always taught the first rule of a knife fight, is don't get in a knife fight. Run, walk, cheat, but don't get in a knife fight. When in doubt, see rule one. Using a knife in self defense is about like using the 9mm in a firefight. If it occurs, things have gone badly, badly wrong, and it's not going to end well for you. (for that matter, overseas, a lot of guys brought big, manly knives with em on deployment. They didn't do much except get used for opening MREs or getting banned by NCOs. I shudder to think of the investigation and paperwork if anyone had actually stabbed somebody, even during combat.) I've no problem whatsoever with women that are into knives or firearms, but...rule 1. I have noticed that some women prefer smaller handles or blades, some most manifestly do not. S'also true of some of the men though. -

No no no. The anvil is Mousehole-ish. The user is the Mouseholic. I second the chalk, or baby powder, flour, what have ya. Found a lot of invisible mystery markings that way.

-

Help identifying some old stuff I found

Nobody Special replied to Fuzz557's topic in Blacksmithing, General Discussion

Anvil/vise combos are usually hollow cast iron. Light work if that only. The anvil looks ASO ish, but may have a steel top. Test for rebound. Wilton's are popular, The bullet vises are VERY popular. And expensive.- 9 replies

-

- five anvils

- spike anvil

-

(and 1 more)

Tagged with:

-

Found an Anvil - What's it Worth?

Nobody Special replied to the freewheeler's topic in Anvils, Swage Blocks, and Mandrels

Drop in at the Bealer meetings around ATL, or the Redtop Mountain Forge in Cartersville. There's anvils around. Good luck with the one you found. -

-

Getting credit where due??

Nobody Special replied to VaughnT's topic in The Business Side of Blacksmithing

And on the other side of things, wasn't it Apple that recently sued Android over stealing their original idea of "rectangular phones with rounded corners?" -

Black smithing for child

Nobody Special replied to Allen1975's topic in Knife making Class General Class Discussion

Nowhere near, and although I make the occaisional knife, not a knifemaker, mostly specialize in small items (door knockers, bottle openers, tools,) and occaisionally whatever larger piece has taken my fancy (andirons most recently). That said, this is a field that responds well to the Suzuki method of pedagogy, especially considering the age and the safety issues. Suzuki method was created mostly for learning violin, but involves the idea of learning by saturation at a young age, like learning your native language. There are many parallels, but the one I'm thinking of especially, is that it includes active participation with the parent supervising practice, taking notes during lessons, and often learning alongside of the child. This might especially be important considering the potential for burns, cuts, squished everything, abrasions, and the occaisonal bit of steel or wire buried in the skin. It's rare that anyone experiences serious injury from forging and finishwork, but the constant potential for mild injury is the kind of thing that screams moderate and discreet parental supervision, and that many parents, often more so than the child are unwilling to face. In finding a specific instructor, I would ask within the Alaska Blacksmith Association, and probably Frosty on here in particular. Even if he/they don't fit directly, they can probably point you in the right direction. -

Peter Wright Anvil

Nobody Special replied to Iron Mule's topic in Anvils, Swage Blocks, and Mandrels

Most PW anvils go $3 a lb, sometimes less, sometimes more depending on condition, but big ones often command a premium, much more because...well, they're big, and hard to find. On the other hand sometimes they sell very slowly, because....whatta ya need an anvil that big for? There was a 425 lb near me for sale on CL for months, I think he started at 2100, and was asking 1700 last I checked. Think it was supposed to come out of an engine (locomotive) shop somewhere. And that one was posted under Atlanta OTP west or north, don't remember, if you're interested, Stu. -

If you have a good deal of experience and access to a foundry, it should help things considerably. There are large number of people that come to the site with no casting experience and visions of producing cheap anvils by casting them in their backyard, sometimes accompanied w questions about coffee can furnaces and fire extinguisher crucibles. Then they usually get upset when people suggest that their method might not be safe, easy, or cheap and go away mad. If and when you do, would you mind documenting it and posting? The rat hole anvils are H13, I believe, and they are "flipping sweet".

-

https://www.facebook.com/HISTORY/videos/10153285368216184/ Finally saw the darn thing. Iron and Fire. Trailer's on their FB page, link above.

-

They also have been used, used, and used. My go-to anvil turns 200 this year, There tends to be wear, tear, and compression, especially over the sweet spot that means not only can it be non-parallel, it may be swaybacked (an extremely useful condition by the way). It was not unheard of at all for a smith to turn their anvils on different angles to work with the various shapes, say using the side as a swage. As to the feet - Screws, although around, didn't really become a cheap fastener until the mid to late 1800s. Some anvils, especially 20th century anvils made from cast iron or cast steel do have mounting holes, but many saw no reason to change. A large staple over the feet can be made in a couple of minutes, comes out easily, and costs nothing but a small piece of scrap.

-

Is a $140 hammer really that much better than a $40 hammer?

Nobody Special replied to Pancho07's topic in Hand Hammers

So, sometimes, sometimes not. And that diagonal peen and some of the oddball sizes/shapes are around if you don't mind reforging or grinding those cheap finds. My go to hammer is a 3 lb that I changed to a diagonal peen following the instructions in one of the knife making forums here. At this point, I just grab whatever I see at the flea markets at a halfway decent price and modify them. Almost all my handles are modified, either changed from what was on it, or made from scratch, cut down and rasped broken shovel handles, etc. You get it the way you want it, and if it doesn't suit, well, you're out a $5 flea market find. But then again, as a hobbiest, my time has less value than my money, and I making them besides. If I knew there was one that I knew suited me well, and I was doing production stuff....well, 150 is cheap for a good tool at the right time if it makes the difference. Holds true with a lot of things. Putting a couple of bends in a wrench to get to that impossible spark plug or transmission bolt, changing tongs to work with a different shape, like that. -

Try rubbing flour or baby powder on the sides with it tilted a little. Sometimes brings out faint marks that are next to impossible to see. On some I hit it with a non-knotted wire brush first.

-

So, you would get upset like my wife when I call her palomino the orange and blonde one, the grey the white one, and the sorrel the red one? Almost as bad as when I call Tennessee Walkers the ones what walk funny and the Fresians the Spinal Tap horses.

-

Been working on some larger ones, and ground down the insides of the handles; it really cut the weight.

-

Show me your Bottle Openers!

Nobody Special replied to Arbalist's topic in Blacksmithing, General Discussion

PM sent. -

Getting credit where due??

Nobody Special replied to VaughnT's topic in The Business Side of Blacksmithing

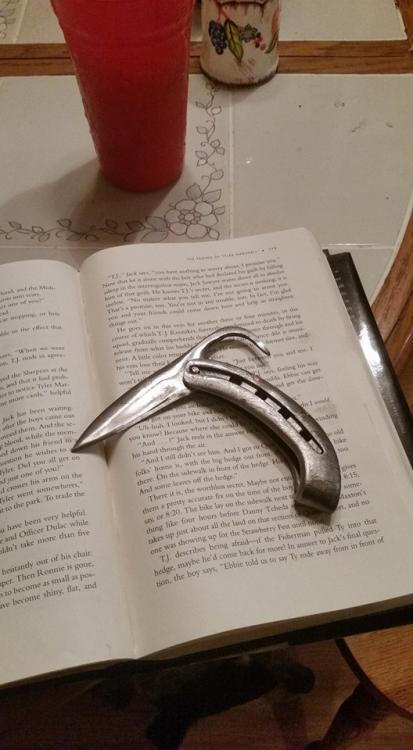

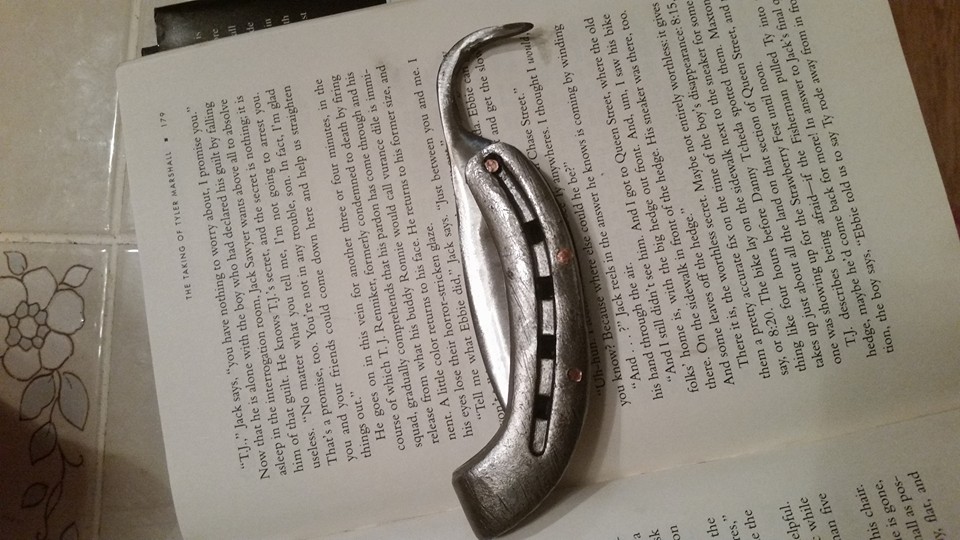

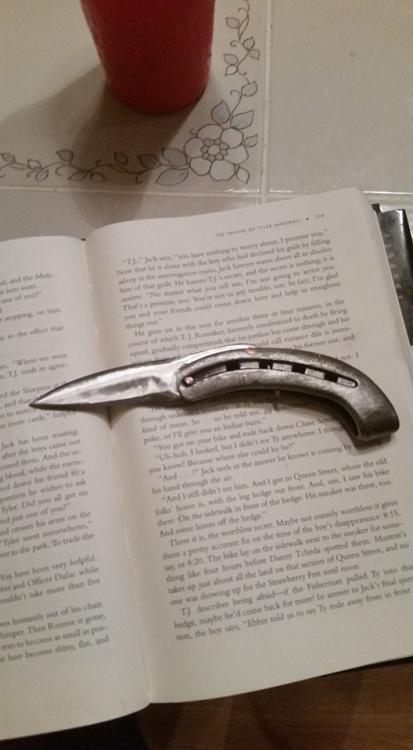

This is usually pretty clear cut on something like sculpture, or art pieces like that cool looking fang. But...what about things like bottle openers, and hammer styles? I see a lot of "Hofi-style" hammers being sold on the internet. Some of em are clearly profitting using his name to promote knockoffs, and are clearly wrong. Others are looking at it as, well, it's a general shape of hammer. I dunno, I think I could make a "Brazeal style" rounding hammer and not feel I was stealing his creativity, IF I'm not using his name to sell hammers or trying to make an exact copy, but if I were to do one like those fancy Cergol Ironworks deal with the chiselwork, is that artistic infringement? What about if I change the patterns to my own design? How about all those forged copies of say the Game of Thrones slave necklace that are floating around out there for sale (even though Danerys's was resin cast)? Or I often have people come to me and go "look at this bottle opener I found on the interwebs, can you make it?" My usual response, ummm, yeah, but let me make a few changes to make it my own. Sometimes I wonder if I'm still too close. Some of this stuff is craft, some is art, some in between, and it can get blurry. Some of it is clearcut, and making an exact copy of someone's design and taking credit for it is clearly over the line.