-

Posts

1,061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Michael

-

There's an old electric motor repair shop in downtown San Francisco, they fixed up a blower motor for me once. 160 # Hay Budden in the back on the floor. Used for driving armatures into bearings, or something like that. Been offering waist high blocks of steel to replace it for a couple of years now. I'd stop in every couple of months to see if he wants to trade or sell it.

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

Spent a couple of days in a friends shop this week. Bolting down a gorgeous, French Pig Anvil as the lag bolted chains didn't really hold it down that well. Then a lot of tapers, she would start the scroll and I'd finish it in the jig, 30+ of those scrolls. Love helping out in another shop. -

Welding cart/torch stand for my oxy-propane rig

Michael replied to JHCC's topic in Welding Equipment

The 'clear as ' metaphor that always comes to mind is 'clear as a glass bell, on a cold night, in Montana, before Statehood' but it works for Alaska too. -

-

I posted this back in 2015 on another RR spike thread With proper credit to the Kootenay Blacksmiths Association. I keep a print of this out in the smithy for inspiration

-

from the local building material salvage place. I'm guessed the ring was a part of an anchor chain or maybe some dockside hardware (wearing a buddy's anchor forging project T shirt might have been an influence), but thinking on it a bit, I think its from some lifting or rigging gear. Might be a useful shape in the smithy, might just end up as a tarp holdown weight.

-

Nice space there Red Pedro! I'm looking to build something similar in a corner of the yard, and free up the patio for the family. Did you build yours (assuming you built it) as a pole barn, with the posts sunk in the ground or concrete? I don't suppose drainage is much of an issue where you are. Slowly moving out all the dirt to get ready for drainage gravel.

-

I also have a stainless half keg with the end cut off for a slack tub. Best one yet! Killed the prior mop bucket by accidently dropping a BIG clinker in it, on the way to the clinker bucket, and burned a hole in the bottom.

-

I live in a place that rarely gets to freezing and not for very long when it does, but I've read that a wooden stick, any piece of scrap really, stood up in your quench tub will keep it from freezing solid. Never had to try it, YMMV. At the very least a length of 2x4 at hand will make breaking the surface ice easier.

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

Sounds like a good day! -

In terms of a good rain cover for a JABOB, or JABOM, I have found that the 3x4 foot Steel or Aluminum drip pans from the auto parts store, to protect your driveway from oil leaks (or cars "marking their territory") make great forge covers, often with a lot of overhang and pretty easy on and off.

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice arrowhead Nathan! For work holding, I'm a big fan of a weighted chain across the face of the anvil. might be a little slippy-slidey across the small, rounded face of a sledge hammer head anvil though. Bicycle chain works (and might be better sized to your anvil) until you can find motorcycle chain. Mine is fastened to the near side of the stump with the weight on the far side. Maybe an open ended hook on the far side to keep the chain lined up with the anvil face? Chain will hold your work still, not necessarily securely, but enough to get that first punch dimple where you want it. Remember the chain over the work is HOT DAMHIKT (Don't Ask Me How I Know This) -

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

As long as you don't lose too many arguments, I think you're good. Chimaera-he does look a lot like Kerbal Space creatures, Bug eyes would be great, hard to do by punching, maybe rivets? Been trying to figure out a forged Dalek (nerd alert) and those have a lot of 'frighteningly convex' shapes. -

Restoring Incomplete Starrett Dividers Compass

Michael replied to Cleave's topic in Tools, general discussion

Great work! Nice save on an old tool. Impressive addition of the WF Barnes lathe comment by the way (Velocipede in the shop here) Bookbinding buddy of mine recently tried to piece together odd ball parts of dividers like this and ran into odd little differences in different years of manufacture. -

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a little Forge Buddy on Monday. 3/4 square and 1/2 round. Pretty straightforward after the Anton Yakashev figure the NWBA demonstrated in November, and I spent most of December completing. This makes for 6 or 7 figurative projects since lockdown started (and forge access has been 15 feet out the back door all day!) -

Anvil hold-down treadle

Michael replied to Owen Hinsman's topic in Anvils, Swage Blocks, and Mandrels

Another 'junk on hand' hold down. Motorcycle chain nailed to the stump on the front, the cast iron weight hangs just above the ground on the other side. Chain usually at the step or back of the horn when not in use. Square tube is my "bridge" fixture for fork tines and the like. The foot of chain across the face WAS painted red in the last incarnation of this hold down, haven't had to on this one, the recollection of grabbing too close to the hot part is still fresh in memory. -

Vegetable oil as a quench oil?

Michael replied to Car23l's topic in Heat Treating, general discussion

My local burger joint was happy to give me 5 gallons of fryer oil to use for quenching. Does make you hungry for fries though. -

That'll be a great space for hammer and tool making. What are your (current) plans for the floor? DIrt? concrete? I'm setting up a similar sized space (8x16) to replace the leaky covered patio I work on, figuring out drainage in the new space. Looking forward to seeing your new shop!

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

My cast iron forge table is under a leaky patio roof. During the rain, I have one of those save-your-driveway drip pans, 3 foot by 4 foot that covers the whole of the forge and overhangs quite a bit. Keeps everything dry. Tarps over the tool tables, lots of long, heavy bars to hold everything down. working on a watertight structure, having to figure out drainage in that part of the yard before erecting anything though. -

Nice little shed you have there! I would also considering cutting a hole in the floor, once you decide on an anvil location that works for you. In the meantime, you might consider stacking up some cribbing under the floor where you're anvil is for the moment. It looks like access underneath is not a real problem. if one of the pier blocks is convenient to back up the anvil stand, start with that and see if its absorbs enough shock, not a big fan of cement for anvil support, but if its what you have.....

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

I like your rail anvil set up! -

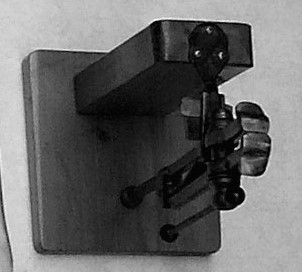

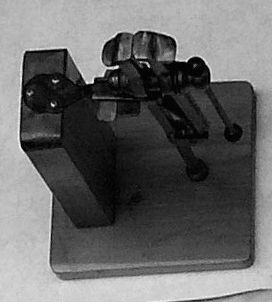

First garage sale in I don't know how long on Saturday. Picked up this little bit of kit. I'm assuming this is one end of a machinist clamp I have vague memories of seeing.

-

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

titanium! those must be wonderfully light! -

What did you do in the shop today?

Michael replied to Mark Ling's topic in Blacksmithing, General Discussion

Went through all the tongs on the rack (and the pile under the rack) and sorted out almost a dozen to be gifted to a good friend who opened their blacksmith shop about 6 months ago. A lot of those were bigger than what I normally used day to day, but she's doing gates, railing and running a 25 ton press with just a couple small pair of bolt tongs The gifted pile, most from an estate sale 3+ years ago, $5/pair (couldn't just leave them there!) Top down view of the now roomy tong rack, 30 sets or so should be plenty! -

Da Vinci helve hammer

Michael replied to Apacheforge's topic in Power Hammers, Treadle Hammers, Olivers

there's an Italian paper model artist (Paperpino) who has devised plans for a sand powered paper model of Da Vinci's hammer. A free download though it is a rather involved paper model. He has a handcranked version as well. This model would last all of about 10 seconds in a a shop setting, being cardstock and all. Considering a hard material version at some still toy sized scale. No affilliation etc. I've built a half dozen of the paper models from the free .pdf downloads.