Apacheforge

Members-

Posts

28 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I remember the 1970s series “All Creatures Great and Small” About a country vet in 1930s Northern England. In several episodes the actor was shown with his bare arm shoulder deep in the south end of a north facing cow, with no glove at all. Big Ewww.

-

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

I had a recliner once. Don’t know who got the most use out of it. Seemed the moment i found time to set in it and git my feet up, the wife of that era would just remember something that needed doing right now ! Come back and find either the cats or the dog, or all cozied up on it. Obviously no good to me. I think the sight of me relaxing just annoyed that wife so much she just had to come up with something to keep me out of it. I lived just on the outskirts of Prescott Arizona at the time. I hauled it out to the woods and built a blind around it and used it for bagging squirrels, rabbits and doves with an old Stevens .22 short using bb caps. Cheese unt krakers on a raft! Was i ever that young! Hard to believe that was nearly 50 years ago! -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

That cannon is in fact a US army breech loading mortar from 1900. As for barrel availability, in the 1970s through to 1990s demiled artillery was an easy find at scrapyards near military bases and army surplus stores. Mostly obsolete AA barrels in 40mm, but other stuff too. All mostly ww2 and Korean war scrap. I had a eight foot long section of 3 inch ordnance rifle barrel that i was making into a full scale civil war Whitworth gun. I traded an old Springfield 03-A3 for it. These days, i see 20mm vulcan barrels and not much else. Its mostly because missiles and rockets have replaced most artillery. -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

So now. The trunnions are now in place. The receiver to barrel is a shrink fit, so i heated the receiver to 400 degrees F and checked the id until it read .005 over the barrel’s od. Picked it up by the trunnions and it slid onto the barrel and seated perfectly. The barrel was stepped and the receiver turned to match, so when fitted, locked into place. -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

The gun has been tested in a oak deck-carriage with a two pound powder charge and a ten pound steel projectile. Fired into a hill a thousand yards away. We located the impact hole but never recovered the projectile. Free recoil was about 15 feet. What i call Fun-loads involve a soup can filled with concrete with a wooden plug at the can’s opening. This is now the base of the projectile. At ignition the plug is forced deeper into the can, which expands the rim to engage the rifling. Uses about 5 oz. of powder. At 300 yard targets, its fairly accurate. And recoil is only 24 inches. On the pivot mount, the gun’s mass and the restraining tackle, along with the coil spring, handles the recoil easily. The barrel is a cut off section of a naval 3in.- 50 deck gun. The breech is a nickel steel alloy and they screwed together on a 4tpi whitworth thread. I built the barrel 25 years ago, but built the mount just nine months ago. -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

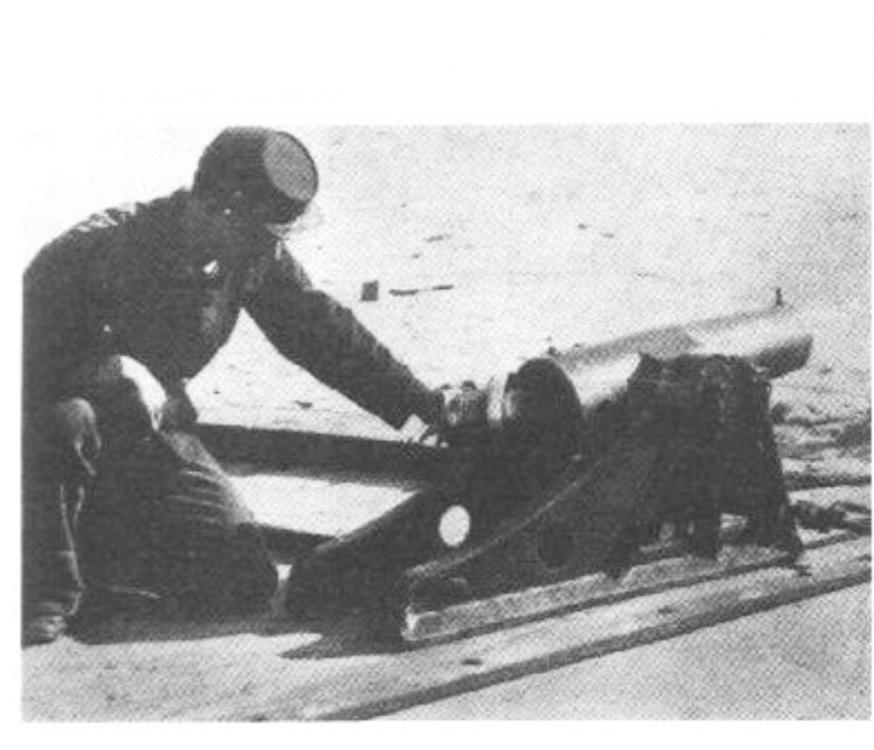

Here is my 3 inch rifled howitzer on a pivot mount. I have a coastal battery of six artillery pieces that overlooks a tiny harbor here on Puget Sound. Too much fun. There is a gun range 50 miles from me, but there is a lot of public land between here and there, so i use public land. -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

Here is the receiver being set up for locating the trunnions. Counter bores were added and the trunnions had a stub turned at the base to fit the counter bore. I then Tig welded them in place with nice big and deep filets. I then bored and turned some solid 4130 bar into collars that will be coped for a nice fit and then welded in place. -

1718 Puckle Gun redux

Apacheforge replied to Apacheforge's topic in Gunsmithing, Muskets, Flintlocks etc

A few friends of mine have purchased little Krupp 50mm pack howitzers that were found in a warehouse in Thailand. Cute and deadly from around 1900. At the time my friends bought them, those guns sold for $25,000. Now you can expect to pay $75,000. Heres a pic. -

Show me your anvil stands

Apacheforge replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

About 6 years ago i was outfitting my 120 year old sailing ship with a selection of tools to repair the old girl while cruising. Part of the outfit included a small gas forge and was on the lookout for an anvil, when, glory be! I found one at a flea market. A Trenton 120# for sixty xxxxxxx dollars!! its been in storage for 3 years and i retrieved it last year. I had some stubs of black locust, about 6x8x19 inches and lag bolted them together for a nice stump. I have blocks of black locust holding the anvil to the stump. No chain or staples needed. That anvil does not bounce or move. -

Sterling silver candelabra - broken arm

Apacheforge replied to KCaz's topic in Welding/Fab General Discussion

When i was a very young adult i opened my first retail jewelry store/ manufactory. Selling my own custom design work and carrying some other artists hand made silver jewelry. I also had a job shop in the back with a couple of benchworkers cranking out silver jewelry that i was wholesaling. Eventually i began taking in repair work. This shop was located in a very well off to wealthy area, so it was common to have silverware heirlooms brought to me. It was common to get a phone call and be asked as you have done...” its broken, can you fix it?” I needed more information than a phone conversation could provide, i needed to see it. How it was made originally has to be determined and if it is fabricated or cast, or if it is filled or hollow or solid. Also old silver candelabra were often filled with a paste very high in arsenic.... in those days i turned quite a few of these jobs down, however with these new laser welding machines in the jewelry trades, i think such delicate repairs are possible. So find a shop that has a laser welder and you might be successful. -

This is my 1945 Sheldon lathe 11x36. I had to rebuild the qc train, and now runs fine. I designed a horizontal boring system for drilling bores in some solid cast iron cannon barrels i had laying around the shop.

-

So...

are you a big gun doctor? Or a big gundoctor?. I see you are in Nevada so i guess both are possible. I, myself am more the big gun doctor, preferring artillery to small arms

-

Da Vinci helve hammer

Apacheforge replied to Apacheforge's topic in Power Hammers, Treadle Hammers, Olivers

There have been examples cited for just such a spring. Looking at my system, i can see how such a spring can be fitted. I think a greater horse power of motor will be needed to push against the added load. Experimentation will proceed. -

Da Vinci helve hammer

Apacheforge replied to Apacheforge's topic in Power Hammers, Treadle Hammers, Olivers

I found that the rpm of the cam was too high so after some calculations came up with a pulley combination that gave me about 80 strokes a minute. The cam was made from two inch thick sections of fir sandwiched between plywood. I notice friction wear was occurring and added a 2 inch wide strip of heavy gauge sheet brass as a bearing surface. While yes, i could have built a much refined version, i just wanted to bodger up a machine from material laying around my boatshed. Built mostly for fun as i really don’t have a need for this to make a living. It is a fun toy to make other fun toys.