-

Posts

828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dogsoldat

-

Awesome job on the feet they just have that real raptor feel to them. The shape and hook of the claws makes me think of the stuffed great horned owl at mom and dads. Same deadly wickedness.

- 32 replies

-

- scrapartoz

- wedge tail eagle

-

(and 1 more)

Tagged with:

-

thanks guys was curious. had googled for it but nothing had come up and an inquiring mind wanted to know if it was my computer or something else.

-

Can anyone else get onto the Anvilfire page? Keeps giving me a this page cannot be displayed.

-

yep that would be correct

-

The hold down has proven itself already, used it to hold the top tools down while punching the holes. Been a real treat to have wish I had found the right sized stock sooner. I've seen a video of an old gentleman carving the pliers may have even been posted on IFI. The springs are scary strong. quite the job cutting them down so I could extract them safely from the old track frame.

-

Had a little time to play today. Cranked the forge up way hot and gave a few handled tools a try and a new hold down from an old coil spring. Been thinking of making a turning wrench the way Mark Aspery does in his book. Needed a fullering tool for that so dug out a few bits of spring from the D-8's track tensioner springs. The piece in the chop saw will be a set hammer, if I remember right the material for it use to be a torque arm of one of the logging trucks. Was a little bored the other afternoon so I whittled up a set of mini tongs out of a small willow branch. And from a week or two back brother in law was looing for a solution for his kebab skewers. Beat out a set of duck bill tongs from some 1/2"sq stock. One day soon will have to get out and visit so he can give them a try.

-

not sure what I think about milling the face. lost a bunch of good life there. a possible thought would be to mill the far edge at an angle similar the Austrian anvils of course no more material removed than absolutely necessary. would think being in a maintenance shop you could get the required Stoody rod or equivalent and build that edge up. (the Gunther method)

-

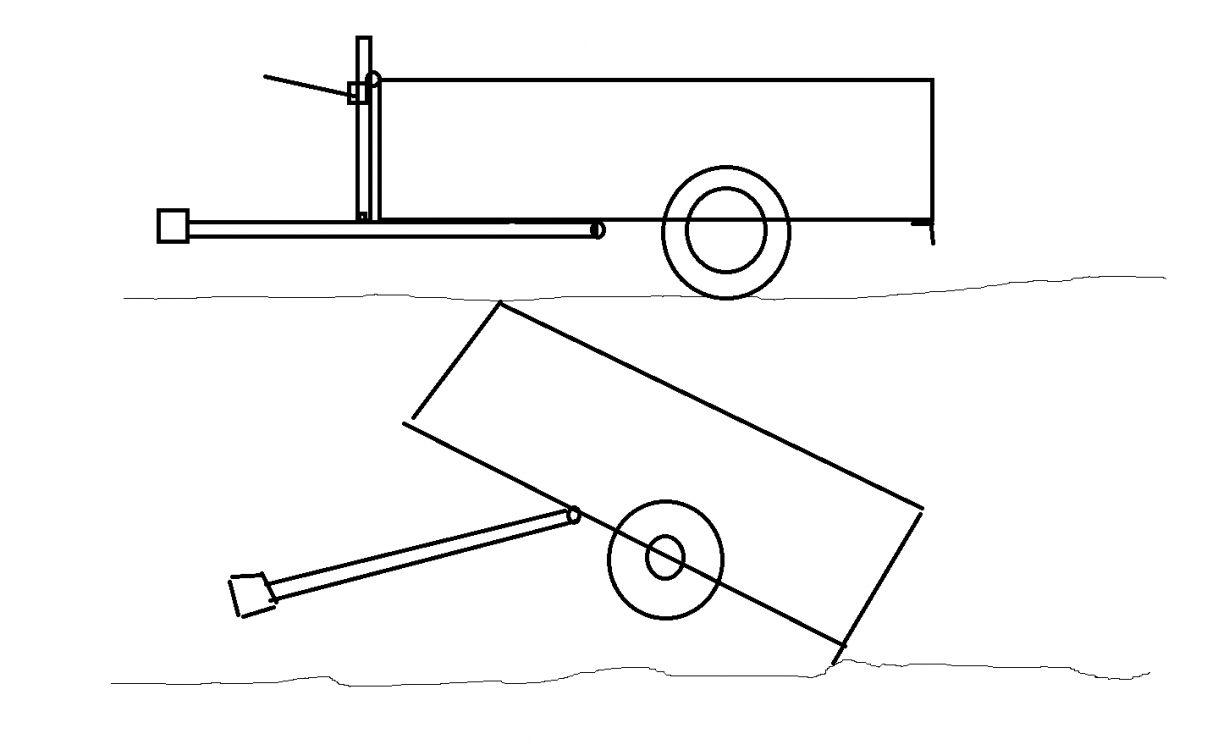

I'll try to grab a few pics tomorrow after work. I made my little 4x8' utility trailer so it dumps. In the front is a hook on the upper edge of the box and a tab on the tongue. I have an old cheapy bumper jack that fits in and you lift it up til the bumper gets a good bite in the ground and back into it to lift it higher. Has worked well behind my truck. Lost count of how many loads of dirt have gone out from under the house. Have a tab on the tongue that bolt goes thru to keep it together when your just dragging it around. Have to figure out what 2x4x8' of fist sized rocks and dirt actually weighs one day and figure out how overloaded the poor trailer has been.

-

Wife has been watching a few local buy and sell pages on facebook. well she found an 8x8' shed for cheap. $50 and an hour later had it home. Think she was thinking a bigger chicken coop... I get it for my stuff though set of old camper jacks, pry bar and block onto to the little trailer it went. Tight squeeze between the corner of the house and the trees. Only one branch ended up in the way. One little adjustment because of a dip next to the tree. Not cool blacksmithing tools but it's the next best thing a place to store them... The neighbours boy helped me drag it into place with the chain block tonight. He had fun! Just need to build a few shelves down the one side and it'll be nicely setup.

-

55 gallon drums. What can you make from them?

Dogsoldat replied to Glenn's topic in Blacksmithing, General Discussion

So If I were south of the Equator di I have to make the cut outs face the other way Coriolis effect and all. -

So is that textured between dies of some sort. and if so be curious to se the tooling to do it.

-

Small pick axe against minecraft

Dogsoldat replied to Momatt's topic in Axes, Hatchets, Hawks, Choppers, etc

Like the pick! Better come over and hang out with the wife, she's not into Minecraft. Me and the girls and the neighbours boy on the other hand... -

Nothing bare bones about that! Looks like something I'd love to have on my belt when out in the woods.

-

55 gallon drums. What can you make from them?

Dogsoldat replied to Glenn's topic in Blacksmithing, General Discussion

Makes nice sheet metal for roses. Made a 45 gal drum forge and had the disk off the bottom to play with, Was something else but it eludes me right now. -

Nice work! Bet he'll be pleased with it.

-

Could be a mortising chisel for timber framed buildings though it does look to have been hit hard and pretty blunt on the one end

-

-

Well I installed the footrest today. Bald as a sheared sheep to... Feels good to have short hair again even if it ended up a touch on the short side... Guess that's why it's called Shorty's Barber Shop. So heres a couple of pics for those interested. And on the shelves by the mirror is his growing collection of clippers razors other various odds and ends. Should have taken a picture of it but he had a wooden box that can be dated to 1812 and when the wooden divider between the inkwell and other spot is lifted it opens up a panel that hides 3 little drawers.

-

Wow! that turned out NICE! I find the shape and flow of it very pleasing. I think the corners look good. Don't want them to sharp or it won't be good in the hand. Definitely adding a pic of this to my knives that I like folder...

-

Just under the freeshipping thing on the right is a continue box . Takes you right to the item. I bet the screw from the trailer jack would work beautifully. Something else to keep my eyes open for in my travels.

-

Was looking at something or other on Lee Valley's site and came across the Kits for woodworking bench vises. http://www.leevalley.com/en/wood/page.aspx?p=72652&cat=51&ap=1 I didn't see a spec on screw dia but they are a double lead with 1/2' pitch. Not cheap by any stretch but may be a possibility if someones in a pinch to get a screw in a post vise.

-

project I'm working on (hobby or jewlers anvil)

Dogsoldat replied to Damion78's topic in Anvils, Swage Blocks, and Mandrels

Nice work, heres the one I made out of a chunk of D-8 cutting edge. The stem is 1" square A36 and the shank is 3/4 sq to fit my small anvil. Also made a stand alone base for it out of a block of wood and a bit of 1/4 or 3/8" plate for a stake holder. Been really handy for making small copper roses. -

couldn't just say all that blacks stuff was for a little weight on the drive axles. better winter traction you know. gotta be safe :) and all. and well if a little falls off on the way up... I'm sure some one would have a loader to top of the weight somewhere in between

-

Ah ok! that all makes sense. Thanks for the info.

-

Looks like a very nice tool. Just one small question, shouldn't the bevel be on the bottom of the blade, the handle side? googled adze's guess there are a fair number out there with the bevel on top. Not sure what the dis/advantages are though for one way or the other.