-

Posts

828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dogsoldat

-

why did my angle grinder stop working

Dogsoldat replied to GhostTownForge's topic in Grinders, Sanders, etc

I've had switches and brushes fail. Also something to check is if the wire in the cord is broken. Most likely spot is right where it is pinched entering the body of the grinder. -

Casting a Gingery Lathe

Dogsoldat replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

Any heavy duty ruck shops nearby? A lot of Aluminum in a 22-24" semi rim Just a matter of breaking it up with sawsall or something -

Mass production of armour.

Dogsoldat replied to FlatLiner's topic in Blacksmithing, General Discussion

Thanks for posting, been time well spent watching. -

Wife’s aunt sent me a picture of this thinking it is blacksmith related. Looks to be a set of saws and jewelry files. Any seen or used something like it.

-

What did you do in the shop today?

Dogsoldat replied to Mark Ling's topic in Blacksmithing, General Discussion

Started on a hammer yesterday. Heat treated today. A bit soft in the center of the face but edges hardened nicely. Peen skates agile really good. Back out and make a handle after a quick bite. Started out as a 5” piece of S-cam weighs right around 2.25 pounds by the fish scale. -

Anyone know what these tongs may have been used for? They are a little tweaked and been made or fixed with an arc welder.

-

Followed a few rabbit holes on Bronze Age casting and such. Socketed axes, swords Roman plumbata… This article discusses wear marks on socketed hammers. Something that stood out was a bronze hammer reworking a bronze axe cutting edge was more of a planishing action. Which likely makes for nicely work hardened cutting edge. https://exarc.net/ark:/88735/10244

-

Went down a rabbit hole or two chasing interesting links. Went from Russian machinist making a 10 start left and right hand thread bolt and nuts, to really interesting stuff. Nearly have the 10 part series watched. Episode #3 he makes his file cutting chisels and files. #4 he gets into case hardening. There is bronze casting, experiments for a historical version of dyechem ? for layout, some techniques for soldering...

-

Wonder how close the 'Stink Fish' would be to Roman Garum

-

Thanks for the info guys. The video was rather educational Frosty. Learn something new

-

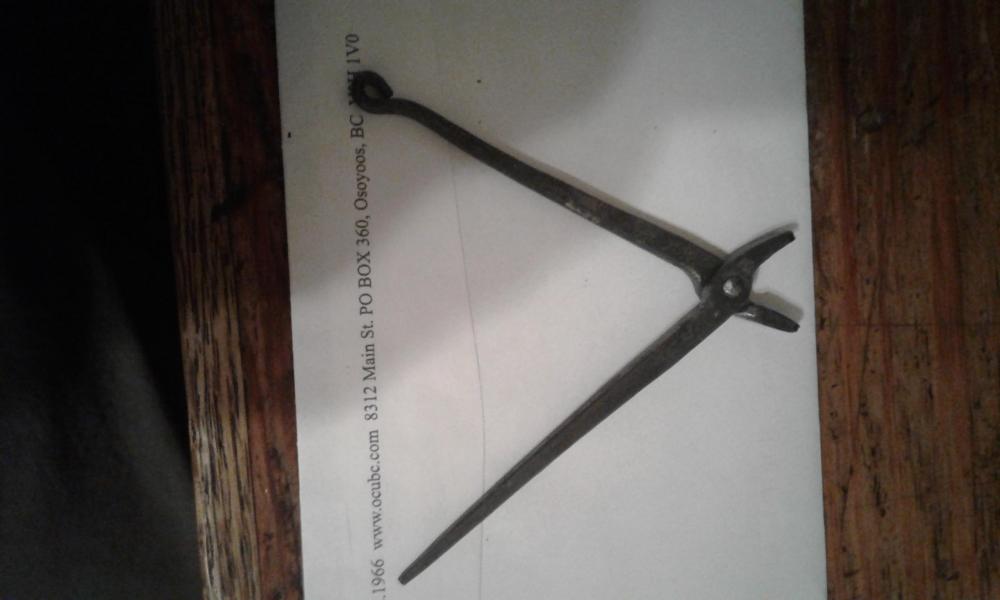

A friend on FaceBook post a picture of this tool asking if anyone knew what it was. I've never seen anything quite like it before.

-

Never figured it would be the most efficient way to cast but they do seem to be rather good at what they do. I've done just enough casting to know there are better starting materials to work with. At any rate thanks for the insight into the moulds Frosty.

-

Wife sent me a video of casting large pots from recycled cans. They seem to have it down to a science. The sprues are just enough to suck down flat when they chill. Any ideas on what the moulds might be made of. Must have a fair bit of preheat in the mould to get the even fill.

-

any logging trucks in your area, ask for the ends off a broken wrapper. usually 5/16 or slightly lighter chain maybe 3' long on the end of a cable for wrapping a load of logs.

-

Antique arms shop, New Orleans Photo Heavy

Dogsoldat replied to 671jungle's topic in Gunsmithing, Muskets, Flintlocks etc

Had my hands on a matched pair of 32 cal pepper boxes very similar to that at one time. Great aunts friend had a box full of assorted antique pistols her husband had collected in eastern Canada. Was lucky enough to poke through it and take a look. There was an Arabian scimitar as well. Wicked sharp and curved. wish I had my camera then... -

scythe sharpening stake maybe? drive it into anything convenient next to the field. Interesting at any rate

-

What did you do in the shop today?

Dogsoldat replied to Mark Ling's topic in Blacksmithing, General Discussion

Start of another knife and a dragon fly for a friend. Only a little propane left in the tank, just enough for one last project, whipped off a set of tongs. -

What did you do in the shop today?

Dogsoldat replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished up my second Serbian chefs knife today. Piece of 5160 and mahogany, maybe, for the scales. Wood came from a box full of scraps of a recently passed friend. Came out much lighter than the first which has birch scales. First one has already gone to it's new home and second soon to follow. -

This anvil had crossed my facebook feed. Hadn't seen this particular makers mark before. anyone know what it might be?

-

Thanks guys. tobacco container it is.

-

I've seen this can around before. I'm sure it was my great grandfathers, but not positive. Any idea on when and a what it was used for? Only writing on it is 'patent applied' stamped on the bottom. Mom had it stashed in a corner and came across it again.

-

Would it be something a steel mill may still have in circulation? Maybe a call or two to maintenance might get you a lucky break

-

Thanks for the quick help. She's living in Kelowna, lots of things grow well in the Okanagan