-

Posts

378 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://hallironworks.blogspot.com

Profile Information

-

Gender

Male

-

Location

Evansville, IN, US

Recent Profile Visitors

4,972 profile views

-

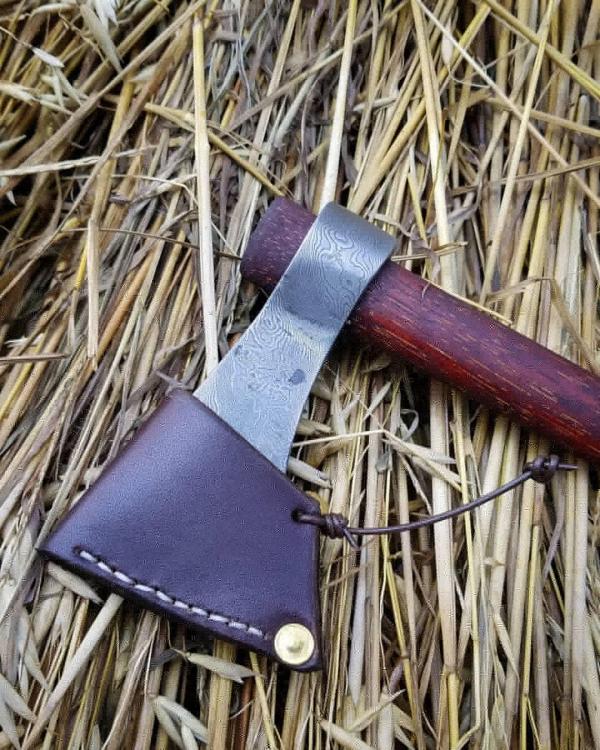

Forged this quite somentime ago but finally finished. Not big on doing Damascus, but sometimes I feel lucky! 130 layer, hickory handle. .5lb, 2 inch but, 4 inch head. Might keep it!

-

Benton Frisse changed their profile photo

-

That is a beautiful axe. Excellent work!

-

Hi Stephen, if you still havent had much luck on this, I would urge you to check out Axe Junkies on Facebook. 30,000 members that are geared more towards the vintage axe restoration and collection ball game. Lots of knowledge on there as well.

- 4 replies

-

- axe

- cast steel

-

(and 1 more)

Tagged with:

-

Thank you everyone for your kind words! I sincerely appreciate every single one. It has been quite the journey but it's only begun. I've decided to move to 1084 from 5160 because of how nicely it heat treats, forge welds, and has a great edge retention for hawks and small camp hatchets. The handles, I'm sourcing my ash from a local joint here in SW Indiana. Longer handles indont carve, but anything under about 20 inches i typically do. I can score 5/4 straight grain ash lumber for pretty cheap. Otherwise, a handle any bigger takes me longer to carve than it does to forge and finish the axe. I really, really like elm. It's my favorite to carve and hang axes on. Not as tough as ash or hickory but it performs well. Should be ordering my motor and pump next week for our 25t press, and then the real fun begins. I've done some heat treat testing of 4140 from tool steel service of California, excellent stuff. I'm really impressed with how it has performed as an axe. Super tough, stays sharp. Having the hard poll is nice, too. Punching eyes, for my personal preference, makes a bit cleaner lines than I can do by folding or doing the asymmetrical weld style. And it also makes a monster axe.

-

Hey Folks! It's been quite some time since I've posted. Just thought I'd share a few goodies from recent orders. The snowy camp axe is mild with 5160 bit, the last of my axes with 5160. It is also a hand-carved ash handle. The camp axe i'm holding is with a 1084 bit, and the long scandi axe, it's smaller hudson bay-ish partner are 4140. The 4140 axes are punched and drifted... I'm not a fan of doing this solo so we're building a 25t C frame press from Batson's book. Pretty excited to have it finished and start punching, drifting, and forging axes! The hawks are mild and 1084. I love 1084... it sticks SO nicely to A36. Cheers!

-

First go at an axe

Benton Frisse replied to BeaverNZ's topic in Axes, Hatchets, Hawks, Choppers, etc

Good clean eye punch and drift. Clean 'er up on the grinder and show us how it looks on a handle. Great work! -

I thought the same! I was like "Man, this is like a damascus version of the Daedric Dagger!" Hadara, fantastic work!

-

True works of art. I hope that one day my work can look a fraction as nice as your work, Jim!

-

Jim, this is beautiful! Stunning pattern and excellent execution of blended styles that normally wouldn't play well together.

-

Mean Little Sucker tanto, bushcraft knife, plus carry pics

Benton Frisse replied to Stormcrow's topic in Knife Making

James, it's so awesome to see people rocking your gear with such pride. #snackbreak -

52100 & W2 damascus skinner. Work in progress

Benton Frisse replied to Jclonts82's topic in Knife Making

Excellent work, can't wait to see the finished product! -

Thank you, Owen! One day!

-

Forging a "Type D" Inspired Axe.

Benton Frisse replied to Matthew Paul's topic in Axes, Hatchets, Hawks, Choppers, etc

FanTASTIC work, MP! -

Sandwich HC wagon tire, 15n20, 5160, wrought iron Hunter

Benton Frisse replied to jlpservicesinc's topic in Knife Making

Killin' it! Awesome stuff!