-

Posts

533 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by nuge

-

Great article from the BBC has a bit on Jake. http://www.bbc.com/news/in-pictures-35531727

-

pine bark for fuel?

nuge replied to Jack Underwood's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

The Mexican coppersmiths in Michoacan use pine bark to anneal their pots. Makes sense given the surrounding flora and industry. -

Good luck Ian, you'll back back at it before you know it. Take it easy....

-

-

I also wear gloves almost all the time. I used to get such bad cracks in my skin but when I stared to be diligent about always gloving up all that went away. I can remember what is hot.

-

If you'll be doing any grinding, that is.

-

Don't forget about your lungs. My favorite respirator ever. http://www.hartvilletool.com/product/1272/respirators

-

Sculpt nouveau makes a nice solution called black magic. Any patina you use will react much better if you sandblast or soak in vinegar for awhile.

-

A Hossfeld Bender would do those sections easy, cold. And so much more. Spendy to get going but sometimes you see them on craigslist.

-

The decorations on my hooks are done with dies. Yes, I make them. Its a really attractive technique because typically surface embellishment is done directly into the work piece like chiseling a vein or texturing with a ballpien. With die work you get the opposite, things pop out at you and some fun stuff can happen. And it's way less common making it unique and visually valuable. I also really like the paw print hook.

-

-

Such a powerful thing to make, a little key chain trinket, charm, talisman. Whatever you wanna call it, a little bit of the smith traveling around the world. Here's one I built for my wife to keep her safe on the drive to town.

-

Dems nice ones. What does the mounting hardware look like? And really nice pics, I bet you'd get some bites on etsy and the like with that photography.

-

Universal Radial Power Hammer

nuge replied to Jim Deering's topic in Power Hammers, Treadle Hammers, Olivers

What makes this hammer "radial"? -

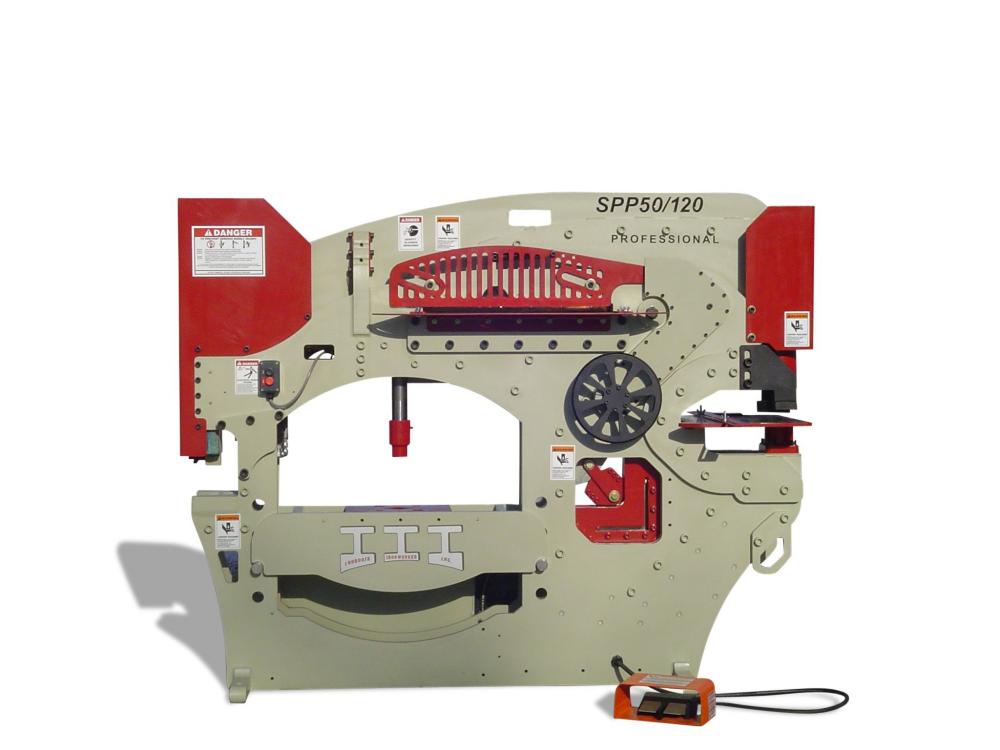

In my opinion there are not many tools that can enhance a general metal shop like an ironworker. They buy you so much time and open up such a larger range of work, be it bigger railing jobs or more widgets, you will wonder how you made it without. What this translates to is way more income, provided you can hustle up the work. One of my favorite Nakedanvil analogies was something like "you see a lot of dudes driving around in big dumb $45,000 trucks lamenting the price tag on a $15,000 ironworker". Which one can actually make you money? Thinking about it this way, the price tag seems more than fair. sexy hunk pic---

-

I would go for the p6 for sure. It's not like anything is heavy. Think of it sort of like your hand hammer, it's a machine to transmit your power into the workpiece. Only you can use way more of your body and not worry about any sort of precision and the machine is incredibly efficient. If it happens to tire you out you rest. I don't think mine ever has. Bigger is better. as to the problem with the handle ergonomics, check the pic...

-

Check out Iroquois Ironworkers. They feature an integrated h-frame press bed. This, coupled with two stage hydraulics make it a really useful press in forging, and fabbing, steel. They are US made in South Dakota. I have the mid range sp 40/75 model and it's great. http://www.iroquoisiron.com/

-

I use two big Thumler vibratory machines and tumble dry and have used a variety of media. The two I like best are carbon steel ballcones and porcelain balls. I like the finish of the steel a bit better and the ease of cleanup of the ceramic is nice as I have to wash (simply running a wet cycle or two with some simple green and water) and rinse after five to six cycles. It's not a tough process and I very much prefer the work to my alternative finish which is an angle grinder mounted wire brush. Cleaning the carbon steel is just more finicky trying to avoid rust. Working this system in the winter gets harder as I don't always have the heated space ( tumbling requires some room) and water supply readily available so I tend to finish in large batches if possible. I am always looking for some stainless media but that stuff is expensive at retail. I have heard that in barrel type tumblers you can suck out a lot of the scale dust with a vacuum while the machine is running and the particles are airborne. Seems like the best way if it works.

-

How can you police a discussion effectively after this statement? Doesn't make any sense at all. Love, not fear, is the only way we all progress.

-

I am with Alan in that in that I find the trajectory and current location of this thread astonishing and a bit frightening. Good luck with your family.

-

Induction forge on 3 phase converter?

nuge replied to Judson Yaggy's topic in Induction Heating, Oil forges, etc

There is some good info on this archived over on the NWBA forum. Grant ran his on a rotary, i believe it was a 30KW machine. You would surely need a larger phase converter, like 20 hp or more to run the 25 KW. Honestly I would say get the single phase unit because you are wasting time without it, two years is too long to wait. -

Nice tool. I like the pullmax too, fun machines.

-

It's all fun until you have to break those corners. No way around that process except your arm, huh?

-

Retaining wall made of discarded guard rail. Every second or third section has a deadman nailed into the soil with three 4' spikes. Its about 5 feet tall at the highest point.