-

Posts

642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by j.w.s.

-

Here's a piece I did a few year ago.. you can achieve the look you want but not the way you think. J

- 6 replies

-

- forge

- forge welding

-

(and 2 more)

Tagged with:

-

I can always ask him - I saved his number just in case. J

-

-

Not sure about Peters Valley's classes although I've had a lot of students who've taken their classes before mine. I'm adding an axe class to my schedule but not until March 2016. J

-

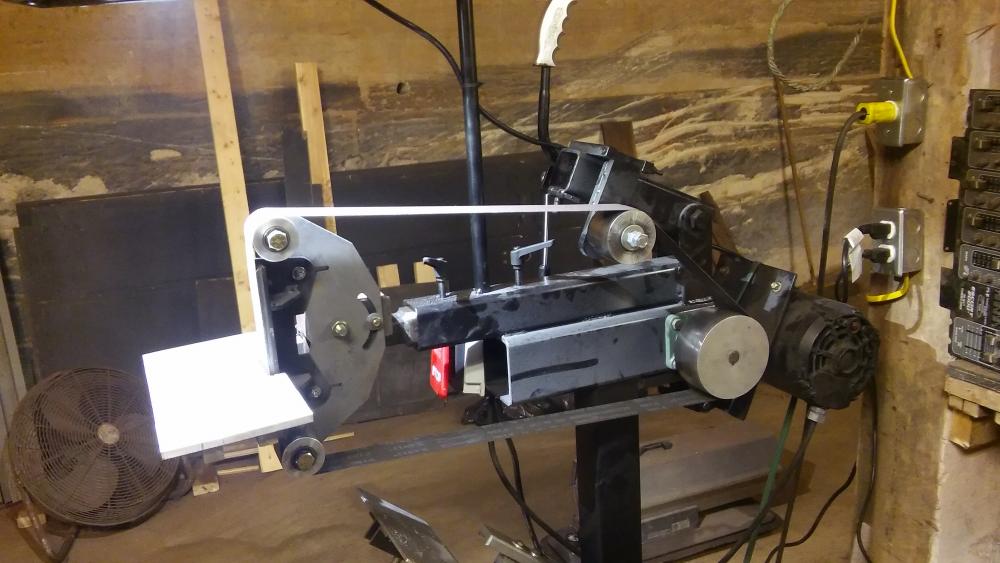

On a whim I searched the local craiglist and came across this gem. 240v 3hp variable speed 2x72 with a handy led work lamp. Weighs in about 250lbs if I were to vernture a guess. Guy did a nice job for a home built, few interchangeable wheels and platens for it as well. Didn't like his 10" wheel construction plus I've got an 8" on the other grinder. Drove it away for a song, basically just paid his parts bill. Unloaded it, now off to buy what I need for running a dedicated outlet. Just goes to show, sometimes craigslist is useful. J

-

Welcome to the black hole of the country! After a few months you'll find yourself getting drawn back here time and time again.. I've had friends that have moved all around this great country of ours only to find themselves back here again years later. Maybe it's the fresh produce, maybe it's the fact that there's always work to be done, maybe our laid back pace of life or even the smell of cow manure - who knows?! Lol Glad to have you, it'll be some interesting times to say the least - looking forward to it! J

-

This ones together from the inside out using those spiked joint plates. J

-

Around here it's $1/lb. J

-

-

They look very much like the "1095" and "15N20" billets being mass produced in Pakistan.. I had someone give me one not that long ago and it's all delamination headaches under the hammer.. If thats what they are, then they're pretty enough for guards, bolsters and maybe even a little stock removal. J

- 9 replies

-

- damascus

- damascus pattern

-

(and 1 more)

Tagged with:

-

I'm heating it in my largest forge with an hour soak at 1750F - that's the most difficult part of the process.. Well, that and moving an 85lb block of steel at that temp.. Next is air cooling. Rate should be constant, so the shop fans will be pointed at it. Since I'm not heating the entire block to 1750F, only the first 0.5", the rest of the mass should also help with an even draw of temperature. I'm looking at about 12-17 hours then in the oven at around 500F for stress relief and tempering. I don't have the capability to cryo treat it, but that's not what I'm looking for in this tool. I'll be happy with around 54-58R. J Oh and A2 can also be oil hardened.. But why complicate it? Lol

-

Just a quick run of it this morning.. Seems to be working fine. This was just a scrap end of a san mai billet I had lying around the shop.. Drew it out from 4" to 6.5". My only complaint is that the stand tends to rotate slightly but that's easily fixed with an anchor bolt or two. J

-

I had a choice today between a nice Hay Buden for $440 or a block of A2 for $85.. Had the cash in my pocket and chose to get creative and save a few dollars.. I've already got a Soderfors in the shop, a Fisher and a nice stake anvil.. This just seemed right to me. J

-

Can't hit an ugly anvil.. Lol.. Plus the better it looks the more it adds to the illusion that it's meant to be what it is. J

-

I just cut the 4x4s to receive the 5x5 block and to keep it at the height I wanted. The anvil has about 0.1875" play all around and just shimmer snug with some scrap pine. If I had to guess on the weight I'd say it's about 150lbs total. J

-

Here was today's project - drawing inspiration from the floor based Japanese anvils. Still need to dress up the edges and harden the face, but the hard part is done. I took a 5"x5"x11" block of A2 (85lbs) and built this stand around it. I just wanted an extra anvil around the shop for teaching classes plus, a nice object lesson for anyone who visits the shop and brings up the inevitable "where to find an anvil" conversation. The primary point of this is that you don't need a horn or a heel to have something that's effective - and you don't need to spend an arm and a leg.. My total cost was around $105 for everything including the new box of screws I had to buy because I couldn't find the one at the shop. J

-

I buy cases and cases of 2x72's from them.. doesn't hurt that it's only a little over half an hour drive either to just pick them up. They assemble all the belts on site and can do custom belts as well. I also grab a box every few years of their scraps by the pound.. all assorted grits (although they ask me what range I'm looking for) - I get something like 15lbs of paper for $15.. the other nice part about just going in person is the stuff they don't advertise, my last trip I got 50 sheets of 1200 grit for $5. The owner is awesome and will gladly search her sources for hard to find abrasives that they don't make as well,. J

-

Is anyone selling these burners in the states? -J

-

the only time i turn it i when welding the ends. I twist the rest tight and weld the blade solid followed by the tang if applicable. J

-

There's a happy medium when twisting, but if it's loosening up then your weld on the billet wasn't good. In class I always point out the audible difference once that weld sets, I don't really know how to describe it here though.. but at welding temp when you start it should be sort of a "thunk - thunk -tonk." Perhaps I should have demonstrated while you guys were here - only takes me 25 minutes from start to blade, but I've kinda got a system down. In my cable class I typically expect about an hour and a half to be eaten up by forging. J

-

Well, actually that rope was brand new from MacWhyte, you just didn't pay attention to the spool I have of it near my coal bin. I don't like repurposed cable just like I don't like repurposed springs - never know what the previous life had it doing. So, did you first forge weld your ends, then tighten the twist? While I get some reduction in size after welding I get a quite solid non-"squishy" steel. J

-

Thatd be Tuesday's, Friday's and Saturday's - fine with me.. J

-

Still scratching my head over that one.. see, I even got a text message the night before asking what kind of beer I like - my answer "just about anything but wheat beer". Now one might be inclined to believe that such a question implies that beer is being brought, when in fact I think it was just a way for Marcy and Nick to psychoanalyze me or something because there was definitely no beer in tow. Burn my coal, take my steel, complain about the lack of pie and leave me crying into a nonexistent beer bottle. Now that we've hijacked the new kids thread I'll bring it back around: IWF, the moral of the story is "beer is the price of admission to my shop" (although obviously I take the uncouth individuals who don't bring beer into the shop as well) and yes, there is at least one smith on here from the Lancaster area, my shop is in Manheim. J

-

how come you didn't bring beer? J

-

We have pie?! J