-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

New England Blacksmiths Meet June 2017

jlpservicesinc replied to jlpservicesinc's topic in Events, Hammer ins, Where to meet

That is a traditional style hasp.. -

Yes, it's a little extreme but I got tired of doing demo's in the old rig..Figured it was time for an upgrade.. Here's the old trailer.. Of course the old trailer was very old (built 2004 IIRC) though I did a rehab on it in 2014 keeping the original roof.. 2013 had to be careful where you stepped or you might go through the floor.. 2013 was a fun year as on the way home from the demo the rear plywood section that held all the lights was trying to race me home all by itself.

-

New England Blacksmiths Meet June 2017

jlpservicesinc replied to jlpservicesinc's topic in Events, Hammer ins, Where to meet

I used to have that drill.. silent auction or traditional? 2 person team? Ouch? How many people signed up now? -

Here is the complete build.. Anvil is on the ground..

-

Asking for design help for an anvil stand

jlpservicesinc replied to JHCC's topic in Stands for Anvils, Swage Blocks, etc

Nicely executed stand... How did the 3foot win out over the 4foot? Here is the stand for the 368HB.. -

-

wont keep rigid as they are tapered so unless they are going into tapered sockets.. Well you get it. If not supported in more than one place or a tight fit at the receiver.. the finial to shank being a v around a rounded eye will act more like a hinge than a lock.. It needs more support.. Besides that when a door catches wind it will take quite a bit to keep in from pulling or snapping off the screws.. I'm sure just pushing a little bit on the doors would show how the leverage effect would be in full application..

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

Even the junk moves pretty fast.. Only thing that slows it down these days is the price.. I've seen people asking 1000.00 for what I would consider a 100lbs boat anchor...

-

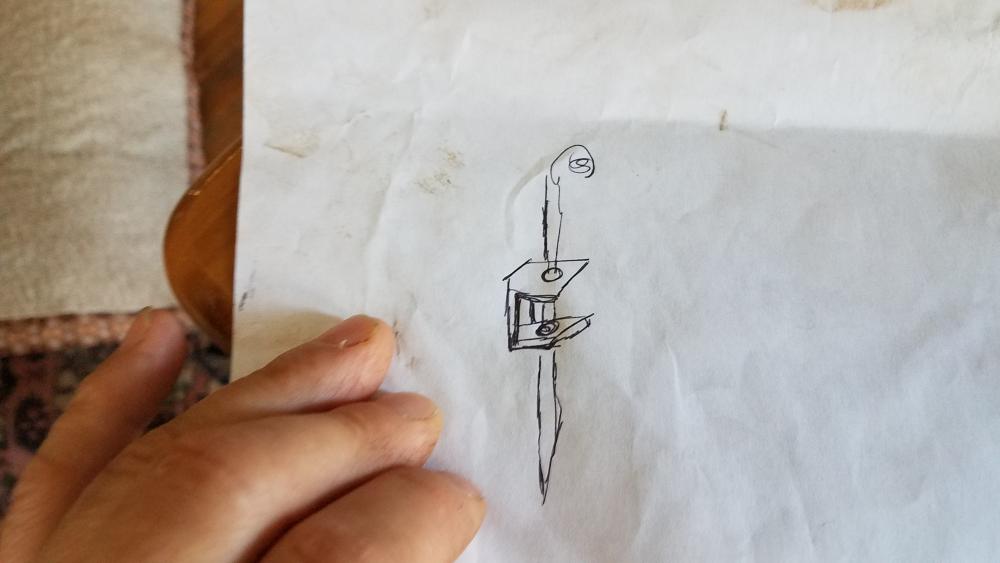

If you use nails be sure to clinch them on the other side of the door.. drill hole undersized.. Make the nails 1/4" longer then all stacked up materials combined.. Make sure the nails are soft.. Here is a simple sketch of the better way to do it or make 2 brackets like you made and make sure the locking rods are long enough.

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

By the way I love seeing you at the anvil in the video.. All the new young blood coming to blacksmithing and having a skill set to boot.. Puts a big smile on my face..

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

Nice work but not quite sure what they are for? If they are to hold doors closed only having one hole will become a problem as the pin will want to twist..

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

Yup beautiful for sure.. Thanks.. How big is the screw? What's the thread count?

-

Sadly I have never tried a Mousehole either.. Trenton(german), PW, HW, Columbian, Vulcan, Eagle, Mankel, Delta Future, NC, My favoritevintage because of how they are made is still HB..

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

spring steel use and cooling?

jlpservicesinc replied to Dan Smillie's topic in Heat Treating, general discussion

http://www.tempil.com/resources/application-charts/ if is in PDF form here.. Sorry but I have found mild steel springs for this type of application unless fairly thick don't hold up with daily use.. Forging one out of 5160 isn't a big deal and it won't need to be hardened or tempered for a good service life..- 39 replies

-

- spring cooling

- leg-vice

-

(and 1 more)

Tagged with:

-

Wow, 8 3/8" thats a heck of a lot of vise.. how long is the handle on that big boy?

-

New England Blacksmiths Meet June 2017

jlpservicesinc replied to jlpservicesinc's topic in Events, Hammer ins, Where to meet

probably not.. I'm not much of a competitor.. Just getting back into forging after a long time off so things are still getting warmed up.. -

New England Blacksmiths Meet June 2017

jlpservicesinc replied to jlpservicesinc's topic in Events, Hammer ins, Where to meet

If you see me introduce yourself.. Name tag will says Jennifer and I'm built like an outhouse.. Not stinky .. just stocky.. -

Ok, what I don't understand, is why use a bottom fuller when doing something liked drawing out a taper in the video??? I still don't see why it is any better. Littleblacksmith This propagation that using the horn is twisting the metal is off the wall.. The twisting is because of un even hammer hits not because of something that needs to be fixed.. It's user error.. Not because a fault with the anvil or horn.. (A great well skilled blacksmith can make greatness on crappy tools) The tools are not the limiting factor.. As pointed out earlier don't limit yourself.. I find that people don't ever master horn drawing techniques.. It a worthy skill.. I'm all done as I sound like I'm harping about it.. I teach people multiple ways of doing things.. it will open doors or ideas when things seem bleak.. Yes, or I should say I have had a 200lbs Myers in the past and once shop is up will come back home.. As the stock gets bigger you need to swing a bigger hammer no matter how small the contact area.. I would imagine as you have gone on your journey you have found that with experience comes greater speed.. Forge welding creates short cuts in so many ways that no matter how you draw it out you can never achieve the same product.. I guess it was different for me in my early years as I was making a living at making custom hardware and the faster I made items the more money I made.. Each item was a custom item as there was no stock list ( Every customer was purchasing custom hardware) I would tell people go to " Early American Wrought iron" Figure out what they wanted and then let me know.. Working this way you figure out as many short cuts to efficiency as one can this involves every aspect of every corner, of the anvil including the feet.. And I do get there is a certain zen like state about drawing out bars.. I remember those days oh so long ago.. Keep up the good work.. I look forwards to seeing more of your items..

- 77 replies

-

- blacksmithing

- hammers

-

(and 2 more)

Tagged with:

-

Are horses left or right footed?

jlpservicesinc replied to Glenn's topic in Farriers and Horse stuff

ditto.. All horse are one sided.. As are people.. On key thing a lot of people forget is.. We influence anything we touch.. Lots of riding horses have problems with their backs or pelvises because the owner does.. It's funny to think we create more problems than solve.. -

Vulcan 150 lb anvil

jlpservicesinc replied to Rookiesmith's topic in Anvils, Swage Blocks, and Mandrels

yes and no.. LOL.. As a beginner there will be a lot of missed swings and each time you ding a face of a great, flat well made anvil you will be thinking Ut oh.. Or worse is with a missed swing and part of the face of the hammer comes off and sticks in your arm, face or eye.. So, I would be a big fan of a well used anvil or an ALO (anvil like object) or an ASO (anvil shaped object).. You only need one good corner to get started.. How old is your son? I started when I was 8 and really a properly sized hammer was the hardest thing to find.. I bought a 2lbs true temper German cross pein hammer and it's still my go to 38 years later.. Anyhow, why back then a 1lbs would have been better.. That and an anvil mounted at the right height.. -

Fleur de lys-critique requested

jlpservicesinc replied to canada goose's topic in Blacksmithing, General Discussion

bless you.. It looks great.. Keep it up.. -

Attention all I.F.I. Tech & Metallurgy fans

jlpservicesinc replied to SLAG's topic in Historical Blades

Pretty neat. I keep saying that 1000 years from now they will be looking into all the dumps for artifacts on how the primitive people lived.. I keep making wrought iron tidbits and throw them in the trash.. -

Yes, very nice work.. Forged and ground? Do you like working with the 80Crv2? Also for the wrapped handles are you using epoxy under the wrap?