-

Posts

385 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Al Stephens

-

Hi VandalEvil, when you have a minuet checkout Athensforge. We meet the 4th Sat. of each month. Come if you can.

-

Alabama Forge Council

Al Stephens replied to Al Stephens's topic in Events, Hammer ins, Where to meet

Correction, Athens Forge always meets on the 4th Sat. of the month. The next meeting will be Sat. Oct. 22, 2016 Sorry. All other info correct. -

Alabama Forge Council

Al Stephens replied to Al Stephens's topic in Events, Hammer ins, Where to meet

The Athens forge a member of the AFC will meet Sat. Oct.29, 2016 at 10AM. The demo will be on 2 dimensional animal heads, and punches to produce them. Iron in the Hat will include a starter set of punches made at the last meeting. Open forge time will follow for AFC members. www.athensforge.com also on Facebook. -

Hi Donniev, Your last photo seems to show a "lump" on the matching surface of the pivot. I have always found that the flatter and smoother I can keep these surfaces, the tighter everything fits together.

-

forging a leaf key fob presentation

Al Stephens replied to Mark Ling's topic in Blacksmithing, General Discussion

EVERYBODY should look at this!!! Very nice presentation, hope you got an "A". The download worked fine. Many of us could/ should do something like this. Many of us have laptops, iPads, that could be used in classrooms, or many places where, "fire" is a bad word. Great Job. -

Feel free to come early and introduce yourself and look around.

-

The Athens Forge, a chapter of the Alabama Forge Council, will meet Sat. Sept. 24, at 10 AM. The demo will be on forging punches to fashion animal heads. Open forge time will follow demo. www.athensforge.com

-

Teaching a total beginner?

Al Stephens replied to Everything Mac's topic in Blacksmithing, General Discussion

Thank you Dick, that is a good idea. I've always used a piece of modeling clay, it can be reused many times, but they could hit the 2x4 harder,..... or miss. I sometimes draw a circle on the anvil face, and try to get the student to do all the forging within the circle. My teaching partner and I had a class yesterday, 8 students, 14 yr. old girl, to a "mature" woman, 6 guy's. Everyone completed the project. I learn something new every class. -

-

Had some "play time" today. Made a couple of new hammers. Hammer heads are forged hex stock. Handles are wood match sticks.

-

Hi Jim, Really like your forge. Would you give us a picture of the spring vise? Did you build it ,or buy it? Al

-

When stamping several names, words, in a given space I also "lay out" from the center letter or space. It has helped me from running out of room, with 2 letters to go!

-

Teaching a total beginner?

Al Stephens replied to Everything Mac's topic in Blacksmithing, General Discussion

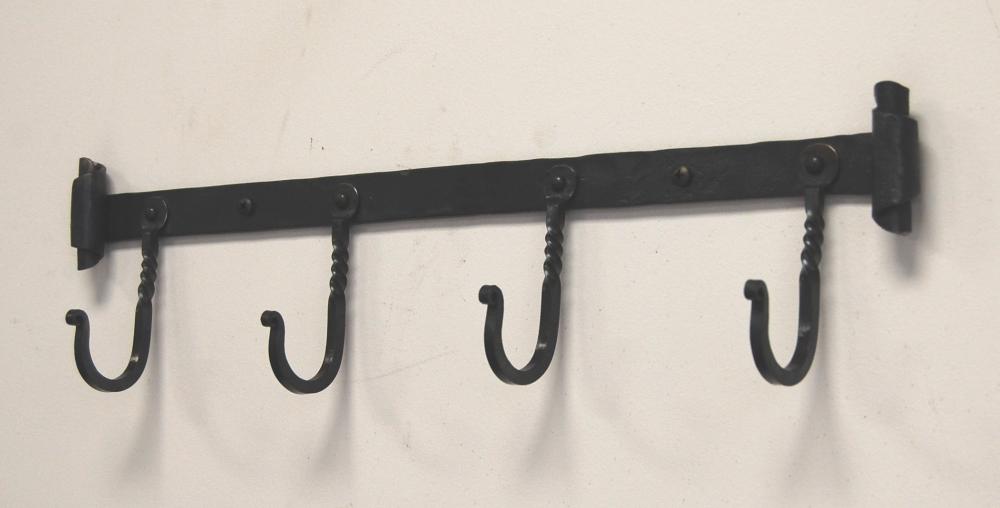

Years ago I came up with a beginners project that would teach a lot of basics, and give the student a usable completed project to take home at the end of the day. I've used this with 10 year old 4-H classes, boy scouts, college adult education classes, with young and old, most of which had never done any forging, and every student has completed it in a day. It's a simple 4 Hook Coat rack, I'll let everybody figure out everything it teaches. -

My main forge area is set up in a circle. Forge, 12 o'clock, Power hammer, 3 o'clock, 4'x 6" work table, 6 o'clock, main anvil, 9' o'clock. Work table with vise, at 10:30. The 4x6 work table base is an old metal office desk with an enlarged steel top. I keep all hammer dies, and hardy tools in the desk drawers, it's also good storage for any high use tool. The gas forge sets on an old roll around tool box, those drawers are also full of, tools, and bend jigs. Large jigs hang on the walls. I try to keep my floor space, trip hazard free.

-

Sat. Aug. 27th 10AM. Steve Williams is coming down from TN. to demo. Not sure what he will be doing.

-

Thomas, you might want to checkout, "Show me your Anvil Stands" here on IFI, lots of good ideas there.

-

Hi Thomas, Athens Forge will meet next on Sat. July 23 at 10 AM. We will be making anvil tools for the AFC tool box to be auctioned off at Tannehill in Sept. Meeting will be at the same location of the Athens State classes. Hope you, and anyone else who wants to come can make it. Contact me if you have any questions.

-

Show me your Bottle Openers!

Al Stephens replied to Arbalist's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

Al Stephens replied to Arbalist's topic in Blacksmithing, General Discussion

If your only doing 1, punch , or drill round hole,file star points with triangle or small knife edge file, file, band saw, belt sand ,whatever outside to match inside shape. -

Built a Ray Clontz style hammer in a Clay Spencer workshop in Oct, 2007. It is used 2-4 hrs a day, 5-6 days a week, every week. Has paid for itself many times over. Any parts that have to be purchased are available, mostly the next day.

- 19 replies

-

- appalachian hammer

- tire hammer

-

(and 1 more)

Tagged with:

-

I was informed 3 weeks ago that my currant insurer, Penn National, was dropping me after 8 years. There was never any claims on policy, premiums were alway paid on time. Not sure if the problem was with local agent or company, but communications have been very difficult. After filling out forms for ABANA referral, never had any response. Did get a proposal from a Nationwide company, Scottsdale Insurance Company. Got and accepted proposal from independent agent written with The Travelers company. Thought this info might be helpful to someone.

-

Thomas mentioned octagonal hammers, here's my new favorite hammer. Hand forged by some talented smiths in north Alabama! Little over 2 lbs. Flat on one end, rounded on other. Perfect for a lot of work I do.

-

Just sharing a couple pictures

Al Stephens replied to BuchananFire&Iron's topic in Introduce Yourself

Hi Donnie, Where are you in Alabama? -

VaughnT, very nice fobs. This is the kind of thing we need to hand out at local forge meeting, and see what comes back to the next meeting. Simple, everyone of every skill level can work on, and expand the idea. Thanks for the pics.