mcb

Members-

Posts

48 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Alabama

-

Interests

hunting, shooting, wildlife land management, knife making, timber rigging.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I would assume you would weld proud of the existing surfaces and would only machine this new weld material and as little of the original face as possible while creating a smooth complete face. ETA: I am not going to make a special trip down there but the next time I am in there I will offer them $200 for it. Something tells me they won't bite but it might be worth it for a new project.

-

System for a quick turn down for propane forge to save fuel?

mcb replied to mcb's topic in Gas Forges

That's what I am looking for. Thank You! -

So I have my forge running pretty good and hot. It's a home built twin venturi burner forge made from and old propane bottle and insulated with refractory cement. What I need now is a quick way to turn it down when I take the work out. I know I have seen systems that have a main value with a small adjustable bypass so that you can throw that value and the forge cuts back to a set minimal burn and then when the main valve is opened again the forge jumps back to full go. I am sure I could work it out but I thought I would ask if there are plans for such a system already laid out and debugged. If it was foot actuated that would be even better.

-

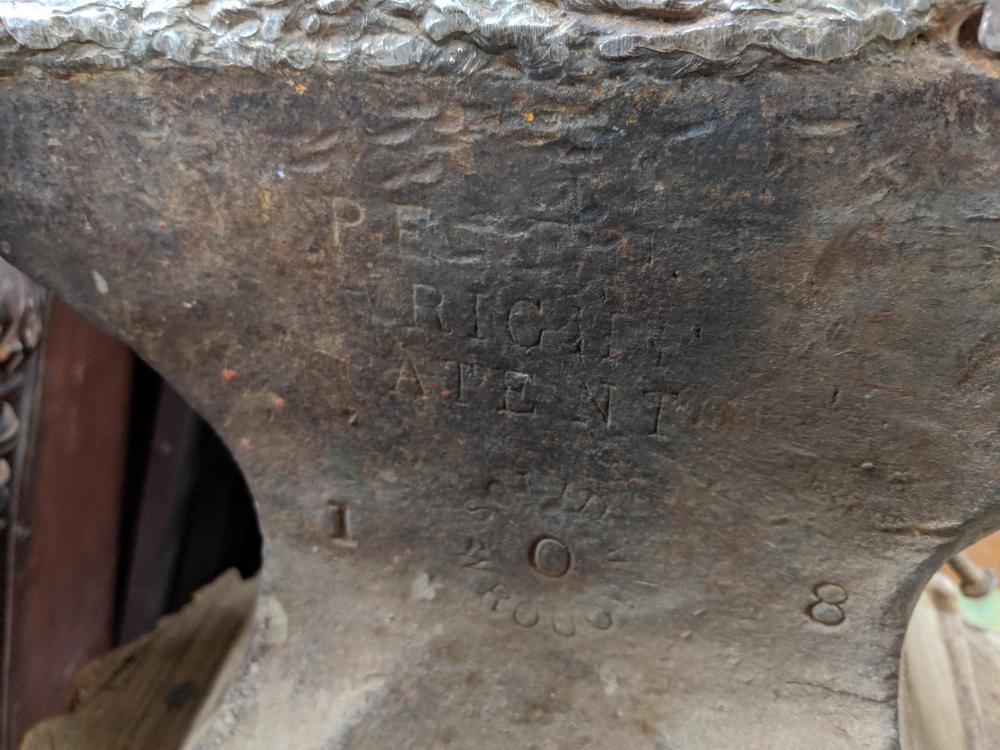

A local antique and collectibles shop has this Peter Wright anvil in the shop. It has been there for at least a year because it was there last November when I saw it the first time and it's still there today and I snapped a few quick photo's. Assuming I am reading the side correctly this is a 120 lb Peter Wright. Unfortunately is had some damage and even more unfortunately the damage seems to have been repaired very poorly. Other than the damage to the one edge the rest is not in terrible shape. First question is can it be repaired into a usable shape? Second what would you pay for such a specimen assuming it could be made usable. $850 seems rather high for it given its condition but since it has been there for at least a year I think I might be able to talk them down. What's it worth? What do you guys think? I am not without an anvil I have a ~80 lb anvil that was likely made in Pittsburgh PA in the mid 1800's. My current anvil for its age it in good usable shape. But having a second bigger anvil is always appealing.

-

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

Thanks jlpservicesinc, that makes total sense and with that knowledge I can see where the lack of a scarf in my weld has cause problems. I will be sure to scarf my next weld. -

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

Thanks BartW,. I have been playing with the blacksmith hobby off and on for the past 4+ years and this is the first time I feel more like a hobby blacksmith and less like a goof pounding on hot scrap metal. I still have lots to learn but it felt really good to succeed at this one skill. It expands the realistic projects I can attempt by a nice notch and that feels good too. -

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

Made another attempt this morning. First thing I did was switch out my burner nozzles. At first I tried .055 and that just turned my forger into a orange ball of fire burping monster. Shut it down and put in .047 diameter nozzle and that seems to be pretty close to a sweet spot for my forge. Using the same IR thermometer I was able to hold 2200F with a peak of 2265F. This time I folded a piece of mild steel over and in the fold put a piece of high carbon steel from a file. I had ground off the teeth and cut off about 1.5 inches of the the file and ground the mild steel clean too. The piece of file got tucked into the folded over end of mild steel. No pictures of it but the folded mild steel covered only about half of the top of the piece of file. Heated it until just starting to turn red and then applied a nice coating of Borax flux. Back into the fire and watched for the Borax to bubble. It did not bubble as vigorously as I though it would so I almost missed it but it did bubble and out it came for firm controlled blows with the hammer. Before it lost too much color it when back in for a second heat and then slightly firmer blows. A final third head and heavy blows and I had a pretty good weld it seemed. I cut the side off the weld with my grinder to expose the weld seams and it seemed to take pretty good. I decided I would attempt to make a small wood chisel from it so I ground the mild steel off of the top side leaving the high carbon steel exposed on one side. I then drew out the weld layer to nearly twice is original length. Figure if it didn't come apart doing that it was a decent weld. I ground off the scale on the edge of the weld and used a sharp file to clean it up and you can see the weld interface and the small separation at both ends of the weld. I will grind those out when I finish rouging in the file. I ran out of propane. Thanks for the all advise and suggesting guys. That weld might not be pretty but it would not have been possible at all without your feedback. Thanks for all the help! -

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

The IR thermometer seems pretty close at lower temperatures. Ice water. boiling water, some eutectic alloys I have and a 750 deg temperature stick I have all come out at the right temperature on the IR thermometer more or less. When I first got it I heated some metal with a propane torch and inside my shop the color and temperature seem pretty close to what is expected up to what a cheap propane torque could do. I would not be surprised if it was off by 25-50 degree at 2000 deg but from my experience its relatively close. That said even if we assume the IR thermometer is right on the hottest temp I got was just over 2100 deg and from the feed back here and other reading I think I am going to need to see temps closer to 2300 deg inside the forge to have a chance of welding at the anvil. I have a couple old files in the scrap bucket I was saving for various projects. I will cut a chunk off one of those and try to weld it to some better quality mild steel on my next attempt. Assuming I can get the forge a bit hotter with a nozzle change or some other improvement. Thanks guys! keep the suggestions and feed back coming its is greatly appreciated. -

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

Thanks, the mud is getting at little more watery at least. I did not flux inside the joint I was trying to make only fluxed after I had put the two surfaces together, so that no doubt did not help my attempts. -

First serious attempt at forge welding, failure...

mcb replied to mcb's topic in Blacksmithing, General Discussion

Thanks guys that was very helpful. I will see what I can do to get some known good tool steel or high carbon steel without nickle or chrome. I will also see if I can get my forge a touch hotter too. The hard to read colors working outside and my eyes is why I bough that IR temperature sensor. I am guessing I need to be seeing 2200-2300 degrees in the forge to have the steel hot enough to weld by the time it gets to my anvil. I think I might need slightly larger diameter fuel nozzles as I still think I am injecting the fuel too high of a velocity drawing in too much air in with it in my burners. It's hard to get a reducing flame even with the airflow choked way down. It goes from neutral to extinguished with very little reducing flame in between. Fatter nozzles might let me get more fuel into the forge without overdoing the air too much. When I first built the forge I was using .025 MIG tips as nozzles going to .035 made a noticeable improvement to the temperature. I have a bunch of extra tips so I might drill some out to .047 and see if that helps get my temperature up a bit more. I also need to get my propane tank into a large bucket of water, about half way through the session I froze it pretty hard and that was hurting my fuel output too. -

So I have a new gas forge and after a few session to work out the kinks I made my first serious attempt to forge weld some steel. I was not trying to make anything specific, just trying to learn the welding process. My process was to clean a piece of steel especially the surface I was folding to attempt to weld. Heat it and notch the underside with my hot-cut. I then folded the steel onto itself at the notch making sure the two half were tight to each other. Another moderate heat and fluxed the edges to seal the welding surfaces with Borax. I then put it in and got it as hot as my forge would go. I took it out and with moderate blows drove the pieces together before it had lost much color a reheated and repeated a second heat with moderate blows. After a third heat I switched to pretty heavy blows and then tested the weld. In all three attempts I got no weld at all. My first two attempt were with some low carbon steel probably 1018 or 1020 (Home Depot stock). I had heard/read higher carbon steel welds at lower temperatures and so my third attempt was with a scrape of car spring. I am fairly color blind and working outside in the hot Alabama sun and those two challenges makes it hard for me to read the color/temperature so I bought myself an infrared thermometer rated to 2700F. The highest temperature I had on my parts was just over 2100 F. I suspect this is why I was not getting a weld but wanted to see what you guys thought. Am I hot enough? Am I missing something else? Thanks in advance.

-

Nice find. The spring and mounting hardware at there too! I would paint it but down here in Alabama the humidity is so high in the summer mine was rusting just laying on the bench in my shop after I took a wire wheel to it to get the surface rust off. Not sure if it's "correct" to paint them but I did to keep mine from rusting.

-

Started out with about 4-inches of 1-1/4-inch diameter 4137. Tapered one end and then upset it directly into the hardy hole on my anvil. That got the anvil pretty hot after doing that several times to get an upset collar. I was hoping for a more pronounced collar but I think this will work pretty good for my projects. I forged the cutting edge down to about 1/8 thick and then did the rest with grinder. I quench it and then tempered it in a 450 deg oven (two 2-hour soaks). A file bite into it about as well as a cheap big-box store ax head so I think it's tempered down enough to not be too brittle for use. Here is the finish hot-cut next to the stock it was cut from. This is right after quench but before temper and final sharpening. Finish hot-cut in the Hardy of my little anvil. It's probably a bit bigger than it should be for my little ~90lb anvil but too big is probably better than too small.