Chris Williams

Members-

Posts

273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chris Williams

-

Forget the camp fire removing alloying elements part; it doesn't work like that. As for packing alloying elements around an iron/steel bar, encasing it in clay, and heating it up high enough for long enough, you have two possible mechanisms that could credibly create the "case" that you seek. If you are able to control melting to only include the very outside of the bar (i.e., through careful control of temperature AND time, or some creative measurement or observation scheme), then it could work like I (think) you envision it. How well it works would depend in part on the melting points of your alloying elements and their solubility in the steel. Alternatively, you can perhaps select alloying elements that have lower melting points than the steel, and which would then dissolve the steel into the melt. In either case, heating too high or low for too short or long would yield a disappointing result. The second mechanism is diffusion, and is the same mechanism that causes carbon diffusion into steel during case hardening. Time and temperature will determine the result here, along with selection of both a starting steel composition and alloying elements that will readily promote diffusion. You would likely have some degree of both mechanisms occurring depending on a myriad of factors. The flour or other carbon source would help prevent oxidation and therefore promote diffusion (including of carbon) into the bar, but I don't know how it would behave with molten materials. I suspect that it may prevent your metal powders from consolidating with the bar or each other. This is far too open ended and vague of a question for me to go into much depth, but the bottom line is that your idea can be made to work with at least some materials, and likely quite a bit of experimentation. I have a number of ideas, but would likely just weld a cladding material onto a piece that I wanted some different property in rather than trying do it through diffusion or carefully controlled (non-welding) melting. Frazer also brings up a good point about canister Damascus, in that you may be able to make much more controlled materials that way. Now doing it just to do it... I could get behind that!

-

Possible Iron Source?

Chris Williams replied to Gilvar's topic in Smelting, Melting, Foundry, and Casting

It might make sense to evaluate my cemented layer that is around 4-5 feet deep. It is a little yellowish. I had never given any consideration to it perhaps being iron containing. I'm certain that it has too much silicon in all of the sand that would accompany it though. I would have to add crushed shells to keep from losing too much iron to iron silicates. I would have to relearn my mass and energy transport material so that I can just calculate the right quantities if it turns out to be useful ore. As for the old sites - I am sure that records detailing the 1860s production can be had. That area is not too far north of me. -

Possible Iron Source?

Chris Williams replied to Gilvar's topic in Smelting, Melting, Foundry, and Casting

https://ufdc.ufl.edu/UF00099286/00001/42j OCCURRENCE: Bishop and Dee (1961) reported that a deposit of limonite exists near Chiefland, Levy County. They also reported a deposit of yellow ochre in Flagler County. Limonite gives rust-colored stains to soils, limestones, and clays; in larger amounts it acts to cement sand grains and clay particles into hardpans or concretionary forms. -

Possible Iron Source?

Chris Williams replied to Gilvar's topic in Smelting, Melting, Foundry, and Casting

Some elaboration on Thomas's comment on the richness of your ore can be found here: https://www.tf.uni-kiel.de/matwis/amat/iss/kap_a/backbone/ra_2_4.html -

Yes. If you ever find yourself wanting to use it, clean it up almost like you would a hammer face. Make sure there are no sharp edges, and you want a very slight dome to it.

-

There are portions of the summer here where you could lose a child or pet in two week old grass. I've occasionally mowed twice in a week. It depends on how much rain we get. I make a point to avoid any place where there is an HOA or covenant. I don't need to be any place where someone with nothing better to do than measure my grass or compare the color of my mailbox to a paint swatch with the official color to marginally improve their home value can cause me work or hassle.

-

I could see the rotation being somewhat unpleasant with a bone spur. I'm only semi-country, as I have a lot next to a subdivision. I'm sure the 10 neighbors on that side wonder what went wrong for someone to buy the commercial ag zoned lot behind them to actually use it that way. The previous owner kept it as a huge lawn.

-

There are at least two US distributors for Schröckenfux scythes that are made in Austria, and there are other valid options available as well (typically from Central or Eastern Europe). "European" style here does not include Britain, as their scythe style is basically the "American" scythe, which may or may not more accurately be called the "English" scythe. I admit to not having researched that enough to know where it actually originated. Sharpening sticks with sand/oil or (now much more commonly) whetstones in water are used as needed while mowing, and peening is required less frequently to reestablish a thinner edge that is then sharpened with the sharpening stick or whetstone. I am not willing to give up modern mowers for cutting large lots, but I'm quite fond of my European type scythe for trimming of weeds in the pasture before they go to seed or most anywhere I would otherwise use a string trimmer. It also serves admirably for mowing small areas. I prefer it to my American style scythe and string trimmer for wherever I want to use one.

-

Blowtorch capable of heating rivets?

Chris Williams replied to B3NDY's topic in Welding/Fab General Discussion

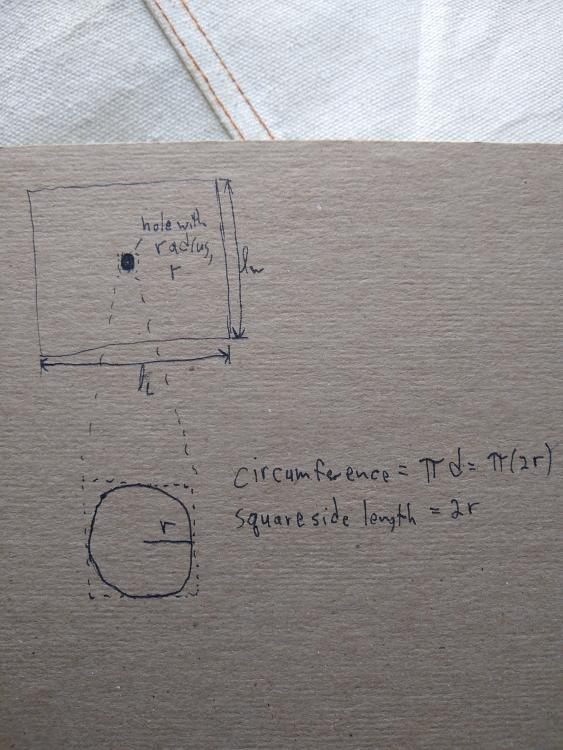

The astute reader may now be wondering, "What about a hole in the center of a large plate?" If you heat the plate evenly, then the hole expands in proportion to the plate. Circumference = pi * diameter = pi * radius * 2. The length of the side of a square around said circle = radius * 2. They expand and contract in proportion, provided there is no external constraint such as uneven heating. I leave any attempt at determining specific conditions suitable for shrinking a hole with the addition of localized heat as an exercise for the motivated reader. -

Blowtorch capable of heating rivets?

Chris Williams replied to B3NDY's topic in Welding/Fab General Discussion

You're welcome. For the wagon tire, the hole gets bigger because the whole gets bigger. If you were to measure the full part at room temperature and at fitting temperature, then the wheel (and all features!) would be scaled up proportionately according to the CTE. The length (i.e., the circumference) would increase on I.D. and O.D. by the same proportion. If you make two wheels from two bars, and one bar is longer, then the wheel made (with no other differences) from the longer bar has the larger radius. There is one other slight difference that I need to point out for clarity. I previously said that the metal expands uniformly, but disregarded the increase in thickness and width in my example just now. Why? Simply put, there is far more length dimension than width or thickness dimension for the wagon tire. The thickness and width also expand, but nowhere close to as much as the length. -

Blowtorch capable of heating rivets?

Chris Williams replied to B3NDY's topic in Welding/Fab General Discussion

You've basically got it right, with a slight clarification being that the metal expands uniformly in all directions with increase in temperature, and shrinks uniformly in all directions with decrease in temperature. A coefficient of thermal expansion (CTE) is basically a length change per unit length per degree [length change/(unit length * degree)]. If you increase the temperature by one degree, then the metal expands by the length change for every unit length. For numbers, "mild steel" is listed by one reference as having a CTE of 5.9*10^-6in/(1in*1 degree F), or 0.0000059in/(1in*1F). If you heat up an entire part uniformly, then that part will expand uniformly by 0.00059% per degree F. If you heat one side but not the other, then the heated side expands but the side that was not heated does not. The heated material wants to expand uniformly, but is constrained by the side that was not heated. Whether a particular feature expands or contracts locally depends on the balance of forces in the local region of the part. The variables include part geometry, the material(s), what the temperature(s) are, what the temperature gradients are, and whether there are other forces acting on the part. To your observations, there can be conditions where you can make a hole shrink by precise application of heat while the remainder of the part remains relatively cooler. This occurs when the balance of forces local to the hole prevent uniform expansion outward from the hole centerline but not inwards; the hotter material will expand somewhere, even if it has to crack itself to do so. -

Quite nice! Any glow-eye pictures?

-

You've got it right. You can use bricks as a wall to reduce the quantity of coke that you need to pile up to reach the same height, if that is convenient or useful for the task at hand. [Note for charcoal burners: charcoal will all combust and burn away just from the oxygen in the air, so you cannot just pile up fuel higher and higher. In this case, the bricks are more necessary to avoid burning excess fuel.]

-

Christmas 2020 is headed this way

Chris Williams replied to Glenn's topic in Blacksmithing, General Discussion

I agree about the quality of modern kids tools. I remember having a wooden toolbox with a good variety of reasonable (although not great) quality kid-size tools that I got one Christmas; this is the kit that I want to reproduce. I found a more modern but lower quality version at a thrift store that I bought to remind me of what all was in the kit and how to build the wooden toolbox. I just checked to take a picture, but I've apparently reorganized it into a hiding spot. Thanks for the idea of resizing tools. I wasn't looking forward to filing that many saw teeth, and cutting old ones down is a great idea. Several other tools are good candidates too. -

Christmas 2020 is headed this way

Chris Williams replied to Glenn's topic in Blacksmithing, General Discussion

Haha! COVID-19 gave my wife and I additional kindergarten/1st grade teacher and daycare provider responsibilities in addition to full time jobs that have not slowed down any (my wife gained several new responsibilities due to COVID). I hope to catch up on the Christmas presents that I meant to make last year! We're blessed to have our jobs, so no complaints! My plans are to make two types of ornaments: -Icicles with a modest amount of brass brushing while hot for accent color, and -Trees chiseled out from lawnmower blades with chisel/fuller/punch indents for tinsel, streamers, ornaments, and stars. Deburring would be accomplished by chisel/stone of sharp features followed by tumbling to smooth everything. Longer term (next year and the year after), I want to make tool sets for all of my kids, nieces, and nephews. One set would be the standard hammer, saw, chisel, etc. tool kit, and the other would be a set of garden tools. -

What did you do in the shop today?

Chris Williams replied to Mark Ling's topic in Blacksmithing, General Discussion

I really like the bookends! -

Making my own flux

Chris Williams replied to Benona blacksmith's topic in Fluxes used in blacksmithing

Specs tend to control bulk properties and define allowable types, sizes, and spacing for defects. The drilling issue in A36 could easily be due to hitting an inclusion. This does not apply to all anecdotes presented, but several are within the allowable variation in the material. Plus, for those that only control a limited number of properties (typically tensile strength) to a minimum and with no control over heat treat response (because the product is intended to be used as delivered or isn't meant to be hardened), it should not be surprising that the material is inconsistent in other ways that are not controlled by the spec. The behavior of the material once it has been further thermally processed (by us) is out of scope of the spec entirely. -

I didn't say that I don't buy from antique stores; I just don't pay antique store prices! The auction search could take a couple of months. I just kept my eyes open while I still needed a vice. Now I have 4, and I only overpaid on the first one (locally in person) due to impatience. I've got to make a couple of springs and a mounting bracket, but that is easy.

-

For vises, I actually bought a couple (4.5 and 5 inch) on ebay shipped to my door for $80 and less. Just need to watch auctions for a while. One eventually gets missed by the crowd. I don't know why this happens, but I did it with a blower too. TPAAAT (check out the sticky) is the preferred cheap way to accumulate equipment. I'm not quite as cheap as Thomas, but am also not prone to paying typical antique store prices for usable tools. The trick is to find the person that has it and either doesn't know what it is, or does know and just wants it out of the way or in the hands of someone that will use it.

-

He was at the FABA conference in Ocala two years ago. I wish that I had known to ask him to bring some!

-

I'm quite a fan of wood fired pizza as well. I have pizza stones for my kamado Joe, but I may prefer the crust directly on the grate. It cooks incredibly fast, though, so you have to cook one side ~30 seconds, flip, add cheese, thin (precooked if cooking is required) toppings, and already-hot pizza sauce, in that order. Temp for cooking is >1000F. Each pizza takes between 1-1.5 minutes. I think it is obvious, but use very thin dough.