Chris Williams

Members-

Posts

273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chris Williams

-

What did you do in the shop today?

Chris Williams replied to Mark Ling's topic in Blacksmithing, General Discussion

I like my cordless Dewalt angle grinder. It is super convenient when there is not an outlet nearby. I don't know for sure that the 18/20V converter (really just a pass-through) was the cause, but I had a battery with power still in it that wouldn't charge again after I left it installed in the converter overnight. The battery had discharged too much and the charger wouldn't charge the battery. I suspect that the converter either has a small internal resistor somewhere or else it somehow got shorted (i.e.,if the converter was the cause). I used another means to get the voltage higher in the battery, and it charged fine again. I just make sure to keep the batteries out of the converter when I am finished using it. -

Large Struck Tool ID Request

Chris Williams replied to Chris Williams's topic in Tools, ID, and pictorial reference

Thanks for the additional replies everyone. I've looked at caulking tools extensively in the past, and agree that it is unlikely to be a caulking tool specifically. I performed the center punch drop test, with the following results: drop 1-hit more rusty place and discarded "dent" result (not clear that dent was into tool material rather than into rust and stopping at iron/steel); drop 2-no dent, but also could be influenced by surface rust; drop 3-let go of the punch unevenly and it tilted before impact, and the punch left a tiny raised bur in the face where it impacted/tilted at the same time. Conclusion -- face is not hardened. The chisel marks in the side should have already told me that, really. I'll have to spark test the face and body to determine if it is WI/mild steel/higher carbon steel. I could see it as a planishing tool. The person holding it could walk the curved face incrementally across the surface to be planished, but they would have to be careful not to tilt it side-to-side and create marks at the edge. I could also see it being a fuller, but the general lack of wear on the face edges compared to the mushrooming suggests to me that the face was used on something much more soft than itself, or else those edges themselves did not often serve as a working surface. -

Large Struck Tool ID Request

Chris Williams replied to Chris Williams's topic in Tools, ID, and pictorial reference

Thanks for your thoughts Frosty. With the mushrooming present on the struck end, the tool was clearly used hard, but the working end doesn't have appreciable deformation from its primary function. I think it is certainly reasonable that the tool was compacting or forcing something that had more give than steel or stone. There are many chisel marks from a secondary use as a backup tool for cutting. I had considered it not of "archival quality" due to the mushrooming, chisel marks, and one small saw cut that I found. However, I am not in any hurry to do anything with it, but rather intend to understand what I have found first. If it is a truly unusual item, then I will keep it intact. -

I picked this up today at an antique store. The label said "railroad hammer," which is obviously not correct, as it is some type of struck tool rather than a hammer. Does anyone recognize its intended purpose? I'm guessing top swage, but realize that there are many industries which may have used such a tool for purposes that I am not familiar with. It is a little longer than 9" long, with a slightly curved 4"x2" face. It was forge welded together out of at least two pieces, with a clear weld joining the curved 2"x2"x4" stock which formed the working end to the body. There are some "cracks" in the eye which look like "birth defects" rather than damage from work or abuse, and no evidence that the "cracks" got bigger over time. I think they formed during the hole punching or drifting (tapered one way only). The struck end is in dreadful shape, and would certainly require dressing prior to further use as a struck tool. I don't have any plans for such work, and will likely leave the mushrooming alone or grind it minimally to better fit into a hole in a log as another stump anvil option next to some other assorted make-do small anvils with other shapes.

-

The aspect that most appeals to me about metallic glasses is how they seems to be the result of the atoms trying to arrange in five fold symmetry. Many of you will recognize that there are no natural crystals with five fold symmetry. I don't know if any crystals have been created in labs with other than local five fold symmetry. I won't pretend to have researched it well enough to explain myself, but I will seed the conversation with a link. https://www.nature.com/articles/ncomms9310

-

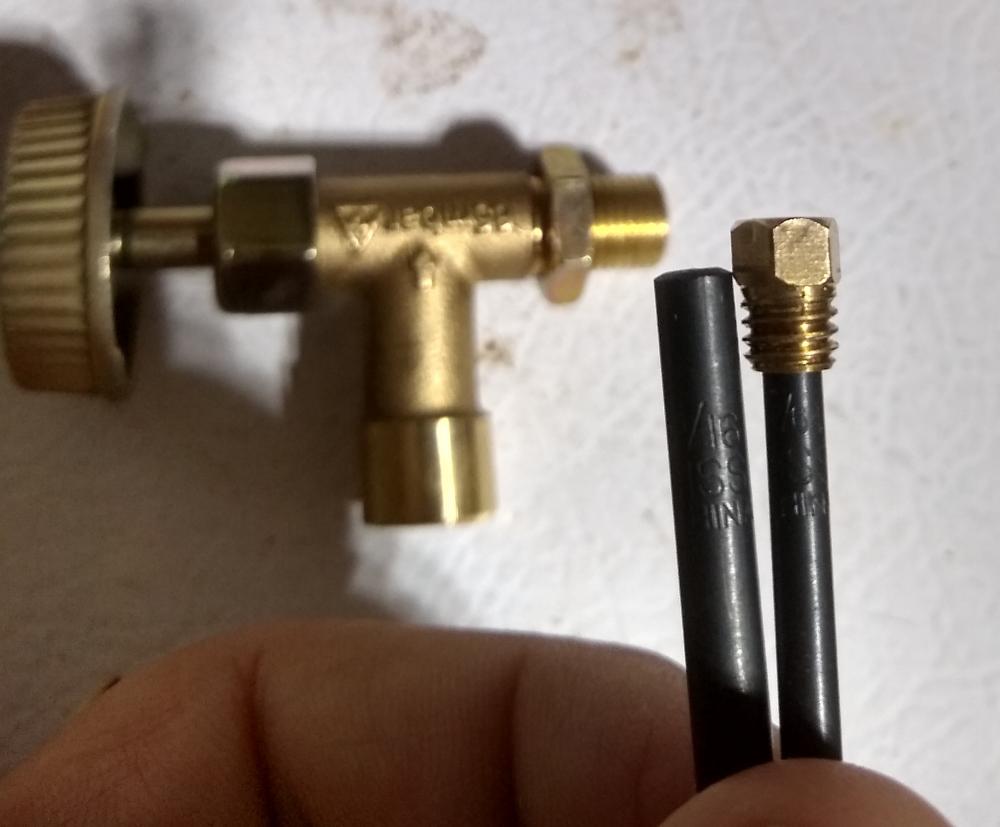

Thanks Mike. I know that the measurements are available, but I still need to get parts in hand to turn them over and measure them myself and poke them to actually get it. I also bought some lengths of tube that I can tap one end and thread the other (post-solder) to extend the Hoke tips where needed. I got two of the two-pack Mensi valves to experiment with. I was going to try to make one each 1/8", 1/4", and 3/8", with the extra being a backup.

-

Thank you for clearing that up for me, Mike. Jewelers Toy Store, Contenti, and Otto Frie Jewlers each had acetylene tips and torches. Without knowing any better, I did not think it the slightest bit unusual. I was also considering soldering the valve threads as you suggest (but hadn't thought of aluminum, which I do prefer now that you mention it), but that is plan B. I first want to try to make a reducing bushing out of the original Mensi orifice. I am including two pictures below. Both show a 9/64" drill bit which is only slightly loose in the bore of the orifice piece (the orifice itself being smaller, approximately 1/16" at the end). The more close up photo also shows a 3/16" drill bit lined up behind the orifice piece (the tap drill is probably a #20 or a #23 - still trying to verify). There is very little clearance, but the drill bit is also angled slightly. I don't know know if I have the skill set to open up that hole correctly or not, but I can go straight to working on the valve side if it doesn't work out.

-

Do these orifice sizes apply for each of the tip types -- acetylene, propane, and natural gas? I haven't found the orifice dimensions listed at several different vendors. I cannot think what else would be different about them if not for the orifice size. I would like to know if you know what type of thread the 3/16-40 Hoke tips are also. I have found options including UNS, ME, and UST (Universal Straight and Taper). Since the Hoke tips are gas fittings, the UST seems to make sense, but it is specific to model builders and may be too obscure to be in the Hoke Product. Is it perhaps something more common like NPT? I would like to try drilling and tapping the orifice of the Mensi valve to take Hoke tips. I suspect that there may not be enough wall left, but if I can find the 3/16-40 tap and drill measurements, then I can measure closely and do the math. I did find some 1/4-40 to 3/16-40 reducer bushings for sale, which gave me hope that I may be able to.

-

Hardening Mild Steel

Chris Williams replied to Blacksmith Jim's topic in Heat Treating, general discussion

I don't have the patience to type out a full summary of the paper on my phone, but it is only 5 pages and well within the understanding of anyone that wants to read it (perhaps with limited searching for jargon definitions). The paper does not say that the material with higher volume % Martensite is softer than the material with lower volume % Martensite, but rather that the material with lower volume % Martensite has higher wear resistance. More on that in a moment, as the conclusion should be qualified. On what may be causing the confusion on Martensite and material hardness -- The authors used microhardness testing to determine the hardness of individual phases (Martensite and ferrite) for each processing condition, and the Martensite in the material with lower volume % Martensite was harder than the Martensite in the material with higher volume % Martensite. No bulk material hardness measurements were presented. Each of the specimens were tested in a device which caused a cylinder of steel with HRC 50 to rotate against the specimen with a constant force and speed for a specific distance (i.e., length of surface contact). At 5% distance intervals, specimen weight loss was measured, and these measurements were plotted for all specimens. The specimens were replaced into the test equipment with a new surface touching the cylinder each interval to reduce the potential impact of changing surface area. The conclusion that increasing volume % Martensite correlates to lower wear resistance was surprising to the authors as well as it is to us. The authors proposed that some energy was absorbed in deforming the ductile ferrite. The increase in wear resistance correlated both to the ductility of the ferrite as well as the hardness of the Martensite. I have quoted the "take home" paragraph below. "The difference between input and output energies of a tribological system during friction is predominantly frictional energy. Some energy is consumed by deformation and fracture. The consumption of some deformation energy in ductile phase decreases the energy for pure deformation. The consumption proportion of the deformation energy input to the system in the ductile phase depends on the proportion and ductility of the ductile phase. When this proportion and ductility increase, the consumed energy also increases. It can be stated that the proportion of the consumed deformation energy is increased by increasing the ductile ferrite phase proportion in the structure consisting of Martensite and ferrite phases. But the structure should be supported by hard Martensite phase to increase the wear resistance. For this purpose, it is understood that dual phases obtained with lower Austenitizing temperatures provide higher wear resistance." So about the qualification that I mentioned earlier... The specimens used were of one composition and five processing conditions. The highest wear resistance was also the specimen with the least volume % Martensite. It is unlikely that the trend continues unchanged down to 0% Martensite, but the breakpoint was not determined by further experiments. Furthermore, changes in the cylinder hardness, rotation speed, or force would also likely change the optimal distribution of ductile ferrite and hard Martensite. Also, for those curious -- the hardening media was water, salt, and ice. -

What did you do in the shop today?

Chris Williams replied to Mark Ling's topic in Blacksmithing, General Discussion

...on dry land, let alone swampy land or water, where their advantages are greater! They can also climb chain link and some other fences, as well as some trees (usually when they have low branches or a pronounced lean). It pays to be aware of your surroundings when you are out and about in their territory. I've even seen one alligator crossing the road (from the beach side of the road, and towards a marsh) where the tail and head both extended a few feet beyond the lane it was currently in. This wasn't the biggest that I've come across, but it was leaving the beach (Canaveral National Sea Shore) I was just at! -

Foundry burner trouble

Chris Williams replied to Teddypenta's topic in Smelting, Melting, Foundry, and Casting

What does the seller say about tuning it? I'm not a burner expert in any way, shape or form, but I do notice that your burner does not match the published design (see link). That does not mean that it won't work (great, poorly, or somewhere in the middle), but the published design is a place for you to start diagnosing what the difference(s) is(are) and perhaps what tuning or changes that you need to make. That said, just because it looks like a Frosty T burner, doesn't mean it IS a Frosty T burner. Lots of people have bought look alikes, and some are so far from the design and poorly functioning that they're not worth trying to fix. Hopefully you got one that will work. -

Yes, sometimes the economics of a product requires specific scrap feedstock. That is just a risk inherent in the product type. I'm still on the lookout for a searchable scrap yard near me. There is a promising-looking complex nearby that I've never seen anyone at. It looks almost like a family house and light industry with adjacent large resource pile.

-

Sell all of the LHDDs for 4Qls from the start. Always consider replacement costs when selling a product. Of course, for a product, you need to be sure of the material quality and presence/lack of defects before you use scrap or other alternatively-sourced material.

-

Floor options for shed wooden floor

Chris Williams replied to MarriedWithAnvils's topic in Building, Designing a Shop

I'm glad you pointed out the "tested and current" part. I had a Kiddie brand CO and propane alarm that wouldn't detect propane brand new and with a new battery. Never trust your life or health to something that you haven't verified. -

Looks nice. What do you use under the leg when you move it? I know that the RTV-adhered plate won't be moving along with the vise. I thought it may be convenient to use more of the 1/8” steel plate with something on the floor side as an anti-skid.

-

The straps will work great to hold down your anvil, so long as you keep them near room temperature. I wouldn't be able to manage that long enough to make it worth using straps to me. Don't breath the fumes when they burn. I recommend putting bolts through the foot holes, or screwing metal strapping down over the feet, or bolting bars over the feet, or bolting eyes down to the spool and using chain and turnbuckles to hold it to the eyes, or... anything else that is non-flammable.

-

See my response to your IM for more details, but yes, I was happy with their service. Shipping was basically 3/4 of the way across the US, and was typical for freight shipping of that distance to a residence (i.e., add one day for them to transfer to a local company with a lift gate truck if you need one). This was all 7-8 years ago, so it may or may not still be the same.

-

Show me your anvil stands

Chris Williams replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I see that the nuts aren't tightened down on the lower ends yet. Save yourself the effort now and put some thick washers between the nut and the wood. If it were mine, I would use a forstner or spade bit to make a flat spot for the washer to sit in. It's hard to keep the spade bit centered when there is a hole already, though--you could tap a wooden plug into the hole to give the center point something to bite into, if needed. The nut by itself will dig into the stump when you tighten it down. It may work great and seat into the wood, or it may eventually be the cause of a split as you tighten it up over time as the nut keeps digging more into the stump during use. If you use a washer, the wood will compress some, but it shouldn't continue digging deeper over time. -

Sandbox stand for anvil

Chris Williams replied to Iron Kitten Forge's topic in Stands for Anvils, Swage Blocks, etc

I used to pick up my 275 lb anvil. It hasn't been that many years, but I now I have more sense and fewer muscles. I use cribbing to lift it now. I use a 1" square bar in the hardy hole to tilt it and add the next piece. See the description in the linked thread. -

It's good to hear that they fixed the issue. I saw several design features that had been incrementally worked on (with improvements and otherwise) for years or even decades without adequate resolution. I was typically working with stuff that was one or more generation old, and the rotating compressor parts were typically titanium alloys. I don't know what is in the current generation engines. I haven't worked with aircraft in years now. I guess that keeping expensive parts might make sense if you have a cost+ contract or you make a percentage on the parts. I was always on the using end and didn't appreciate the expensive parts made from Unobtanium.

-

Most engine bearings that I encountered were 52100. There were some other alloys used, but nothing particularly exotic. It doesn't have to be a big piece of shrapnel to ruin your day, either. I've seen crashes from smaller shrapnel (such as a single thrown turbine blade) cutting fuel lines as well as from shrapnel hitting a remaining good engine. Bigger chunks from a fragmenting disk have tremendous energy, and are even more destructive. Even though I know the odds of an event are miniscule, I don't like sitting in the plane of rotation of the turbines or compressors.

-

Sloss furnace is in Birmingham, and Tannehill Ironworks is nearby.

-

Ask versus Guess culture

Chris Williams replied to rockstar.esq's topic in The Business Side of Blacksmithing

That makes more sense. I was thinking that one would have to know the guessing "rules" of the others to guess correctly, but I hadn't considered guessing into the aether "fishing" for one random person accepting of the "guess" out of many hearers. -

Ask versus Guess culture

Chris Williams replied to rockstar.esq's topic in The Business Side of Blacksmithing

I saw a bald eagle steal a fish from an osprey this afternoon. It seems that I see this behavior occur at least every couple of months or so. In fact, I don't know that I have personally witnessed a bald eagle obtain food in any other way. If I didn't have other sources, I would say that our national bird is exclusively a fish thief! How much of this type of comparison is based on the biases of the observer? I was unfamiliar with this sort of framing, but I suppose that I could talk myself into seeing "guess culture" in some people I know. It seems to me that anyone working purely in that paradigm could only have effective relationships with a very small and unchanging circle. How does the type persist in a world that is becoming much more interconnected? -

Some of them were repairs of broken ships. On the ship my step-granddad crossed the Atlantic in, one of the other soldiers on the ship started looking closely at the hull. The guy went to examine a few places, and then realized that HE had welded it back together after it broke in half in the Great Lakes (I don't remember which one). The welder spent the rest of the trip telling others, or just saying to himself, "my welds will hold... my welds will hold!"