Chris Williams

Members-

Posts

273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chris Williams

-

"You load sixteen tons, what do you get? Another day older and deeper in debt Saint Peter don't you call me 'cause I can't go I owe my soul to the company store" In the US, it is the employer's responsibility to provide PPE when it is required for the job. Any business that handles it differently is treating YOU as the consumable, and likely breaking the law! OSHA FACTSHEET PPE https://www.osha.gov/OshDoc/data_General_Facts/ppe-factsheet.pdf

-

Stainless question, electropolishing, etc

Chris Williams replied to somber crow's topic in Finishes for Metal

You'll want to remove any forging scale and then passivate. -

A sheet or two of hardiboard or equivalent cement board wouldn't cost that much (~$35 for a 4'x8' sheet). You can replace just where you want the chimney to be, or a full wall. Make sure to use a wet process to cut it, as the dust is a real hazard. I haven't bought them before, but I just priced steel studs, and they aren't much more than wood. Check out the hardiboard installation guides before committing to this combo though.

-

https://www.sciencedirect.com/science/article/abs/pii/S2352409X20303692 Found it. "Firing up the furnace: New insights on metallurgical practices in the Chalcolithic Southern Levant from a recently discovered copper-smelting workshop at Horvat Beter (Israel)." Unfortunately, this article is not open access.

-

Thomas, I am not. How would I go about having placement on the list?

-

Thomas, The only copper oxide reduction I've performed personally was with hydrogen gas in a TGA. I didn't smell a thing, honest! (Even had there not been an exhaust connected to the fume hood exhaust, I would not have noticed a few grams of H2O vapor in the lab.) SLAG, I am glad that you find the information to be of value. I must admit that "open access" was not particularly common during my academic years, and I hadn't thought to look for such a resource before. Stash and Frosty, You're welcome for the links. I remember while growing up that although I could find a few books on ancient technology in the library, many details were shrugged off as lost to the sands of time. It fascinates me to see what we have learned since.

-

"Play sand" is crushed, at least whenever I buy it. In fact, I don't know of any local place where I could get bagged riverine sand readily. Your sources may vary. Find a bag with a tear and inspect a little bit of it. You'll be able to feel if it is sharp or not.

-

The video only showed the nozzle, which looked modern; it wasn't obvious just what they were using. As the article has been edited in place (again!), I don't know the paper name to look up the details. I have found that whatever the name, it is (will be?) published in the Journal of Archaeological Science, which is open access! I haven't found it yet searching their articles for "copper" or "copper smelting." I did serendipitously stumble upon "Towards better reconstruction of smelting temperatures: Methodological review and the case of historical K-rich Cu-slags from the Old Copper Basin, Poland" https://www.journals.elsevier.com/journal-of-archaeological-science https://www.sciencedirect.com/science/article/pii/S0305440320300649

-

What about decomposed granite?

Chris Williams replied to Tokum's topic in Stands for Anvils, Swage Blocks, etc

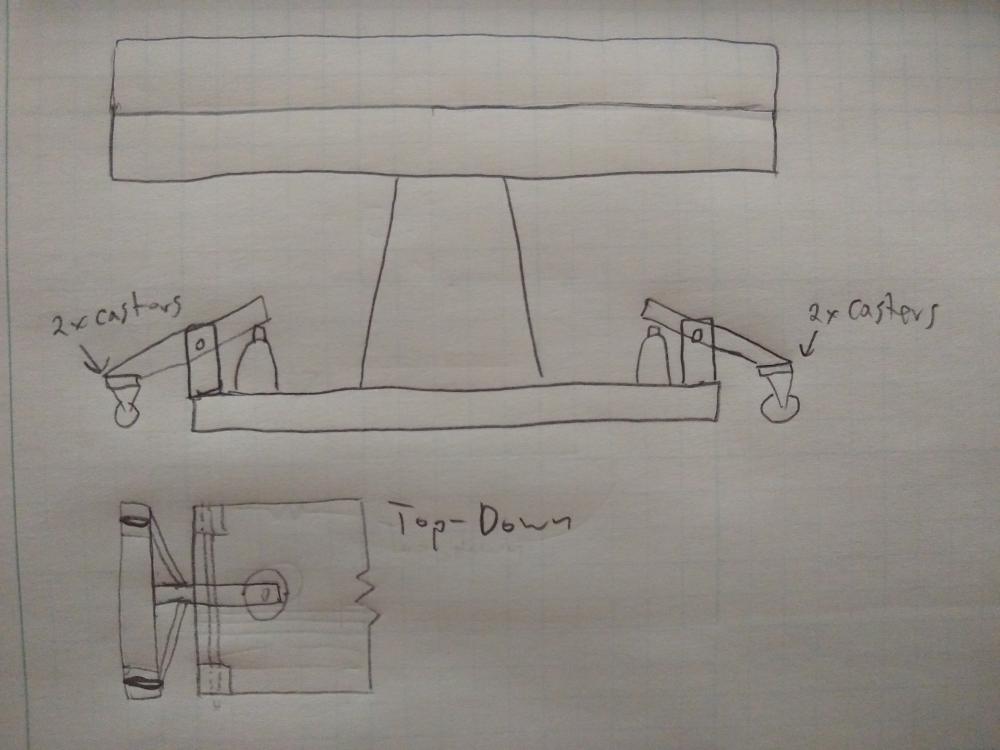

Plus, I'm standing on it going up, and having to use my hands while kneeling or bent down to try to let it down slowly. I like the hydraulic idea. I've got two bottle jacks that I picked up cheap that I can probably rig to push up on a lever that would push two (different style, replacement) casters mounted on the other side of a pivot down. It would be more convenient in a self contained form factor, though. I don't know if this idea helps anyone or not, but the fact that I'm raising / lowering a jointer with it is just details. The corner posts are already in my current platform, but I would add new ones closer to the center to better support the pivot if I get around to building this. For the OP, I think the selected casters will work fine. The anvil doesn't care about an abrupt stop when lowering it. -

What about decomposed granite?

Chris Williams replied to Tokum's topic in Stands for Anvils, Swage Blocks, etc

Yes, but the mechanical advantage belongs to gravity with such a short lever relative to the long wooden platform I built to keep it mobile but steady. My jointer is a large cast iron unit and weighs a lot. -

Well, I don't know what to think about this... Now the article doesn't mention the research paper name. The video (short ~1 minute as you noticed) isn't embedded anymore, but there is a link to a Facebook page. I don't use Facebook, so I searched out the project name and found this: https://www.tau.ac.il/~ebenyose/CTV/index.html I think I may have found a university page for the individual responsible for researching the site, but that is speculative. http://journals.ed.ac.uk/lithicstudies/article/view/1678/2303 This is the same general location but different period.

-

What about decomposed granite?

Chris Williams replied to Tokum's topic in Stands for Anvils, Swage Blocks, etc

I've got some casters that look like those on my jointer. I like them except for how hard they drop the jointer whenever I let them back down. I've been meaning to move them to an anvil stand where that isn't an issue. -

You're welcome. I didn't read any banners or tabs, so I hadn't noticed that they demanded subscription. I was able to read the whole thing and watch the video just by following the Google News link. The news article did provide the name for the academic paper, but I hadn't had time to look for it, and certainly wouldn't have the journal subscription needed if it wasn't public (which is likely).

-

Justin’s Smithing progression. [PIC heavy]

Chris Williams replied to Justin Topp's topic in Member Projects

Awesome! I hope you get lots of good forging time in the dry and the shade now! I hope to have somewhere covered before too long also. Also, I'm no framer, but don't you want that rafter to sit on the post? It looks like all the load is in shear on your screws/nails. -

https://www.timesofisrael.com/evidence-of-first-metallurgy-furnaces-from-6500-years-ago-found-in-beersheba/ Link is to an article that describes a recent find of early furnace designs and a short video of an experimental archeology version of the furnace.

-

The part that I thought about is: "While working on the 14th floor, some bricks I had to clear Now, to throw them down from such a height was not a good idea The foreman wasn't very pleased, he being an awkward sod He said I'd have to cart them down the ladders in me hod" I'll leave the fun part for the interested reader to find, as a paraphrased retelling doesn't do it justice. A quick Google search brings up the lyrics and the YouTube video.

-

Those marks make it look like a rolled product form to me, too.

-

rebrazing repaired crack in cast steel?

Chris Williams replied to streetcore's topic in Welder's beginers course

Sorry, I took it out of a Google link and must have missed some of the Google additions. Thanks for posting the good version. -

rebrazing repaired crack in cast steel?

Chris Williams replied to streetcore's topic in Welder's beginers course

That one does not have any fluorine compounds, so I say it is a good choice for a general braze flux. Keep away from the ones containing fluorine compounds unless you know exactly why you need it, and have good enough ventilation (1st) and PPE (2nd, and necessary but no substitute for active ventilation) where you and others around won't be breathing it. Keep in mind where the vented stuff goes, too. https://www.hotmaxtorches.com/download/msds/24000%20Brazing%20Flux%20Powder%20MSDS.pdf -

The blade says "for stone," which is inclusive of granite. Thomas was simply pointing out the inconsistent callout of slate and marble, which are also included in "stone" and do not require a redundant mention. We are not suggesting worry.

-

It's just marketing for the not-prone-to-thinking-for-oneself customer that bought slate or marble and now wants a means of cutting it, but can only find this "concrete, tile, brick, stone, and masonry" blade.

-

Anvil resurfacing ??

Chris Williams replied to Mr. Pushups's topic in Repairing and Modification to Anvils

Malleable iron and ductile iron will behave in similar ways for an end user. The biggest difference is in making them. You will typically see ductile iron produced nowadays, based on the very long (read expensive) heat treatment required to manufacture malleable iron. You can find more detailed and nuanced information with a simple online search.