-

Posts

155 -

Joined

-

Last visited

About Tommie Hockett

Profile Information

-

Gender

Male

-

Location

Callisburg Texas

-

Interests

wood working, rifle building, reloading ammunition, homesteading, and blacksmithing

Recent Profile Visitors

-

We dont have a high predator load here. But I think raising them in tractors help also with the daily moves. It takes a night or two for the coons and what not to figure out how to get into something. So if you move it every day it becomes a new structure to them and they have to work all over again to figure out the weak points. Mobility is key. Frosty. I'm not sure if you dropped off in the middle we had like 3 of them going haha. Just hadn't heard from you in awhile.

-

Howdy guys long time no talk. But yall mention chickens and I come a runnin'. Anyway the video is flawed in many ways, however having said that chickens are profitable. Even when you factor in time and everything else. There are things that can be done like bulk feed buying and supplementing feed from things that require less than 5 minutes a day at your farm. Also the things she talks about with infrastructure are slightly flawed. Just like a forge or a power hammer you don't factor the cost of it into the first flock... or project that you make. You have to figure in a schedule to make it pay for itself. It will cost money up front but over the course of 2 to 5 years it will pay for itself. I think it is called a depreciation schedule, but don't quote me on that. Also them being profitable is a scale situation if you only have a flock of 10 or 15 that falls into the survival/pet range. Anyway sorry for the tangent I would break it down further but then the virus thread would become a chicken profitability thread haha. Yall have a blessed one. Frosty where did you run off to? Aint heard from you in awhile

-

That sucks man but as the wife said we are praying for you. I remember when I was about 16 and all of cooke, grayson and Montague county was ablaze. It got so bad that it didnt even get dark at night we thought we were going to have to evacuate but thankfully they got it put out in time. But no fires here in a loong time. And just as the wife said you would be most welcome, Im no blacksmith but I can talk your ear off about building things and farming.

-

I have a mini mill from Grainger. It is great for a little DIY milling but it is a pita, you have to nail a 2x12 to the log for the chainsaw to have a track then for the next cut you have to pull the nails measure again and renail. I would love to have an alaskan mill or a good portable bandsaw mill. I saw plans for a bandsaw mill once that used tires as the rollers, the most expensove thing was the motor. It seemed a bit dicey though.

-

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Its been a minute but I am nearly done with the repairs. I have the roof on amd all the shade cloth and tarping and mesh on it. I had planned on putting an arch on the top with my goat panels. But it just wasn't working the way I wanted it to. About the only way I could find to get it rigid enough was to make the arch 4 foot taller than the back end, and it is 5 foot tall. So I really didn't want that tall of a structure. I ended up just laying the panels flat on top and sturdying the back end up with some 1inch schedule 40 pipe. So now all I have left is figuring out roosts. I need about 30 feet of roosts in here so if anyone has any suggestions that would be awesome. Anyway it is sturdy and the roof holds 135 lbs. You may ask how do you know this said roof holds that, I answer you with check out the pictures haha -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Das, my dad and I are working on a day range system for his birds. He doesn't do the tractors either but his is a time constraint. Charles, we are probably going to try some of the cornish cross but the ones I really want to try are the transylvanian naked necks. They are supposed to be some of the best tasting chicken in the world. They grow out a bit slower but if they live up to their reputation... poor word choice then 12 weeks will be worth it Look forward to showing you around Randy. I'm the same way. Once I get home from work I hate leaving the house to go anywhere. -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

That is it exactly. No too much of a problem with predators it is more of a regenerative farming mind set. If you let them free range they will always have their favorite dust bath hole and their favorite scratching hole and so on. Keeping them in the tractor ensures that they get fresh grass and bugs every day plus I get to determine where I want the fertilizer at. And just by the way yard birds love porches. They really like to poop on them haha that is another reason why tractor is a better setup than free range. If you have a minute to do some studying you should look up Joel Salatin or John Suskovich. Oh and maybe Grady Pheelan he doesn't live to far from us in Texas. He makes a thing called a prairie schooner. Think chicken tractor but massive I think it holds like 6 or 8 hundred birds but that is broilers. We plan to start up a pastured broiler operation in the spring using a modified salatin tractor -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Nope sitting at the man camp off of 81 at the moment. Gonna do some work for XTO tomorrow near weatherford and then I will be south bound and down headed back home. Randy I have a buck and I will even give him to you if you make the drive all the way from Alabama David as Randy said 2x4 is a good size but if you do put some stuff on the bottom I found some black plastic mesh stuff from tractor supply that seems to work good and it was cheap too so thats a bonus -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

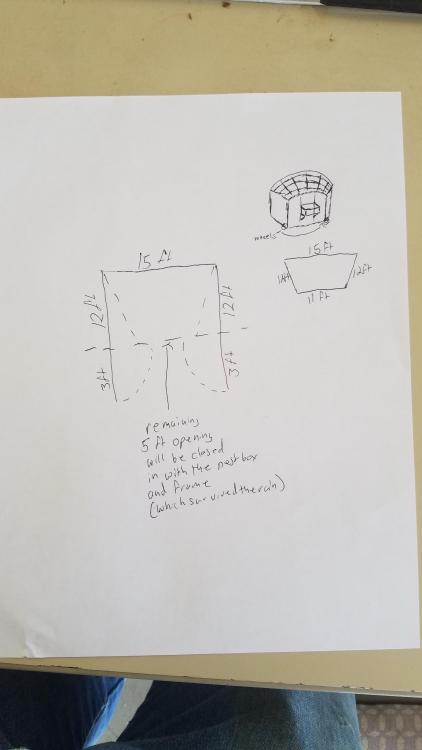

Allrighty then I'm back. Although I am currently in El Reno Ok at the moment so no work will get done for a few days but on the upside I have full signal. Anyway so I think I have an idea on the roof using arched panels. I already have the goat and sheep variety on hand. Also as far as tarping goes I have a llllllooootttt of that on hand as well. I work at a place that makes reinforced vinyl containments for the oil fields. So any time there is a scrap piece they let me take it home. And scraps for them can be huge. Also I have a lot of 70% shade cloth on hand. There is a golf tournament down by dallas that gives the stuff away every year, they post it on craigs list.... Hello my name is Tommie and I have a hoarding problem. So anyway i am going to measure the widest end of the tractor and cut the panel about a foot longer than that so it will arch when I put it in. Hold on for pictures. First 2 pictures are of the completed one. Still needs a few things but should be ok until the weekend. The next picture is of the collapsed one. It doesnt look quite as bad as I thought it would. 80% of it was salvageable. And the next one is what I am planning to do to fix it if you can make heads or tales out of my drawing. Frosty please go easy I can read blueprints but I'm not so great at drawing them haha Howdy David I see that you are in Texas!!! As Frosty said there are a lot of smart people on here. And they have an answer for just about anything you could ask. -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Well I am working with the existing frame. It was 15x15. So I cut all the bad stuff off. I have a slope of 1 ft it will be 15 ft wide on the tall side and 12ft long on the side. And I have enough usable stuff to make it 11 ft on the back side. I wish I could get a dadgum picture to upload so I could draw it out. Not sure how many panels I have... 3 I think but I am going to have to tear down one of the old tractors to find out for sure. I am going to strengthen it with square tubing. -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Yep I was thinking the exact same thing. Maybe a little different... How would you do the roof. I do have some goat panels, they are like cattle panels but smaller squares. Maybe I could put those on top with some bracing... Frosty I am telling you it was amazing, epic and awesome all rolled into one. However I didn't get them into the right spot to work properly. Anyway we got the other one completed... ish there is more work to be done on it like adding more support for the tarp and making real nest boxes. They have five gallon buckets to lay in at the moment which works but its hard to gather eggs. You have to crawl under the roosts to get to them..... pics or it didn't happen So I can't get pictures to upload signal is spotty today will work on that here in a bit -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Yeah the tent pole in the middle came after it collapsed. I tried to make a sloping roof but there just wasn't enough support so I added an awesome drainage system that apparently didn't work. Charles your tractors look a lot like my old ones. Mine had more wood on them though and were rediculously hard to move. Here is a pic of the one before the collapse and drainage system. -

Welding up a new chicken tractor

Tommie Hockett replied to Tommie Hockett's topic in Welding/Fab General Discussion

Ha! Well it depends on how many chickens you got. . The reason they call it a tractor is because the chickens disturb the top inch or two of soil and they fertilize it. You are supposed to move it every day, but my other one was big enough that I only had to move it every other day. Well here is the progress so for. Hopefully these pictures aren't too large, I don't know how to resize. Just dont zoom in on the welds and excuse the mess haha -

Well we woke up this morning to the awesome sound of rain! So I quickly donned my rain gear and ran out to check on the animals and button the pens down so the animals weren't getting pelted. Anyway so I had no more came inside and poured a cup of coffee when Chellie told me there was a chicken out. So I went and looked and the rain had collected on the roof of my 2 month old chicken tractor that my step son and I had welded up out of 1/2 emt conduit, so much so that it collapsed.... so we pulled it back up with my truck. The truck cannot move until I get another one built hahaha. So anyway there are a few upsides to this one we got some much needed rain. Two I was home when this happened. Three I have a bunch of schedule 40 1.5 inch pipe that was for a different project but got repurposed for this one. So today I made record time and completely welded up a new chicken tractor the only thing left is the wheels and to put the tarp and wire on it. This one will be a tad bit smaller at 15ft x 10ft. These my friends are the joys of farm life and I got to tell yall I wouldn't want it any other way. Oh and another thing all of our welds with the exception of 2 held up!!! The water was just too much for the conduit to hold. I will post pictures tomorrow. I would take some now but its dark and you wouldn't be able to see much.

-

No we have plenty of that growing around here. It is a pain to mill though. We call it bois d'arc (bodark) around here. This stuff is actually orange colored. I will see if I can look it up and I will let yall know Padouk is the name of it.african wood. Starts out orange then dulls to a darker brown. Kinda like bodark starts out highlighter yellow then goes brown with age.