-

Posts

19,293 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

That's about $165 today.

-

In an IFI context, it makes more sense to add a comment to a thread you want to resurrect than it does to post a link to it. The former gets the original conversation going again, while the latter can create a separate discussion.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

The question isn't how we survived childhood; it's how many didn't. See Abraham Wald and the bullet hole map. -

I’ve made a couple of nice chisels from truck leaf spring after splitting it lengthwise with a handled hot cut and the treadle hammer.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I believe powdered lime sulfur is the standard mercury spill cleanup, but I could be wrong. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Also, cut away one side of my grinder station and welded in a frame made from an old bed rail: To hold a recently acquired tackle box: Which in turn holds supplies for the buffer: -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

A few estate sale goodies; $10 total. The tackle box is especially fortuitous, as I have a storage need for which none of my other spare toolboxes were the right size.

-

When I was attending the college where I currently work, it was surrounded by cornfields. The same fields are still there, but nowadays they rotate between corn and soybeans.

-

Were the yellow jackets all holding the same chainsaw, or did they each have their own?

-

I'm one of those weird hybrids that use an iPhone and a PC, so I can't take advantage of the app's capacity for sharing between iOS devices. There is a cloud-based sharing option that I could use to edit phone uploads on my laptop, but I'm too cheap to spring for a subscription that I don't really need. Not at all! Just scan the books where they are, and it'll be easier to locate a particular volume within the chaos!

-

$4.99. There’s a field for “Physical location”, so you could number your boxes and add those numbers to each book’s record.

-

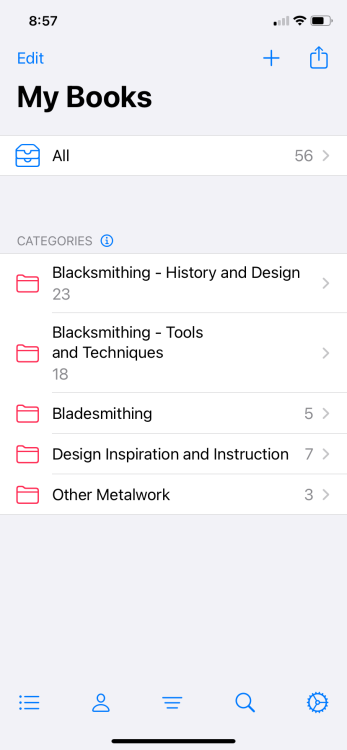

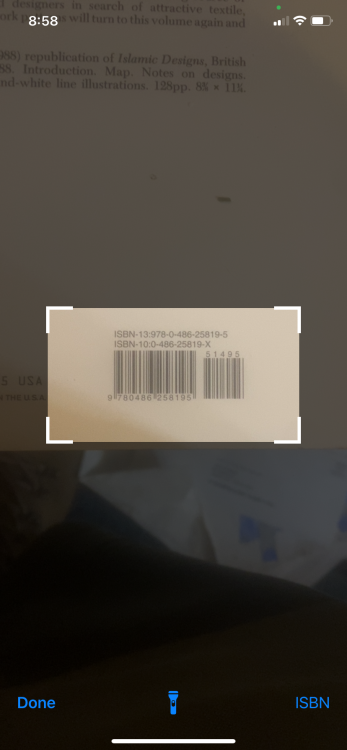

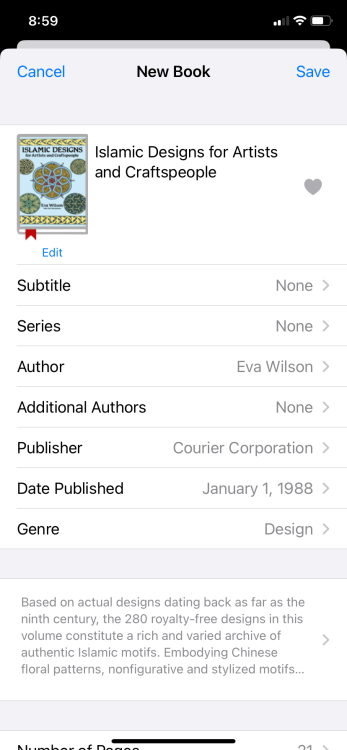

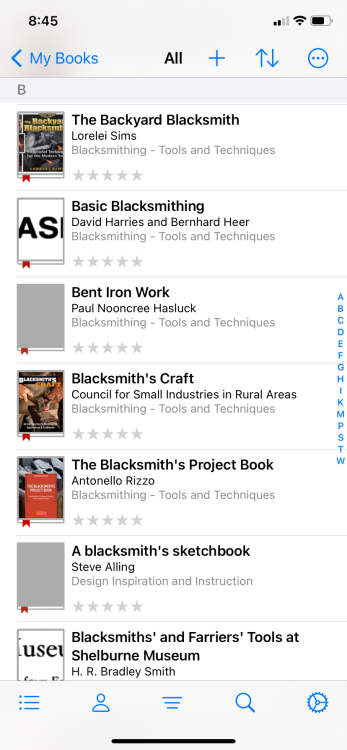

My smithing library has expanded beyond the point where I can remember all of the titles on my shelves. This is occasionally a problem if I’m browsing online or looking in a used book store, and a couple of times, I’ve ended up buying duplicates. In looking for a solution, I discovered a rather good cataloging app called Book Buddy, which comes in a free version and a paid version. These have the same features; the only difference is that the free version has room for a mere 50 volumes, while the paid version (a one-time fee, not a subscription) allows an unlimited number. The features I’ve used most so far are the categorization function, which lets you decide how to organize your books: And the barcode scanner, which lets you quickly identify books by ISBN: Without having to type in all their individual details: For books that don’t have a barcode, you can scan or type in the ISBN, and for older volumes that predate the ISBN system or that were published privately, you can enter the details manually. I haven’t yet tried it with periodicals (such as The Anvil’s Ting or The Hammer’s Blow), but I’ll keep you all posted on how that goes.

-

Is this slag?

JHCC replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

While you're at it, check out the Hopewell Furnace National Historical Site: https://www.nps.gov/hofu/index.htm. They've also got a pretty well kitted out blacksmith shop. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Found a nice chunk of 1” diameter shaft lurking at the bottom of the pile, so it looks like I’ll be going this route. -

Hobby, hobbier, hobbiest…. (Not to mention hobbits.)

-

That was the original plan, but you got turned around.

-

Those calipers and dividers often have good resale value. I once got a big box of these from a Facebook Marketplace listing, and they did very well on my tailgating table at Quad-State.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

That's the great thing about iteration: when you push yourself to make each new version better than the one before, not only is that new version an improvement on the previous one, but your skills and perceptions are getting better as well. This in turn prepares you to make the next version better, and the one after that, and the one after that. Eventually, you'll find that those incremental improvements have resulted not only in better finished objects, but greater ability on your part. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I’m glad it worked out. Much improved! We only have dogs. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes, it is an industry-standard kitchen sink. It's also an IFI-recommended *salvaged* kitchen sink. Also, in the established tradition of reusing everything, the sand was previously the fill of my old side-blast coal forge. -

If you haven't read the Recommendations for Working with Anthracite post, do.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

When your press is a little light and you can’t bolt it to the floor, but you DO have an old sink, two buckets, a couple of barbell plates, and a wheelbarrow full of sand… -

A neighbor was giving away a bunch of stuff, and I nabbed an old slide rule. Always wanted to give one a try.