J.P. Hall

Members-

Posts

58 -

Joined

-

Last visited

Profile Information

-

Location

Orange County, NY

Recent Profile Visitors

1,102 profile views

-

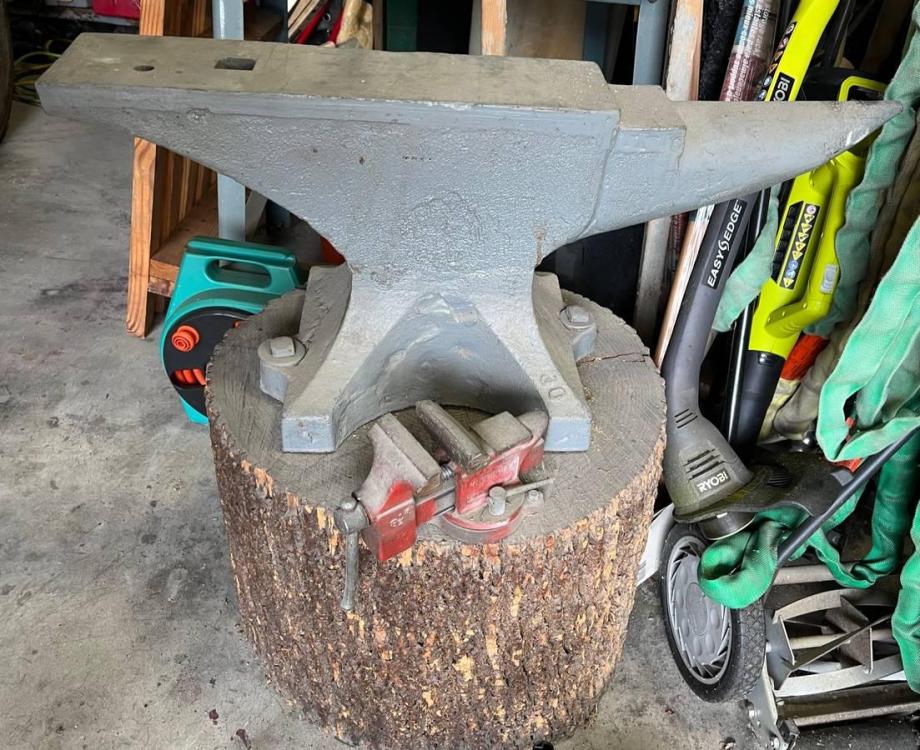

I was hoping they would, but they took it off the stump when I got there. I certainly think so. I've got to dress it up just a bit, maybe de-bark and char/oil the stump, and then make a sleeve for the hardy and then it'll be in regular service

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

I sure did. They had a bobcat to load it into a pickup (it was at a place that carves headstones-- I should have asked if they had any scrap I could use as a surface plate), and I used some strategic maneuvering and scooching to get it unloaded and in its new home

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Well, to my surprise it was still there when I went to check it out. It bounced a ball pein just fine despite a coat of paint to absorb a bit of the impact. I love Fishers for their lack of ring, but I was very happy to find out that one of this size doesn't even have much of a "clang" when hitting the horn or tail like some of the lighter ones do.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

I'm hoping to take a look at it this weekend. I may radius the chipped portion-- I've had a crisp-edged anvil for a while and would like to have a nice radius for drawing out, but I'll still hold off on it for a while to be sure. If the vise comes with it then it's an even better value.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Here is a 300-pounder that I think may be 1950s due to "30" being the only visible markings. I think the seller is reasonable asking 3.25/lb even with the chipped edge, but I'd like to hear others' thoughts as well.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

J.P. Hall started following Fluidized Sand Bath for heat treatment

-

Fluidized Sand Bath for heat treatment

J.P. Hall replied to JHCC's topic in Heat Treating Knives, Blades etc

I've been toying with the idea of making one for quite a while. I've been using a PID-controlled gas forge for heat treating and its biggest limitation is evenness of heat. I was thinking of having a stand that could tilt it vertical to accept the tube. A dedicated setup would obviously be ideal, but I'd like it to be something that other people could build for a modular setup with their own forge. I'm imagining a coil of small diameter tube with small holes drilled in it sitting in the base of the main sand tube. A no-weld version would be great for both testing and maintenance, as well as minimal barrier to entry. The main issue would be passing a small tube into the larger one while maintaining a seal, not unlike a bulkhead or tank fitting for pipe. -

I was gifted a couple bars of wrought iron recently. I tried a break test and it looked clean enough that I was convinced they were actually mild steel. I would have taken then pieces anyway because I could have used the 3/4" square stock, but it felt unusually soft and it hot cut like butter. A spark test showed few sparks with little bursting compared to known mild steel (and high carbon as a sanity check), and a long etch in strong acid showed the telltale grain, albeit much finer than the few samples of wrought I've seen.

-

I'll second Daswulf's comment of having some sort of fuel containment. I prefer angle iron or firebrick for ease of adjustment. For bituminous and charcoal I use a barrier to contain the fire and conserve fuel; for anthracite (and if I used coke) I use it just to keep fuel on the table because the fire doesn't spread much from the air source.

-

Weatherproofing a wood stand?

J.P. Hall replied to J.P. Hall's topic in Stands for Anvils, Swage Blocks, etc

I like that idea quite a bit. I was thinking a generally thin oil like mineral or regular linseed would soak up better, but it would probably drop out almost as fast as it soaked in. I think I'll go with a thinned BLO like you suggested, and maybe something thicker to seal the top. I also really like the nuts idea. I could probably use them after just to keep it out of any puddles too (or pea gravel or whatever) not as absorbent as sand, but small enough to help settle and even out unevenness between the stump and stone, and not too compressible. -

Weatherproofing a wood stand?

J.P. Hall replied to J.P. Hall's topic in Stands for Anvils, Swage Blocks, etc

I'm not too concerned about the footing. It's on a flat stone about 6ft wide and 4-6" thick on top of compacted soil and pea gravel. My main worry is rainwater puddling on the stone and getting soaked through the base of the oak. -

Weatherproofing a wood stand?

J.P. Hall replied to J.P. Hall's topic in Stands for Anvils, Swage Blocks, etc

Something else I've seen is "shou sugi ban", scorching wood to prevent rotting and deter insects in Japanese timber framing and siding. I'm hoping that would help in addition to a sealant. I'll steer clear of anything too harsh because there's a fair amount of groundwater that flows through my area and I'd hate to leach into it. I looked into the wood glue sealant a bit more and it seems pretty effective. It might be easier to seal over the large pores than to saturate everything with oil It's sitting on a pretty hefty paving stone and I leave a tarp on the anvil so there isn't a ton at stake. The old stand made from 4x4s has held up decently over a year or two. -

I recently came into possession of a large section of oak trunk to use as an anvil stand. I'm not sure of the species but it's definitely not white oak, so it will most likely suck up water from my outdoor work area. What would be the best option to protect it from the elements? I'm debating between linseed oil, paint, and end grain sealer used for drying lumber (some people even seal end grain with wood glue). The diameter of the trunk is 27" at the narrowest, so I'll have fresh dry wood once I trim it down a bit. I'm thinking 16-18" square for my 130lb Fisher.

-

Great info. I have a natural coticule that I use for sharpening, if it breaks or becomes unusable for that then I may try using it for polishing.

-

Beautiful polish. I'm sure you can't get *exactly* the same effect with conventional abrasives, but do you think something more cost effective like EDM stones could give something similar (provided they come in high enough grits)? I'm also curious if this is purely polish or if you used any etching.

-

Camp knife -- 80CrV2, Ipe, and brass -- criticism welcome

J.P. Hall replied to J.P. Hall's topic in Knife Making

Thanks guys. Slag, the thickness was necessary because the hole on the female bolt doesn't extend close enough to the head. I'm going to find or make something that will give proper clearance. I have a hard time buffing wood with compound. I may be using too much, but it usually seems to smear some residue. I've tried using less, but it doesn't seem to be enough to really do anything. I'm fairly certain the wood is Ipe. It's a tropical hardwood used in similar applications as teak. Got it from the scrap bin at a local stair company. I did notice a small crack in the handle near the bolster, probably from the chop test. If the end cap isn't really cranked down, there is a small bit of vertical play at the bolster. It's also expanded slightly hirizontally just enough to feel relative to the bolster. There isn't a visible step at all but it irks me. I've since bedded the tang, and will most likely do a full-on epoxy job for the next one. excessive spacing removed