-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Forging Carver

-

Yeah right now the anvil works just fine. The only good edges I got are behind the hardy hole. It works for now, and I definetly am never getting rid of it. It is the perfect portable anvil.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Nah I haven't been spreading any rumors. I wouldn't do that to you. I just got a bit excited when I heard Alaska.

-

Here's my fisher. It is a great anvil, but has really poor edges and a bad hardy hole. There is also nothing left as a step either. Hopefully I will find another fisher in better shape some time. And it looks like the picture is going to be upside down

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Also, I have watched this show and read a thread about why they don't temper their knives. I know for a fact that they don't temper their knives becuase of episode 1 of season 2. They judges used a file to test and see if the guys blade was hard. Now if he tempered the blade, then that test wouldn't work. I guess they could do it in the handle stage, but why wouldn't they show just a glimpse of it then? This has really been making me wonder. your facts are wrong, they temper the blades overnight, off camera. You seem to have developed a habit of posting nonsense without knowledge of the subject.

-

Alright. Glad you mentioned that. I had no idea flares were used for different purposes. I read Wayne's page and it said to attach the flare to burner mount. And then read your t burner instructions and you said that you may or may not need a flare. I was a bit confused, but I contacted Wayne and he should help. Thank you for putting up with my probobly dumb questions. Don't even say there is no such thing as a dumb question, because you will regret saying it . Thanks

-

Yeah I agree. I kind of got into the thing a bit too much. But I also have to say, who wouldn't want a nice lookin hammer? If your willing to put in the time, why not? I know you have heard this a million times from me, but a nice looking gamer will make me forge better. You guys can disagree all you want. The prettiness builds confidence and makes you forge with much more confidence. Somehow it works for me. Strange. Just like how I can't lift up my pinky without my ring finger stuck up. There's is a whole bunch more that would leave you guys puzzled. We will save that for another time . Thanks everyone on this thread for the help

-

Second Gas Forge Build-Used Half a Muffler

Forging Carver replied to norrin_radd's topic in Gas Forges

Oh nice, it is about the same size of a freon bottle. At first I thought these dimensions were going to be too small, but then I realized that I only do small stuff. Bottle openers, occasional knife, tools, and small pocket stuff. I think when my forge is finished, I will be very satisfied with it. I wish you the best of luck with your new forge and smithing! -

Alright thank you. I am still a bit confused, but I will read around a bit more and hopefully find u destined a bit more. thanks

-

I would call it a wrought iron bench with oak seat.

-

Second Gas Forge Build-Used Half a Muffler

Forging Carver replied to norrin_radd's topic in Gas Forges

Nice forge! I saw that video a few days ago. You did a pretty good job at it! What's the diameter of a muffler? -

I will tell you what I know. So for punches, chisels, drifts, etc. that will be used on hot steel, H13 is a real good choice. The only problem is that I hear guys say it is a hard steel to work with for the absolute beginner. I can't say for sure, but I think that as long as you forge at the right temperature you should be okay. A good option is to use coil spring off a car. I am waiting for my dads friend to take off a coil off an abulance within the next couple weeks. For hardy tools, truck axil should do the trick. You don't need any fancy steel for this since they will be used to manipulate hot steel. I believe that my hot cut is medium carbon steel. I could be mistaken though. Tongs can be made from plain old mild steel. You don't need anything fancy for these since all they are doing is holding your steel. As far as hammers go, I am pretty sure there is a whole bunch of different types of steel you can use. Truck axils, 1095, 4140, and a whole bunch more will work. I hope this helps you out some.

-

That's is a real nice knife. I love the blade shape too! It seems like a perfect desert knife in that it can chop up branches and maybe a snake, and can also serve as protection. Cool blade!

-

So what happened? Episode one was aired two days ago. Did your buddy win?

-

Whoa, I believe anchorage is close to Frosty, or at least I heard Frosty say he gets forge stuff there. You should contact Frosty and see if you guys can meet up one day. Frosty is a wealth full of knowledge. If I were close enough to him, I would definetly go visit him for the day and learn a while bunch from him. Give him a pm and see if you can meet up! Hope this helps you a bunch.

-

Wait was the Thomas power anvil finding technique an actual blueprint? For me it seems once you find an anvil, you start popping up along them tons of times. It just so happens that after I bought my anvil, one was sitting in my local hardware store. I still got to make an offer on that, but my cash supply just got drained from that freon forge. Anyways, then I find mini anvils too. Paper weight sized. Then just the other day, I found a railroad spike anvil. The thing is that I'm not even looking for these. They just pop up out of no where. I swear, that railroad spike anvil was not there when I was first in the room. I looked around a bit and right when I was about to leave I jerked my head and the anvil appeared in the corner of my eye. Now of course I am looking for a post vise and can't find one. I am sure once I do, they will pop up out of no where too! Thomas Powers you are crazy too. Crazy in a good way. You know your anvils, that's for sure. You can get a pretty good idea of the brand anvil just by looking at the shape of the anvil. I hope one day I will be able to do that!

-

candle cup tutorial

Forging Carver replied to FieryFurnace's topic in Blacksmithing, General Discussion

Great blue print! -

Alright. The nose punch I figured out the dimensions, and now I will figure out the eye punches dimensions tommorow. Just incase some of you were wondering, the nose punch should taper down to about 1/8" (3mm) before you start to file it. This is for the usual bottle opener sized horse head. Of course you can give or take a tad bit, but you don't want it too large or too small. I will let you guys know a good size for the eye punch tommorow. Thanks for the help

-

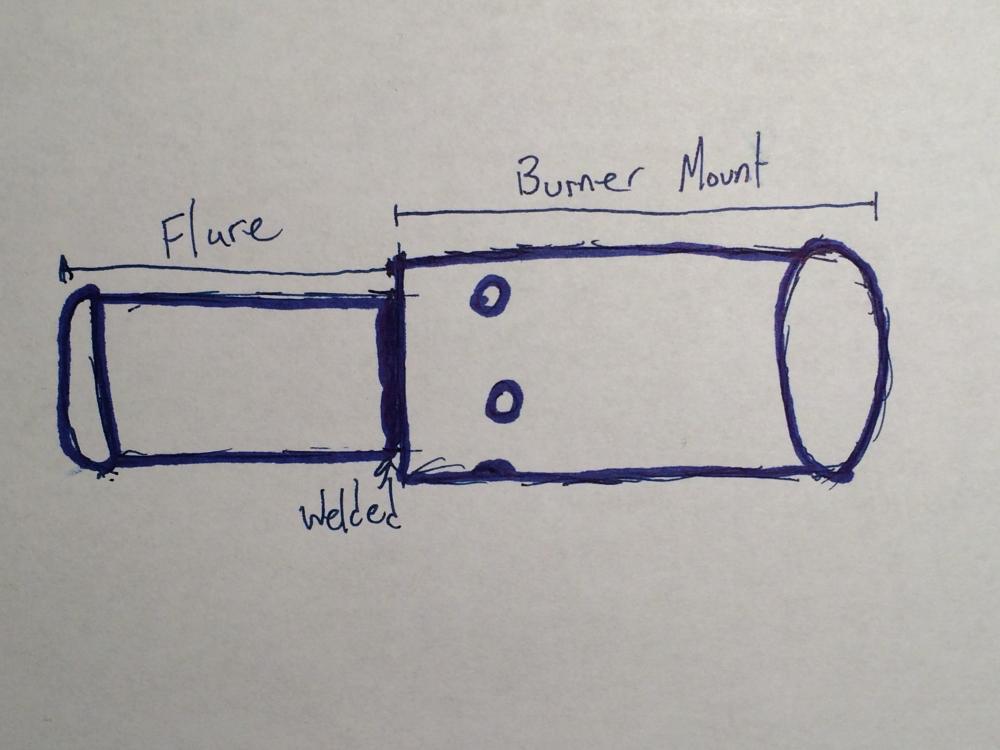

Hi I have been reading the gas forge section so much that my eyes couldn't handle the light of my computer screen. I have been looking for an answer to a question I have on flares. So here it is. Well actually I will tell you what I think is right and you guys can correct me. So I believe that the flare is welded to your burner mount. The burner mount stays out of the forge, and the flare goes into the lining but stops right before the chamber. I was looking at Wayne coes propane forge and it looks like he cuts the burner mount on a 45? It is either this or some how he drills a hole in the tank so that the burner mount and flare go in at an angle. I know that having the burner on an angle like this creates a more even hear in the forge. Sorry if this sounds confusing, but if one of you can clear this up, it would be greatly appreciated. Here's a diagram of what I drew on how I think the burner and flare should look like. Let me know if I am wrong. Thanks so much

-

Ok thanks for the help everyone. Glenn that is a good idea. The size horse head I am going after is bottle opener size. thanks

-

Look up hot iron art on YouTube and look through his videos for a railroad spike snake. I think it was in his 1500 views video.

-

help build a safe propane gas forge hobby works

Forging Carver replied to angiolino's topic in Gas Forges

I would recommend making a real gas forge either from a freon bottle or propane bottle. It would be much more efficient and safer. That's what I am doing, building my self a freon bottle forge. Go to waynecoeartistblacksmith.com and go to forge supplies. From there you can get all the materials you need and read his PDF on making a gas forge. Read around on the gas forge section of this forum for good tips and safety. Have fun! -

Alright so I think I got the general idea of what to do for both. I am just unsure what the dimensions should be. Can any of you who learned how to make these tools tell me what size the make e tip of each taper for the Jose and eye chisels? Also, it looks like brazeal makes his eye punch a little bit oval, but not too much. Also, can you tell me what size round punch you use to make the divot in the eye punch? Thank you so much. If I remember I think that you made these tools Ethan Harty. Hopefully you see this post. Thanks

-

Thanks for the help. No way! I asked Lea how he would make one and he made a video for me! I never subscribed to him for some odd reason. Thanks!

-

Hi, I have seen Brian brazeals video on making a horse head. It seems pretty self explanatory to me. My only issue is trying to figure out how to make the eye punch and nose punch. Can one of you tell me the steps in making these? Giving dimensions throughout in your instructions will help me a lot if you would be so nice to give them. I have spent a whole lot of time trying to figure this out. Knowing me I am overthinking and it is going to be something really simple. Thanks you so much