-

Posts

269 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ethan the blacksmith

-

How to forge a rounding hammer(video)

Ethan the blacksmith replied to Ethan the blacksmith's topic in Hand Hammers

Were do you get such big ball bearings? -

Welcome to the forum! in my opinion that anvil is in exceptional shape!

-

How to forge a rounding hammer(video)

Ethan the blacksmith replied to Ethan the blacksmith's topic in Hand Hammers

Thanks for the reply! from what I know, not Many people even know what a 3" fuller is! They come in very handy for, like you saw in the video, smoothing out the cheeks. They are mostly used for drawing out, like making the business end on a hammer eye punch. -

Well, I must be fancy, mine is made from half of a old wooden wine barrel. It works really well, and holds lots of water.

-

Hello everyone! I made a video for all the people that are wanting to forge a rounding hammer, like what Brian brazeal makes. The info in this video is gathered from my own experience, and my tools to make tools class in England with Alec steel. this quiet a long video, so I would recommend you watch the video at 1.25 times normall speed. hope you all enjoy the video! https://m.youtube.com/watch?v=ISUsgcxEtZM

-

striking anvil

Ethan the blacksmith replied to Ethan the blacksmith's topic in Anvils, Swage Blocks, and Mandrels

Sorry for my ignorance, but why what is broaching and EDM? -

Drawing out metal with 2 flat faces is very in-effective. You need to reduce your surface area contact, creating more pounds per square inch! an easy way to do this is to draw out over the horn with a round faced hammer, such as a rounding hammer. If you don't have a rounding hammer, take an angle grinder to the face of a hammer. You could use brazeal/hofi tecneque of drawing over the edge, but if you are a beginner, I would not recommend that. Keep your steel hot and use the biggest hammer you can use! Forge on...

-

Thank you all very much for the replies, I will be doing some more research!

-

striking anvil

Ethan the blacksmith replied to Ethan the blacksmith's topic in Anvils, Swage Blocks, and Mandrels

Well I should probably make a video about this but anyway... there are two ways of putting in a hardy hole: drill and drift( I have 2 more striking anvils in which I with have to drift) I will probably make a video of all this. the second to get it water jetted, which this one is. now for your other question: I learned the value of a striking anvil for making tools when I went to England. The striking anvil was all we ever used( apart from when we made bottle openers). the advantages of a striking anvil are mostly about the hardy hole. if you have ever hit an anvil on the tail, or horn, you will know it's very loud. Now imagine two strikers, swinging as hard, and. Fast as they can over the hardy hole, not loud at all...... i have seen to many anvils with tails and/or horns Broke of. There is little chance you will break a tail of on a striking anvil, because there is non. lets say you are upsetting something in the hardy hole like a cupping tool, and you have taken multiple heats. This would start to run colors around the hardy hole, loosing some of its temper. Finally, striking anvils are made of mild Steel, so if a striker misses, and hits the anvil, it will sot send a hurdling chunk of steel into somebody's face. so these are most of the advantages I know of for a striking anvil. Hope this helps. ---------------------------------------------------------------------------------------------------------------------------------------------------- frosty, this anvil really needs to be bolded down because it dances all over the place! i will be making a couple of hammers soon, so we will see how it hold up! Ethan -

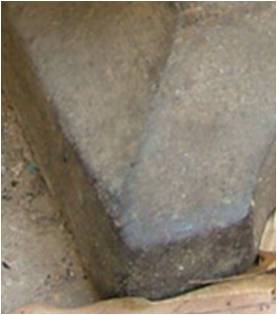

I remember one on my first post on IFI was about advice for building a striking anvil. I have now put that info to good use. I got me 3! for Christmas I got a 3" by 5" by 12" block of steel with a 1" hardy hole in it, and so last night we put a base on it. probably the best striking anvil I have ever seen. I am extremely happy and greatful! I got a couple hammer orders I got to get done, so this will make them a lot easier! at the beginning of December I also got two 2" plates and I drilled a 3/4" hole in them. I will be drifting them soon, and I will post plenty of pics. here are some pics of the anvil.

-

thanks very much mr. D

-

Thanks you for the replies!

-

a late merry Christmas to everyone on I forge iron! I am looking to get belt grinder, not a little knife sharpening one, but hopefully a big industrial one, something with maybe a 4" belt or so. if any one would have a link to a good one, a recommendation, or knows of a brand/maker, it would be greatly appreciated!

-

a good fire pot size in my experience is about 3 inches deep or so and 7-8" by 10-11". I will try to post a picture of my fire pot.

-

Do they call that a dog's head hammer?

-

hello every one! I finally got around do get the photos ready, and I shot a video showing the tools. this was a 6 day class in Norwich, Norfolk, England. and o yes........I would definitely go back, and do it all over again. Alec Steele is a wonderful instructor. Heres the vidhttps://www.youtube.com/watch?v=33hnRA-TZLI I also have some pics! side note: in the video, I forgot to show the drift.

-

moloch 50# hammer, what to look for

Ethan the blacksmith replied to JMarsh's topic in Power Hammers, Treadle Hammers, Olivers

from my VERY limited experience with trip hammers, I have found that if there is to much were in ram guides or other bearings, there will be a bad knock, leading to more wear. if its not that bad, you can simply remove some shims, but if there are non, you would have to build up the part, make a new part, or in the case of babit bearings, re cast them. some one please correct me if I am wrong. Ethan -

frosty, what is the swell at end of the handle for? is it to keep your hammer from flying out of your hand, or simply decoration?

-

what size of coal are you using?

-

new job - safely swinging a hammer?

Ethan the blacksmith replied to Leeknivek's topic in Blacksmithing, General Discussion

here is a good video on swinging hammerhttps://www.youtube.com/watch?v=Z_tLVdaxYyk now, I have only been forging for a few years or so, and I have a lot to learn, but this technique works really good for me.