-

Posts

8 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Williston, Vermont

-

Interests

Rock Climbing, Camping, Hiking, Woodworking, Architecture, NROTC.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

JPVT changed their profile photo

-

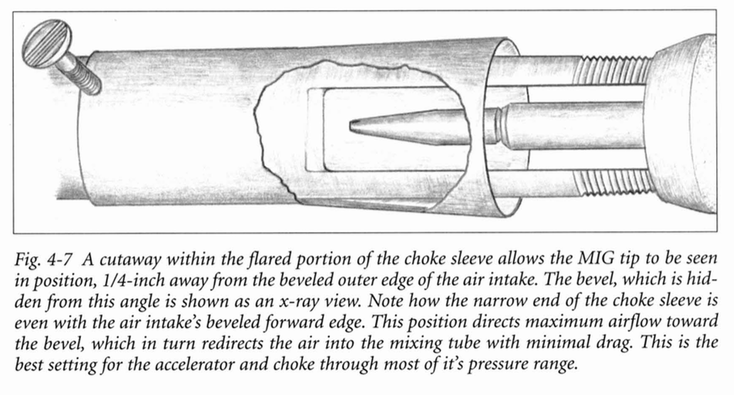

The only *major* change was utilizing a choke that wasn't depicted on Zoeller's site. This choke is based on one found on the school's foundry. The other modification was just for ease of assembly and to ensure (beyond a doubt) that the MIG tip is pointing directly straight. I could understand criticism about the choke mechanism (maybe not getting enough air) but I designed and fabricated this with the help of an experienced engineer. The regulator I'm using is from Hightemptools.

-

I am in the final steps of finishing my propane forge. I have made a burner based off of Zoeller's Sidearm burner, with some small modifications: namely a customized choke and my own take on the MIG tip assembly. I ran the burner for the first time today in my driveway, and I noticed that it sounded very choppy as I added more and more oxygen. I took a short video as I cycled through the choke, watch it here. https://vid.me/nxoS It was sort of windy out, but I don't know if that's what led to the choppy burn. I have more pictures of the burner here on Imgur. This site likes to delete photos from threads. I was running at around 7 PSI through a Marshall Excelsior regulator.

-

What are people using as quench buckets? I'm wary of using (and possibly melting) plastic, and I have no clue just how wide or deep a bucket needs to be to be useful for general forging.

-

Railroad Track Anvil Improvements?

JPVT replied to JPVT's topic in Repairing and Modification to Anvils

What's a good way to secure it in a vertical position that would still allow it to be turned on its side? -

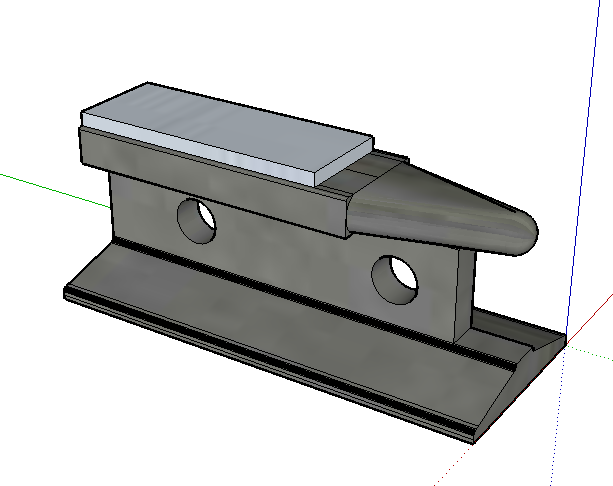

I got 12" of railroad track given to me as a gift, and I intend to make it into an anvil. Now, before y'all start cringing, I understand that RR Track is not the ideal anvil material. But I'm trying to start blacksmithing as part of a project for school, and I want to be show that you don't have to drop hundreds of dollars on an actual London Pattern anvil. That being said, I want to make this piece of rail as useful as possible. I've seen several drawings of RR anvils that are turned on their end; which I don't think is for me. Being very inexperienced at smithing, I'd rather not limit myself to such a small 'whacking surface' like the ones shown Link removed So, in discussion with my shop teacher, I've been looking into welding a piece of steel onto the face of the track, which I have already flattened. This would allow for a stronger piece of steel to become the main surface of my anvil, and also creates a table. See the (badly rendered and not perfectly accurate) image below for what I mean. First- is this a good idea? And if so, what kind of steel should I use? I don't know a ton about metallurgy, and there are a lot of big terms out there like Rockwell C, air-hardening, and other stuff... too complicated for me. Should I use tool steel? If so, will A2 will be sufficient, or should I put out the extra money to get a piece of A500 Steel? Any other suggestions are welcomed. Anvil fire does not allow hot linking to it's site

-

I've been using Michael Porter's Gas Burners for Forges, Furnaces, and Kilns as plans to build my gas forge and burner. The plans recommend I use a Tweco .030 or .035 inch MIG welding contact tip, 1-1/2-inch long. I have no experience with these parts, and have no idea what the importance is of the length, the taper, etc, and I've been unable to find this part anywhere. The drawings in my plans show a tapered MIG tip (shown in attachment), but I've had difficulty finding anyone who carries any contact tips with tapers. Most parts I've been able to find have a rounded end. Does the overall length of the MIG tip, the inside diameter, and the taper on the end affect performance? If not, I'll just buy one that I can find readily, and not have to go searching for this exact piece.

-

I know this is probably an over-posted topic, but I've been looking for an answer for quite a while and I haven't found it. I've seen several pros and cons lists about coal vs. gas stoves. I've seen a lot of the same information, but also a lot of conflicting information. I'm looking to build a mid-size forge to be my first forge. I am a complete novice at blacksmithy. That being said, I've seen some people who say that coal stoves are the way to go for beginners. According to some, because of the versatility and better heat available with a coal forge, that is where all beginners should start. People also say that the larger surface area and ease of welding are major pros that help beginners. However, some people say that because coal forges burn hotter, it's easier to burn your project, it's harder to replicate results, and controlling the fire and the metal is too much for a beginner to handle. There are also obvious health risks. Proponents of gas stoves claim that the forge itself is much easier to operate, it's easy to reach welding temps, it's cleaner, it's harder to burn your steel, and they don't require maintenance. Opponents say that gas stoves are touchy, they don't get as hot as coal, they restrict the beginner's ability to learn how to use the heat, and that gas is much more expensive. I live in Vermont, and I'm fairly certain that both anthracite and bituminous coal are readily available to me. Propane and MAPP are also available. I don't know, however, which will end up being more expensive. TL;DR- I have 3 questions. As a complete novice, should I work with a Coal or Gas forge? Which type of forge will cost me more to operate? (Ignore costs of making the forge)Just in general, what sort of forge will serve me best? (I plan to bladesmith, and probably construction of pieces with welding, brazing, riveting are in my future..)Thanks All! JNP

-

Hello all! My name is Jacob, and I'm a high school student living in the Champlain Valley of Vermont. I've begun the process of designing my future workshop, and I thought I'd make an account here, since I hope to be using this site a lot in the future! I've drawn up designs for both a coal and gas forge, and have the ability to run either, but I've yet to decide which is best for me, as a beginner with shallow pockets. I do have a lovely anvil from the early 1900's already, though! Looking forward to getting started.

- 1 reply

-

- blacksmithing

- first post

-

(and 2 more)

Tagged with: