stevomiller

Members-

Posts

319 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by stevomiller

-

W-2 Anvil Face vs Avg Anvil?

stevomiller replied to Avadon's topic in Anvils, Swage Blocks, and Mandrels

S7 is 180* out from W2. S7 is AIR hardening, W2 on something the size of an anvil is water or brine hardening. Personally, I am having a difficult time understanding how a W2 rod got to full hardiness without subsequent heat treating, and how a 1/4” top layer, whether migged/ tigged/ arced/ forge welded doesn’t end up cracking especially with errant blows if it’s laced on mild steel. The underlying mild will get plastically deformed,. Perhaps we are using different terms, or some such. -

I can’t help too much, except that would rather have a Fisher IF it was in exceptional condition, especially if it’s a blacksmiths pattern and not a farriers pattern. NC are made of heat treated cast ductile iron, not steel, if my memory is correct. That’s not a bad thing, just a thing. The good of it is there’s no weld to break between the face and body, but on the flip side it’s probabl 5-10 points softer on RC scale, if so it could dent easier. The NC is a farrier pattern which has a thin heel and slim waist, so it MIGHT not be as efficient to forge when using say a 2.5-3lb hammer (top end weight wise for a traditional anvil that size. A 70lb cube or “brick” of steel on end would behave nicer yet and could handle heavier forge work, but obviously lacks a horn and hardy hole which both add great utility. I recently bought a cast steel 66lb Italian pattern double horn anvil off EBay for $145 delivered. I’ve only worked on it with a 24oz ball pein so far but it works well for its size. It’s made in China so I can’t say if you bought it’s brother if you’d get as good quality, they can be variable. This one was a nice casting with good heat treat. One like it might allow you to spend less now, and either gett other tools OR set aside saved $$$ for a future bigger anvil. I’ve used a North German pattern 50kg (110 lbs) and the extra weight is nice to have over say a 60/70lbs. A 150lb is nicer yet, and is about the beginning size for shop anvils vs portable or table anvils. You’d still get use out of your small anvil for small projects (horn is narrower) and /or for travel if you ever did a craft fair or rendezvous etc. Bestest Stevo

-

I’d make one more recommendation and that’s to use the same nipple, screwed in as tight as it will be on final assembly, and then chuck it up. Pipe fittings and nipples are notoriously threaded off axis, so using your actual components will ensure that your gas injector will be dead center and on axis with the final assembly.

-

Mikey, I’ve a question concerning the air slots in your Mikeyburner design. I noted you recommend rectangular shape with straight vs radiused ends, and odd vs even number of slots, both to increase air flow/speed and to allow some vortex vs turbulent flow. You recommend chamfering the ends of the slots as well. As a tinkere and equipment engineer these all make sense to me. My question is have you tried also chamfering the long edges of the slots, say an internal chamfer on the left side of each slot, and external on the right sides? I’m wondering if this might induce some more swirl, but hopefully not too much (as I believe you stated this can be overdone). And/or, cut the slots at say 10* (pulled that # out of my gluteus) angle so that they formed a very gentle helix? Thanks for letting me think out loud, even if perhaps they are just the ramblings of a mad man.

-

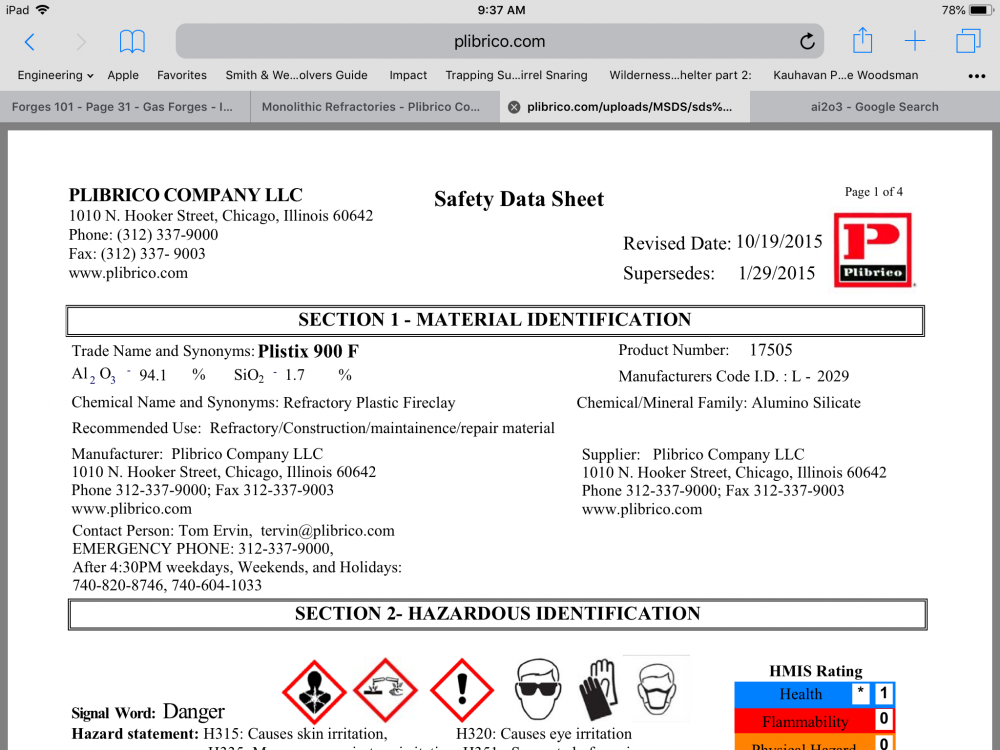

Hi Mike! The Plibrico data sheet I included is for the Plistix 900 that others sell and recommend as the ITC100 alternative. As of yet I don’t know who makes the coating I bought from Hybrid, or what’s in it. I’m hoping the packaging gives me more info when it gets here Monday. Regardless i will post results once I use it, but it’s unfortunate I don’t have any reference or experience to compare it to.

-

Also, I looked up the SDS on Plistix 900, which I’ve read folks here state as having a high zirconium content. Per the SDS, it is 94.1% alumina oxide, 1.7% silicon oxide, remainder unstated. Per this, it can’t be ZrO2, or at least any more than about 4%, but that would mean there’s also no binders, etc.e

-

Folks, i found another IR heat reflective coating at a price 1/2 of the ITC . Hybrid Burners sells it by the pint, it’s called HYB-UV IR reflective coating, claims to reflect up to 98% of the IR energy, said they had a refractory company formulate it for them so they could offer an effective cheaper alternative to ITC. I bought a pint (it’s in transit)and will be using it in my first gasser which I’m building now from a Freon bottle, and 2” 2600* HP 8lb wool (I found a full box at work being thrown out). I have my Kastolite 30 and silica Rigidizer on hand, and a 3/4” burner I’d obtained before I learned from this thread that a quality 1/2” was sufficient. Last item I need to buy k26 bricks for movable doors, and either kiln shelves or materials to make the same for my floor. I’m getting antsy, it’s been over 20 years since I’ve done any smithing, and that was with good old bituminous and charcoal. Anyways, I will post pics when I’m done and anything I learn about the hybrid reflective coating.

-

Peddinghaus replica ?

stevomiller replied to blacksmith-450's topic in Anvils, Swage Blocks, and Mandrels

It’s interesting, North German body with a south German horn to body transition. It does l resemble the Old World Anvils Bulgur. Isn’t Branco in the Czech Republic, or am I “misremembering” again ? Regardless, looks like a useful pattern to me. How big is it? Does it have good rebound, etc? -

Remarkably good small Chinese anvil I picked up for my techs at work to use. I bought it on Ebay for $145 shipped, fully expecting it to be cast iron or low carbon steel, but figuring it would suffice for their usage. It’s an Italian/French pattern, 30kg or 66lbs, 3/4”~ hardy hole opposite the round horn. I usd flap discs on my disc grinder to clean up the horn casting, which was quite orange peely, but the flat face came ground smooth. I originally grabbed a new Johnson USA file to break/radius the edges, only to be met with a screech and now buggered file, hrumppff. Back to flap discs to put an 1/8” radius on most of it, and a greater 1/4” for the first 3.5” on either side nearest the round horn.I don’t have any large bearings to test rebound, but when lightly struck with a small hammer over the sweet spot it will throw it back at you. Both horns ring like the bells of Hades. Long story short, I am NOT submitting an expense report for this purchase because it is coming home to live in my shop to keep my other tools company! For what it’s worth, I’ve had three Chinese steel anvils, as well as an American anvil. I’ve gotten lucky, one 110lb north German pattern was a good casting and harder than wood pecker lips just like this little guy. Second 110lb was a little less, but still a consistent low 50’s on the full face. A friend got same model, complete dog. Either luck of the draw on the alloy they happened to pour that day, or haphazard heat treatment. However, on a good note none of them was porous, again lucky. One of the 110lb went to my dads property, the other to a custom black powder rifle building friend of mine.

-

I have this anvils brother or cousin. I bought mine from an old farmer about 20 miles from where it was made, but know very little as well about it. I did speak to old man Edwards at Edwards Heat Treating in Oakland, he remembered the company and had done some work for them way back. My anvil is in storage now, but I think the markings are identical. The stamped number on mine appeared to be 25460, perhaps the last digit was a C.

-

Spark Test - Need opinions on steel type

stevomiller replied to kraythe's topic in Blacksmithing, General Discussion

I think that it is a pavement breaker ;~)' Do they have a manufacturer's mark on them? -

Mr. Blacksmith, a gate valve will give you finer/more repeatable adjustment of your airflow. And gate valves for water service are rated in excess of 100psi - your blower creates pressures far below this - there won't be a problem.

- 12 replies

-

- forge burner

- propane

-

(and 2 more)

Tagged with:

-

Cost of new Vaughans Anvils in USA!!!!

stevomiller replied to stevomiller's topic in Anvils, Swage Blocks, and Mandrels

The prices I listed are not the price listed if bought directly from Vaughans in England. They are the prices charged by their current US distributor that sells them under their house name of Milwaukee. BTW, I was just window shopping as I have a 150lb cast steel london pattern anvil already. If I were to buy a new anvil I believe I'd buy a Nimba, Refflinghaus or Rat Hole with double horns. -

Holy Cow! I sent an email to Vaughans Hope Works asking if they had an USA distributor, to which they replied that Milwaukee Tool & Equipment was it. I contacted them and received a price list which has just crazy prices! Current prices for those interested (please be seated): 84lb / $1,605 100lb / $1,729 140lb / $2,401 200lb / $3,151 280lb / $4,451 336lb / $5,226 Suffering from a heart attack, Steve

-

Gentlemen, a fellow on Bladeforums just posted these pics of an 125lb anvil that he acquired for $13 at the scrapyard. I had never seen one like this before, at first I thought the face was delaminated and broken but when I looked closer it appears to have been made this way. Thoughts?

-

Yes, those markings mean (loosely) : Send to stevomiller Sorry, nothing of substance to add, but that is a beautiful Fisher.

-

My new Rusty style Power Hammer

stevomiller replied to Mark Wargo New2bs's topic in Power Hammers, Treadle Hammers, Olivers

I'd be interested as well. I have never built a power hammer, but was an equipment engineer and used UHMW for wear plates and guides quite often with exceptional results. It does need rigid backer plates and should never be used as a structural component of the guide system. Best, Steve edit: just reviewed the pic of the ram guide, how do you adjust the guides in the x axis? Are the six bolts for adjusting the guide in the Y axis? What method is used to keep them from loosening? -

You guys are too rough on them. All sorts of good information there; as a matter of fact, it says I can even set myself up in a spare bedroom. I reckon you folks are just jealous because I am going to be a Master Journeyman thing or whatever before you. Oh, and I took their 2 week online brain surgery course. I haven't had one patient die yet from the brain part of it. They did die however from the hammer blow I used to anesthetize them. That's why I'm gonna take the 1 week anesthesia course next ~ my wife is getting tired of me digging up her flowers in the backyard to hide the patients. ;~)

-

Phil, I am sorry for your tremendous loss of a friend and brother. Prayers for you and yours. Steve

-

I will pray for strength, peace and healing for you folks as well. I am sorry that you are going through this trying time. However, it looks like you got some good new in that it is most likely benign ~ awesome! Best wishes Steve

-

Slob, keep after him. Quench is right that the longer you wait the harder it is to recover. Also, if the nerves get compressed enough there can be permanent damage. The surgery would prevent things from getting worse, but then not alleviate the current symptoms. Quenchcrack, maybe we should change your name to "Bioniccrack" ;~). We both need notes from the doctor now before we fly so that they don't think we are smuggling hand grenades in our heinies!

-

How long did they keep you in the hospital? I was there for 5 days. They didn't start my physical therapy for a month. Before that I just walked like you are. It sounds as if you had a better go of it than I did. Maybe it is because of all the extra grinding around I had done, or because of what level on the spine it was at. Thanks for the prayers, Stevo

-

Quenchcrack, I am very happy that you had good results with your surgery. I will continue to pray for your full recovery. Take your pain meds and don't be a hero, follow the DRs orders, and work your butt off in physical therapy. I had the same surgery 3 months ago, except at L5-S1 (one lower than yours). They pretty much removed the whole disc, plus removed a bunch of bony growths where both of the sciatic nerves exit the vertebra. I had instant relief in one leg, and also the burning pain in my lower back. However, the sciatic pain in the other leg initially got even worse. It has now subsided tremendously and I am almost pain free most days. Much like you I hurt my back when I was 22, but didn't get it fixed until I was 41. I believe that God has given us both a new lease on life, at least that is how I am approaching it. God Bless and God Speed, Steve

-

When I have looked at online farm auctions, I see far more smithing equipment in the Canadian listings than I do down here in the states. What it ultimately sells for I do not know, but I have seen some beautiful anvils in these adds. My guess is they will be cheaper than what you would get from Ebay now a days. And Frosty has steered you straight. When I wanted to start I went nuts trying to find the perfect this or that. That is just nuts ~ look at what third world smiths turn out daily with next to nothing and you should become both empowered and encouraged. Best of luck finding what you want and need Steve