-

Posts

807 -

Joined

-

Last visited

-

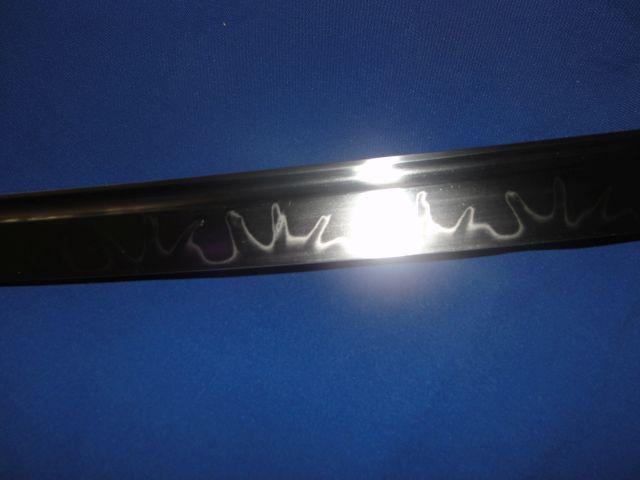

Steve OK since YOU asked... here ya go... 1070 Steel...Kobuse construction.. Gunome Hamon...Deamon theme fittings.. JPH

-

Hello..Since I am still on light duty thank to some rather nasty health problems all I can do is hand work..So here is my latest..just finished the polish.. This is 1070 with a mild steel core...my "3 Brothers" Hamon..Undyed Tiger ray rayskin..bronze dragonfly theme mounts. Turned out better than I thought it would..seems that the undyed Tiger ray rayskin just "brought everything together":... This is current available through my website. JPH

-

Hello: Use a hardy with the same radius as your cross pein..work your way down the bar..make sure you keep it at least a full red heat..flatten on the anvil face once you "cross hatch" the entire bar...I does go quick this way.. JPH..

-

Thos: I am doing the photography at present and started the line drawings..still have a wee bit more work on the crucible stuff as well as pressure and vacuum stabilization as well as bone processing...Just did the Euro composite patterned section as well as most of the equipment..this is going to be a BIG book.. so as soon as I can I will have it to RedInk... JPH

-

Steve: I am stuck in the coop with the other chickens,, H.E. the gov has opened up another NG branch and it looks like I am headed that way once I get the OK from the Drs now that this surgery is done..Time will tell until then I am on admin hold... JPH

-

Steve: Get yourself some 2 x 2 lumber..make up a dozen or so dummy grips and start practicing. I have done so many of these that I don't even need to lay them out any more..I just start cutting and adjust as I go along. I use a 1/2" dia drum on a flex shaft machine..goes quick..takes me about an hour from start to polish depending on material..wood and acrylics go fast as does horn..Ivory when I use it I take my time cause I can burn it and besides..the demand for it has pretty much went away and now I am stuck with a bunch of pre-ban ivory that I am afraid to use for anything... JPH

-

Howdy!! Just finished up this one..This will be on the cover of book IV as well as in the text under grip fluting by hand.. Sword specs: Blade 27" welded from 1070, L-6 and a small amount of meteoric material thrown in for grins and giggles...welded in my "wood grain" pattern.. Grip is custom mixed bowling ball material/acrylic in what I call "petrified wood" colouration. The fittings are phosphor bronze. Sheath is leather, dyed in my "red wine" stain and mounted with a phosphor bronze chape and locket and set with a nice piece of carnelian I hand cut about 20 years ago..The colour matches quite well and the banding in that agate even works with the colouration patterns in the grip.. Overall length is 35".. Not too bad if I say do so myself..I just hope that the Doctors at the VA give me the OK to go back to work on a full time schedule now that I am more or less healed up. What a ride that was.. Gotta keep bacon and beans on the table ya know...the purse is getting a bit empty.. Hope these photos work... This will be posted to my website tomorrow sometime.. JPH

-

Howdy!! Something I just finished tonight..made from a puck of crucible damask..didn't turn out bad at all.. MAJOR learning curve on this stuff...all that C plays with your brain as far as working goes... approx 175 pts C and trace amounts of V and Cr added as crystal starters. Heat treating was also interesting..cracked one figuring it out..This one worked.. Going in book IV..will be listed for sale on my website tomorrow.. Phosphor bronze mounts, bovine ivory grip.. Not an altogether ugly knife at that...Still have to work out a better way to do the etch at the finish.. Love it..you learn more from mistakes that you do successes ..and this stuff...well I learned a LOT!! JPH

-

Something we are working on...

JPH replied to JPH's topic in Smelting, Melting, Foundry, and Casting

howdy!! got on done finally...a PITA in HT but it came out ok if ya ask me.. this one goes in book IV.. JPH -

Something we are working on...

JPH replied to JPH's topic in Smelting, Melting, Foundry, and Casting

Frosty: We have been doing some melts with W in just a small amount...approx 0.015% by weight as a Carbide forming element and well..honestly V works better in the same amount. Either one will require a decent amount of soak time after the initial melt and solidification. We have found that about 10 hours at 1850 F allows for the C t go into solution and then re-arrange around the carbide forming elements into some very nice structures. Still puttering around with this though... JPH -

Something we are working on...

JPH replied to JPH's topic in Smelting, Melting, Foundry, and Casting

Steve: The way I am doing is is a tad bit more involved than what you are doing. Using pure materials and then adding a known amount of C as well as various trace elements like V, W, Mo and Cr to name a few with NO Mn. Mn I have found while it will work is not a friend when it comes to this as it can really darken the finished blade and it can get so dark depending upon the amount in there that it can start to mask the patterning. This is all covered as well as melt times. temp range, cooling rates as well as soaking temp and times. fun fun fun... The reason why I make my own crucibles is cause I am a cheap olde fart and I can do it for a lot less lucre than buying them.. JPH -

Something we are working on...

JPH replied to JPH's topic in Smelting, Melting, Foundry, and Casting

Steve: Really?? That's good news to me..someone else can get crucified for "spilling the beans" for a change.. I have been nailed to a tree far too many times already...Would love to see your melt times and temps as well as how you make your crucibles. I have found that a C content of approx 150 to 175 points with various carbide enhancers like V or even Mo..seems to work best when coupled with a long soak above critic temp after the initial cooling to allow for the C to go into solution to enhance the dendrite formation prior to the initial forging .. Work times are very limited as the working temp range is very narrow or else you wind up with this: A nice crack starting deep in the puck..no fun.. -

Howdy!! Here is a little something my son and I are working on for book IV...just a tease..This will be another "first" for a bladesmithing book..heh heh heh... JPH

-

Thomas: I am finishing up the Japanese section as well as the crucible sections and the grip section..I am also starting the photography and line drawings... work progresses..hopefully this spring.. While the blade came out rather nice//what I am most pleased with is the grip.. I was a bit concerned about the amount of heat that was needed to melt the copal, going from the information I could glean from Roman texts, it did work but the texts really didn't say much about the amount of heat it took..all it said was heated over coals...but it did come out pretty snazzy... JPH

-

FL: Thank you...it took me a while to get that pattern worked out and to get a piece that long but this one worked out pretty well.. JPH