-

Posts

986 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

-

Location

Oregon

Converted

-

Location

Oregon

-

Occupation

Prophet of Doom

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Also who makes the best magnesium filler rods. They look incredibly expensive. and can you use blue or purple tig rods on magnesium?

-

Hello all, I'm looking for alloys that are lighter than Aluminum but still are easy for the average shop to cut, machine, Tig weld, and generally fabricate with. I see that AZ31B is readily accessible for purchase on the web but I've never used it. Is this alloy safe to touch, fabricate, Tig Weld, etc? Are there any precautions I should take? Is it a good alternative to Aluminum? This is for use in the robotics industry. [I always thought Magnesium was toxic to touch or sand and can burn explosively but maybe this is just misinformation I've been led to believe. I'm starting from square one with this material. ] I also saw a company called Allite that has a material called AE70 but can't figure out where to buy it. Was wondering if anyone here has Tig welded with it. Also if there's anything I should know about working with magnesium that would be great. Don't want to poison myself or explode myself (again lol) Thanks,

-

Interesting because I was almost sure they were not snap ring pliers because when you search snap ring pliers they (the modern versions) look nothing like what I have. Mine look like they can hold wire in parallel to the grips. But sure enough when you search "Vintage Antique Snap Ring Pliers" you get some pics of tools that look similar to mine. I'm guessing these are nearing a hundred years old. I'll definitely re-work them to my needs but I'm definitely going to get a few more. I use them as tweezers to hold small lengths of welding wire for Tig work. They're the best thing I've found for it. Little trade secret I'm willing to share ;-) Cheers and thanks!

-

Can anyone tell me what this tool is? I have used it so much that it's starting to come apart. I wish I knew the name of it and how I could by several more of them. My mother's grandfather was the first owner and it was passed down to me. Thanks for the help

-

Does anyone know where I can buy a mini welding table/platten? 16"x10" would be the largest size I need. Anything smaller would be fine as well. Think 1/16 to 1/12 RC Car size. Only one I could find is this, but I can't find out where they sell it. Thanks, Av

-

I'm taking on more welding jobs and wondering if I need a welding certificate. Outside of jobs that clearly call for it the only thing I can find in my state that legally call for it under the ORS revised statues are welding on pressure vessels and boilers. Are there any jobs I would be advised to turn down simply due to intrinsic liability? I've avoided a lot of critical structural welding jobs simply because I haven't purchased expensive business insurance yet. Though I imagine if someone (or something) is injured it's not going to matter if you have a cert or not. All that will matter is whether you have insurance to cover the liability and whether or not your negligence rises to anything above a civil act. Some things I'm concern about welding on are vehicles, trailers, aircraft, handrails, etc. Does anyone here weld on these things where certificates are not needed?

-

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

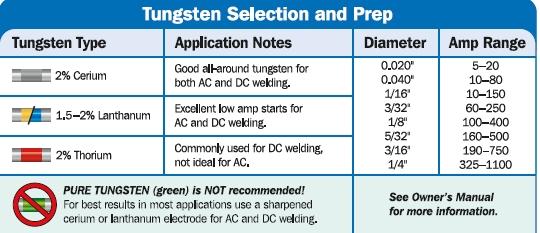

The adage of using green only for Aluminum (as I understand it) used to be true because people were welding with transformer machines several decades ago. However welder technology has changed and the inverter machines prefer Grey tungsten/2%Cerium (formerly orange) for Aluminum. Blue/Lanathanum also really works as does Red 2% thoriated. The reason it's hard to completely answer the question is most of these rods weld DC/AC well and some work better for different metals and at different thicknesses so it's a bit complex. Specifically for thin aluminum everything I've read points to Blue, Grey and Red Tungsten being the best/useful. I have read that the radioactive material in thoriated tungsten is bad but I've not grown any third arms (yet). I doubt anyone wears a respirator when just grinding a small point on the tungsten but I suppose if I was really grinding into those reds for some reason then some caution could be a good thing. Radioactive dust in your lungs or sinuses sounds bad. Experts Weigh In In selecting rare earth tungsten, industry experts recommend 2 percent ceriated, 1.5 percent lanthanated or 1 percent lanthanated. That's because ceriated and lanthanated hold up better for AC applications than 2 percent thoriated, and are radiation free, unlike thoriated. The most common electrode used in DC applications remains thoriated. However, because of concerns about radiation, most experts strongly recommend ceriated and lanthanated electrodes for both AC and DC welding because of their superior performance and the fact that they are radiation free. Tests have demonstrated that the ceriated and lanthanated electrodes are equal to thoriated electrodes in terms of their welding properties and even surpass them in some respects. Both the ceriated and lanthanated electrodes are DC- and AC-weldable and can be used universally for almost every welding task. -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

Just FYI if anyone is welding thin Aluminum I got the following from Arc-Zone. From what I could tell perhaps one of the only people online that carry all this in one place. But it helps to know the decimal of what you're looking for otherwise it becomes impossible to find. Amplify™ 2* Thoriated - Red Tip™ [8662] Tungsten Size: .040 (1.0mm) x 7 (177mm) Item# A-EWTh-2- $8.85 USD 1 $8.85 USD Amplify™ 2* Thoriated - Red Tip™ [8662] Tungsten Size: .020 (0.5mm) x 7 (177mm) Item# A-EWTh-2- $8.25 USD 1 $8.25 USD Amplify™ 2* Thoriated - Red Tip™ [8662] Tungsten Size: 1/16 (1.6mm) x 7 (177mm) Item# A-EWTh-2- $14.25 USD 1 $14.25 USD ER4043 - Aluminum / Silicon TIG Welding Rod - 1lb. Pack [8715] TIG Rod Diameter: a: .035 (0.89mm) Item# ER4043 $45.00 USD 1 $45.00 USD ER4043 - Aluminum / Silicon TIG Welding Rod - 1lb. Pack [8715] TIG Rod Diameter: a: .045 (1.14mm) Item# ER4043 $18.00 USD 1 $18.00 USD -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

This is kind of interesting... Q: Which filler wire is best for welding 6061-T6 aluminum, 5356 or 4043? A: Both are acceptable for welding 6061-T6, but each has advantages and disadvantages depending on the application. An aluminum alloy containing 5 percent magnesium, 5356 generally is stronger and more ductile than 4043. But 4043, which contains 5 percent silicon, typically flows better, is more crack-resistant, easier to weld with, less prone to weld smut, and yields a more aesthetic weld. You're probably wondering this: If 5356 is stronger, shouldn't I always use it? The answer is no. While 5356 is stronger than 4043, they're both stronger than the weakest area of the heat-affected zone (HAZ) in 6061-T6 butt welds. These butt welds fail in the HAZ—not in the weld metal—and the strength doesn't change, regardless of the filler metal. This isn't the same with lap or fillet welds. These welds almost always are stressed in shear loading in real-world designs, not in tensile loading like butt welds. Lap and fillet welds usually fail in the weld metal, and 5356 has a shear strength almost 50 percent higher than 4043. Again, 4043 is less crack-sensitive than 5356 and shows less tendency for crater cracking. If your component will be heat-treated after welding, use 4043; 5356 can be made susceptible to stress corrosion cracking after heat treatment. Similarly, if the component will operate at temperatures above 150 degrees F, use 4043 to avoid stress corrosion cracking. But if the component will be anodized after welding, use 5356. The high silicon content of 4043 will cause the weld to turn black during anodizing, making the location of each weld obvious and unattractive; 5356 will anodize to a silver color. -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

Hi John, I read two long articles on which tungsten to use for Aluminum welding. Apparently it's a far more complicated issue then I ever thought possible. Many rods will weld AC Alum but some are better in certain applications and certain thicknesses of metal. Well after my head was swimming with all the information, my main take-away was that 2% thoriated is still the most practical for welding aluminum, especially thin sheet. Though there may be times where the GREEN pure tungsten and the RED 2% Thoriated should be compared for highly specific applications. I was also reading good things about Ceriated tungsten. I'm going to try out those specific settings on my Dynasty and see how this works. I've been Tig welding Mild for half a lifetime but I'm slowly treading into the territory of aluminum with so far fairly good results. Of course I'm testing all these procedures before I weld on final parts (robotic structure). What I'm welding is .065 Alum to .120 Alum thick material. It's 5/16 by 1-5/8 (custom size) Aluminum angle .065 thick to .120 plate. I haven't noticed any cracking using 4043 but I don't think that is the best rod for 6061T6. My Electrode is 2% Thoriated .065. I am going to get .040 and .020 electrodes to play with them but I think .065 is good for this procedure I just think my filler rod is too big. From what I've heard you generally want an oversize electrode/tungsten when welding aluminum then you would with mild steel. Thank you for all this information on surface preparation, I'm going to print that out. That is going to be super helpful. Cheers, Av -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

THANK YOU!! Iron Wolf.. that was exactly the information I needed. Once I had the exact decimal I could look them up properly and find them through Arc-Zone and Aircraft Spruce. Yes they do make .035 and .045 now I just have to find them in 5056. I was trying to avoid mig wire just because it's rather annoying to have to straighten it out and when it's curved like that it can hinder the uniformity of your weld. I'm doing very micro welds on a robots guts. -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

Yes I saw mig wire on another site somewhere but I wondered if the properties would be similar to TIG rod? -

Smaller than 1/16 Aluminum TIG filler rod?

Avadon replied to Avadon's topic in Welding/Fab General Discussion

Also what is the best Tungsten Electrode for welding thin aluminum? I'm using a Miller Dynasty 200DX -

Do they make any aluminum Tig filler rod that is smaller than 1/16? I'm hoping there is 3/64 (.0468) or 1/32 (.0312) but I can't find it anywhere. I'm trying to weld 6061 Aluminum.

-

OMG how embaressing.. I don't know why I said W-2 lol. Yes it is S-7!!! Seriously sorry about that mix up. Wow I don't know how I messed that up. But yes thank you wpearson it is S-7!! That's what happens when a decade goes by! I never labeled the rods but I still have them. So here is the pics of the first anvil I made. And yes thanks for the correction it was S-7 Air hardening Rod. When I was looking at the specs for W-2 the other night it mentioned quenching and I never quenched it which should have been my first clue. Thanks for catching my error. The S-7 is what we are talking about. This alloy displays excellent toughness and shock resistance with moderate wear characteristics. It performs exceptionally well for trimming, cutting, shearing, slitting and punching operations. Typical Chemistry: C Mn Si Cr Mo V As Welded Hardness: 50-60 HRC .50 .50 .60 3.3 1.5 .25 Available Forms: Stick Electrode, Solid MIG Wire, TIG Rods and Metal Cored Wire So perhaps it's closer and mayble slightly harder HRC then most high end anvils. The next anvil I want to make is a massive version of one of these. Anyone ever made one like this? (See Below)