-

Posts

378 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Montreal, PQ, Canada

-

Interests

Wine, Bbq

Recent Profile Visitors

-

-

@KenH here the dies setup. For the upper part, I replaced the quickpins with 1/2 bolts on which I welded butterfly wings. More economical and just as fast. (Not on the video). IMG_9348.MOV 1-1/4 bolt... it will made a nice ashtray IMG_8334.MOV

-

LOL,... no problem I can demonstrate something. But I assure you that making cigar ashtrays with a single heat is possible.

-

It's been a long time since I've been here, I have some reading to catch up on. I present to you a video of my forging press, it is the 5th of this model that I have made Capacity 16T, motor 5hp, pump 11g/m. All parts are laser cut. My die collection also grows each time. presseV5.MOV

-

What did you do in the shop today?

blacksmith-450 replied to Mark Ling's topic in Blacksmithing, General Discussion

M.J.Lampert I cut circles with a hole saw, after, punch and hammer.... -

What did you do in the shop today?

blacksmith-450 replied to Mark Ling's topic in Blacksmithing, General Discussion

-

-

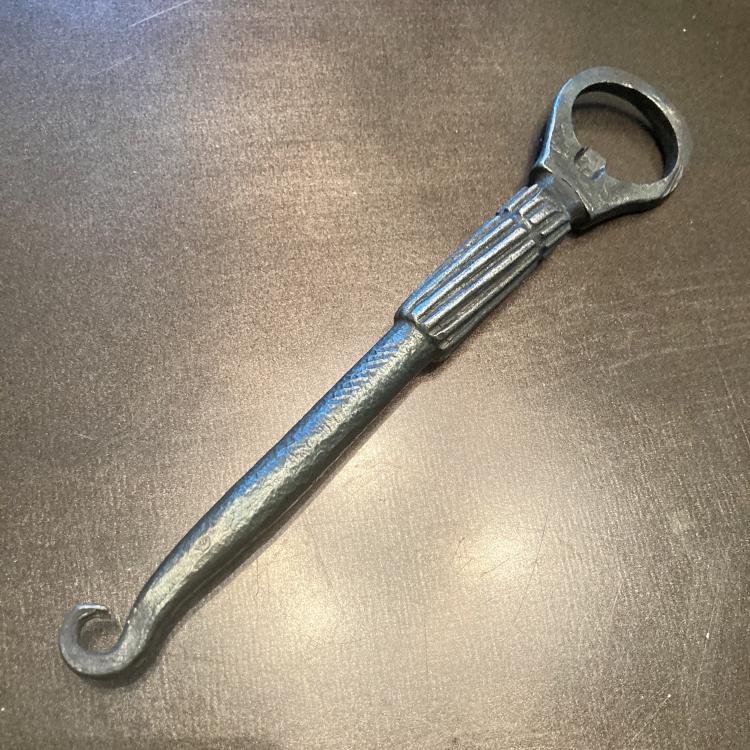

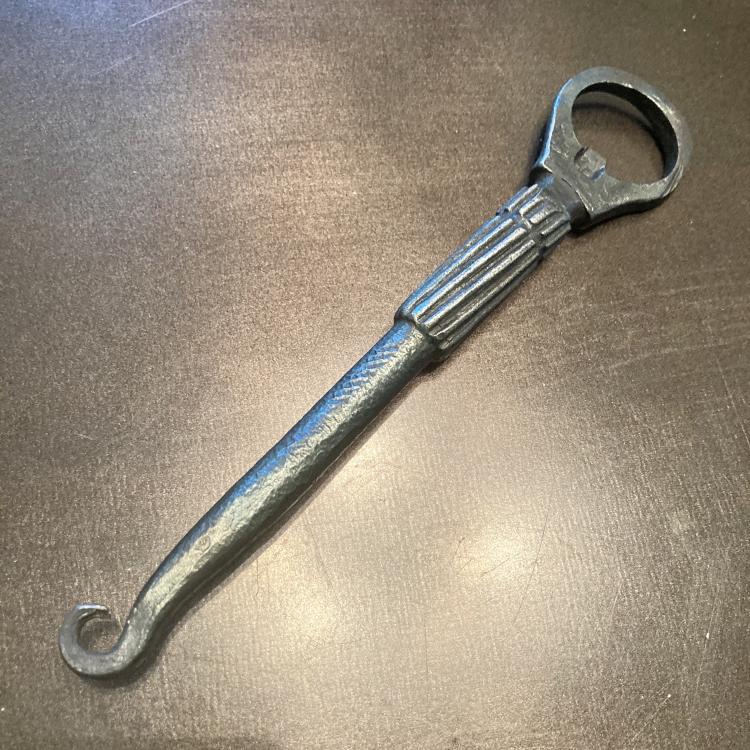

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

Great idea ! -

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

for the thumb, I make a cut at 40 degree, stretch and bend.... -

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

blacksmith-450 replied to Arbalist's topic in Blacksmithing, General Discussion

-

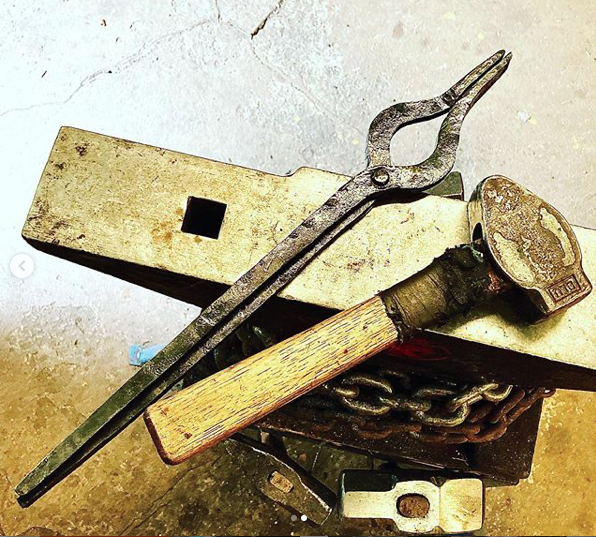

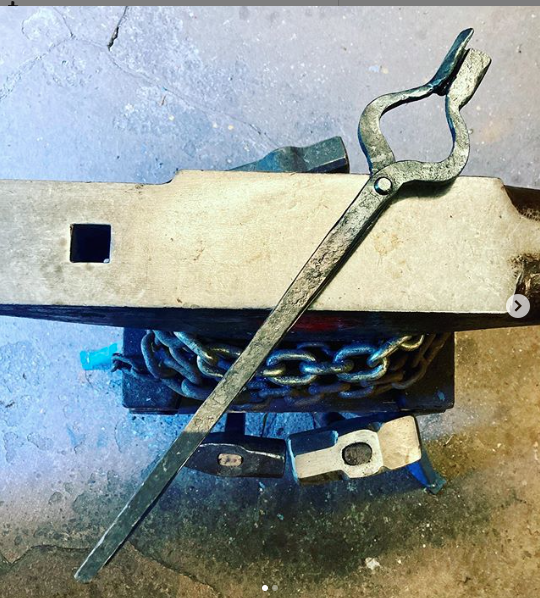

What did you do in the shop today?

blacksmith-450 replied to Mark Ling's topic in Blacksmithing, General Discussion

Ce n'est pas le concours de celui qui a la plus grosse, mais tu as trop étiré AMHA. J'ai fait 2 pinces dans le même après-midi. J'ai laissé les poignées carrées. Merci pour le bottle opener, c'est mon meilleur à date ! It's not the contest for whoever has the fattest, but you stretched AMHA too much. I made 2 pliers in the same afternoon. I left the handles square. Thanks for the bottle opener, it's my best ever! -

What did you do in the shop today?

blacksmith-450 replied to Mark Ling's topic in Blacksmithing, General Discussion

Bottle opener form a random shaft Tu as dû avoir du fun à étirer les poignées.... You must have had fun stretching the handles ....