All Activity

- Today

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

-

To those who keep posting that brass knuckles are illegal in the US... no... they're not. They're illegal in the portions of the US the remainder of America would like to purge itself of, but in many states in the US, brass knuckles are completely legal. In others, they're considered a lethal weapon, but where you have a permit to carry a weapon, you're allowed to carry brass knuckles. Now... in inbred leftist states like CA, WA, CT, etc... they're expressly prohibited. Now let that sink in. In CA, at least in those counties that still respect the constitution, you can get a valid carry permit for a gun. But it doesn't allow you to carry brass knuckles. Because... you know... logic.

-

whitewill1412 started following I scored a whatsit

-

I just got a pair of tongs and a leg vise mount from a guy on Facebook. Now I don't have to make a mount for my second vise. I don't know what these tongs are for though. They are long. 37 1/2" long. Very strange jaws. What are they?

-

What did you do in the shop today?

George N. M. replied to Mark Ling's topic in Blacksmithing, General Discussion

Another critter that will mess with you through speed is the pronghorn antelope. They can hit 60mph full out. They also use speed as showing dominance. If they can show you their white butt they WIN. Years ago I was out in central WY in my old 1948 Buick going down a 2 track trail and a couple young bucks decided to race me. I got up to about 40-45 mph on the 2 track which was way faster than prudent and they were just loping along. They then kicked it up a gear, cut in front of me, and showed me their white behinds and took off across the prairie. They are really cool animals and one of the things I like about where we live is that they wander through our front yard. GNM -

Yeah I really like black bear forges videos. I like Alec Steele too and I've seen some other good ones that I don't know there names. There is one blacksmithing basics video that was made for DVD on YouTube that was filmed one county over from me in Hookstown PA. That's a real good video. I've watched it a few times and I'll watch it some more too. That's not really that close to me. PA is a big state. But thanks for the suggestion Thank you all for the welcome. I'll probably be on here a lot. Maybe not posting a ton, but reading and learning for sure

-

Just another option. I have a 15KW US Solid induction forge. The forge and a TIG cooler ran just over $1,600 when I purchased it a year ago in February. A good unit, never had any problems. Came well packed and in a very reasonable time frame and tech support through a US company. Here is the description of the IF and TIG cooler. U.S. Solid 15 KW High Frequency Induction Heater 30-80 KHz U.S. Solid Tig Water Cooler 25L TIG MIG Welder Torch Water Cooling Machine, 370W, 0.33MPA That said, the Coal Iron offering was not available when I purchased my unit. It was introduced a few months after I bought this unit. The Coal Iron unit is more expensive but it comes with: 100% tech support from a US company pre-assembled and tested (just add water and plug it in) although I have not had any problems with my cooler (some owners have reported water-fail alarms), I do like the Coal Iron cooler. IMHO the whole unit comes as a neatly assembled package with Coal Iron support standing by to help should any problems arise. As you might be able to tell, I am a fan of Coal Iron. I have one of their double-sided 25 ton presses. They are always there to help. It's your choice. Both good options. Your choice. Good luck... Dan

-

The top one looks kind of like a Dingle but not one you'd carry in the field to sharpen a sythe. Could've been used to sharpen, repair or make them in the farm shop. Frosty The Lucky.

-

I think we're getting close to voiding the thread of subject material. Please take note, Frosty is NOT taking up the great big stinking straight line offered in the previous post. De Nada, you're welcome. Frosty The Lucky.

-

Star power hammer restoration WIP

Frosty replied to White Fox Forge's topic in Power Hammers, Treadle Hammers, Olivers

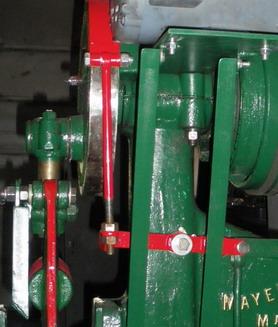

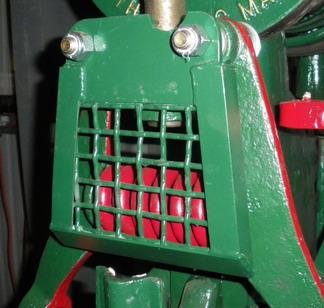

I'd leave the springs together and soak the stack. I got involved in acetone ATF mix's ability to bust rusted parts and lost track of you want to treat the whole hammer. It busts rust so parts can move against each other I suppose it'd make it easier to wire brush off but even after the acetone evaporated ATF is pretty flammable and power brushes throw sparks. There are lots of "rust restorers" available on the market. a search with those terms gets pages of hits. The old school ingredient is phosphoric acid and leaves a flat black iron phosphate patina. Navan Jelly is an old and effective product. I've brushed it on to good effect but it works much better soaking. Another old name that comes to mind is "Ospho" back then it was what we primed rusty metal with before painting, I worked at a company that made tanks, some buried, some not and many needed special anti rust protection. To paint that old lady I'd wire brush it (done) and spray it with a primer that converts rust to pure iron then give it a couple coats of acid etching epoxy primer then appliance paint. You can buy a cheap airless sprayer for not much and the 2 part epoxy paints are incredibly tough. My old Little Giant lives a sheltered life so it has multiple coats of Krylon Epoxy (Uh, maybe it was Rustoleum epoxy I don't recall) and it laughs at the oil and . . . stuff that leaks and sprays off the hammer's works. In my shop colors of course, forest green and gold, I THOUGHT it was original in the day.<sigh> The first pic is how I mounted the motor and rigged the clutch linkage to the brake I made it default to stop when you're off the treadle. The second pic is the scatter shield I made over the brand new spring. All the dangerous moving parts are red, I put 1" Grizzly screen in front of the spring rather than sheet steel so I could see the spring. They tend to stretch before cracking before breaking. You can SEE the paint peal over cracks. Also, the screen tends to catch flying stuff because it flexes rather than bounce it off. That's my old girl, I call her Bobby after my Mother. Different story that. Frosty The Lucky. -

Ayup, there's no better reason to not get mad at people pointing out the obvious, I've been missing the obvious for 70 years now, it only took me 50 to learn that lesson. Frosty The Lucky.

-

What did you do in the shop today?

Frosty replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks pretty good Gewoon, you're turning out some nice work. Oh yeah, Roadrunners can fly just not well nor far but they can easily land 30' off the ground on a limb or bluff. They make turns and stop almost instantly just like the cartoon buy using their wings. They like to toy with animals that'll chase them, slow down till the dog is almost within snapping range then the wings snap open and they bang a 90 or go up over and behind. The faster the dog the better the game. I used to run with them on Banjo my horse but never got close to catching up. You don't want to on a horse the runners like to startle the pursuer and that is a B A D thing at a full gallop! Here you go, Frosty The Lucky. https://www.audubon.org/field-guide/bird/greater-roadrunner -

Some of the finalists on FIF had induction units in their home shops. Well said as usual Latticino. Sometimes I'm afraid I have a reputation as a wet blanket with the newcomers to the craft. But as said already it's normal for someone breaking into a craft, any craft to want to buy the best tools and equipment available. I highly vouch for the advice given above, the BEST way to learn the craft is from an experienced mentor and blacksmiths seem to be more than happy to help new folk. Unfortunately the best tools in the world are nothing more than highly refined dirt without the mind and hands of a human to make them do their stuff. Without knowing how to use a tool you could well be endangering yourself and those around you. You can do top notch blacksmithing and bladesmithing with nothing more than you can carry in a bindle or what's available where you build a fire. I used to have a field job and rather than drink a half rack of beer in my off time I played with scrounged materials in the fire. My only tools were a 32oz. drill hammer, a couple chisels, file, brush and hack saw. Typically I cut scrounged stock long enough I didn't need tongs but you can split a green stick for short lived tongs. The minimum tool list for a blacksmith is surprisingly short. Anvil, hammer, something to cut with (chisels are give away cheap at yard/garage sales) and something to hold hot stock. The rest is icing, NOT necessary to the craft. More importantly is PPE, eye protection is a MUST and no, your reading glasses aren't good enough. I have poly carb protective glasses with side shields as my daily spectacles and use a face shield if my experience says the process MIGHT put debris in the air. I have over the glasses BUG goggles for really dirty things, sawdust is a dangerous eye irritant and should Always be avoided. NO synthetics, on contact with anything 300f and above it melts and deep fries your hide, trying to scrape if off generally adds your hands to the menu! Even Nomex isn't good in a smithy it is for short term flame contact and does NOT stand up well to hot material contact except briefly. (read seconds) High top leather shoes preferably without laces, hot pinch offs LOVE to find nooks and crannies to fall into, shoe laces and pants cuffs are favorites. Hmmmm? Same for your work area, NO flammables that aren't going into the forge! Places like under shelves, behind things, etc. collect dust, leaves and litter so that is exactly where pinch offs are headed! Keep your work triangle/circle clear of trip hazards, stumbling when you have a piece of 2,000f bar in your hand or tongs can be disastrous, on the upside 4th degree burns don't hurt but they can make it tough putting out a fire before the shop, house or yard is involved. If you're going to wrk in the yard, rake up leaves and litter, then give it a good wetting down with a hose for a minimum 30' radius. 30' is minimum, when you cut something with a chisel the bit you cut off (Pinch off) can fly that far easily. With experience you'll learn to chisel cut stock without letting any fly but until you do, don't take chances, please. Yes? I'm starting to ramble aimlessly . . . AGAIN this morning! We hang out here on the forum largely to answer questions, solve problems and help folk get started. Give us a shout out when something comes up. Frosty The Lucky.

-

Excellent but not too surprising with the bee die off of the last few years. When nature rebounds it's usually fast and hard, large parts of the world need to be recolonized by buzzers. Do they drink from water where you do your casting or the green sand itself? I'd be seriously tempted to think they need the minerals in your green sand and put out a pan near the water you put out for them. Maybe even mix a little in their water. Hmmm? I sure wish I'd gotten your kind of hives instead of the shingles. Well, maybe not, Deb's allergic. Frosty The Lucky.

-

I'm an active member of ASTM and user of their specificaitons. Not only do they have specifications by application, such as the music wire , bearings and rail road applications but within a given standard their are often several, sometimes many, different grades. For example, Specification A350 has several different grades with substantially different compositions. We work with A350 LF2 and LF6. Those names have no connection to the composition, they are just generic labels so you have to look up the spec to see what the compositions are for each of those materials.

-

I honestly don't remember seeing induction forges on FIF, let alone large ones. I know they have sizable propane forges as well as electric heat treat ovens, but I don't recall them using induction. I well know the lure of purchasing new equipment for a new hobby, but you might be getting a little ahead of yourself. I recommend you hookup with some of the Ohio smiths and see if there is a group near you, or a class that you can take. You can learn a whole lot more from in person direction than from watching Youtube or FIF. If I recall correctly, there is a pretty large contingent of smiths in Ohio, and even though it is a large state I suspect there will be a branch of ABANA nearby (or near Pittsburgh as you appear to be close to there). Now that I think of it, the annual ABANA conference is just outside Pittsburgh in June. If you want to see some fantastic work, tailgating and comradery you might want to look into that as well.

-

latoking joined the community

-

What did you do in the shop today?

gewoon ik replied to Mark Ling's topic in Blacksmithing, General Discussion

After long absence to my shop, I finally finished 2 tongs I started. Both for 6mm flat. A normal one and one for hoops (have to make one). Was fun to make. pictures only of the one for hoops. The other is the same but shorter and straiter beaks. And on the picture i see that the reigns are wonky. -

Agreed, interesting how when you see something and think: Why didn’t I think of that.

-

What did you do Outside the shop today?

Nobody Special replied to TWISTEDWILLOW's topic in Everything Else

Split a beehive, one that I just split about three weeks ago. I treated for varroa mites too late last year and paid the price by being down to one hive this spring. Had to put a second deep on it by March, and mind you it was still rainy and down in the 30s. Mid-April it was full to bursting and making queen cells. I split it in thirds, and at around three weeks, just had to do it again. I won't get huge amounts of honey but went back to five hives from one. I may just deliberately keep that hive small one more time so she keeps making queens. "A swarm in May is worth a load of hay, a swarm in June is worth a silver spoon. A swarm in July, ain't worth a fly". No pics of the split, because they caught me off guard, but to keep it metal related, here's one at the foundry. They frequently come hang out when I temper my greensand. I always put fresh water out for them, but they seem to like the water over there better. -

Welcome aboard from 7500' in SE Wyoming. Glad to have you. I second what Swedefiddle said about getting involved in a blacksmithing group. You will become a better Smith much faster. Some of us learned on our own and it is not the optimum way to do it. I started on my own in 1978 and all I had were books from the library, some really nasty coal, and my own mistakes to teach me. I never met another smith until I had been doing it for 12-15 years. Today there are good books and good videos available. There are some BAD videos on You Tube but some very good ones. I like Black Bear Forge, JPL Services (or own Jennifer), Torbjorn Ahman (from Sweden), and Christ Centered Ironworks. Some folk like Alec Steele but I find his style of presentation to be kind of annoying. There are others that are good but it doesn't take to long to distinguish the good from the bad. And don't forget honest to god print books. I'm old fashioned but I find hard copy books to be a very good way to learn. When combined with good videos you will learn much faster and better than I did. "By hammer and hand all arts do stand."

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Wait, the road runner would land? I honestly did not think they could fly. -

I brought these home from a barn sale a week ago. The barn had been in the same family since the 1700s and the road it was on was indeed the same name as the family name. There was a rivet forge that I didn't need and a post vise but the seller said he was taking it back to Oregon but I don't think in his carry on baggage. I hoped for for more neat old stuff but this was it in that category. Not sure what the hardy tool would have been used for with those narrow V's. I'm guessing the chisel thing is for laying out curved lines in hot steel, like veins in a leaf. The spike round top tool is kind of a mystery too. The dome part has some fractured off bits so it must be hard steel and the spike suggests it was driven into a stump. Are the fractured parts the result of striking it? These and a few larger spikes, cold chisels and 5 pick axe heads were $10

-

Good Morning Will, Welcome from the Left Coast. It seems to me, you live in the middle of a VERY ACTIVE Blacksmith Association P.A.B.A., https://paba-site.org/ Check out your local Blacksmith's first. Neil

-

That mixture is usually used as a penetrating oil like Kroil and it works wonders for freeing up rusted nuts & bolts. I've never tried it as a rust remover from surfaces. Might try it on a small piece before covering the whole frame. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus