-

Posts

77 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Mora, MN

-

Interests

Knife making, blacksmithing, leatherworking, woodworking, playing piano and electric guitar, hunting and fishing.

Recent Profile Visitors

-

White Fox Forge changed their profile photo

-

I welded up a handle for the press and will eventually use a pedal. I made a prototype pedal but the action caused the press to stall out. I think that I may have to redesign the pedal. The press can crush a peice of 1 ½ inch steel down to about ⅜ flat in one heat. I like the freedom to work with bigger steel bow that i have a metal musher. I need to fine tune everything. I still need to make a top die retainer. I'm out of ideas... there isn't enough room to make a gravity swiveled retainer. Cheers! Wff 20240407_194419.mp4

-

I got it running. It still needs a ton of work but it is fuctional. I'm in the process of making a pedal for it. VID_49161119_181016_022.mp4

-

-

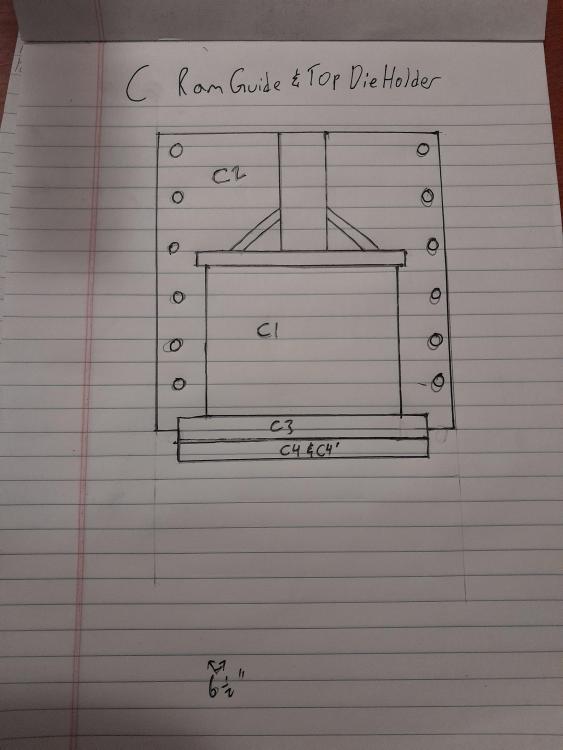

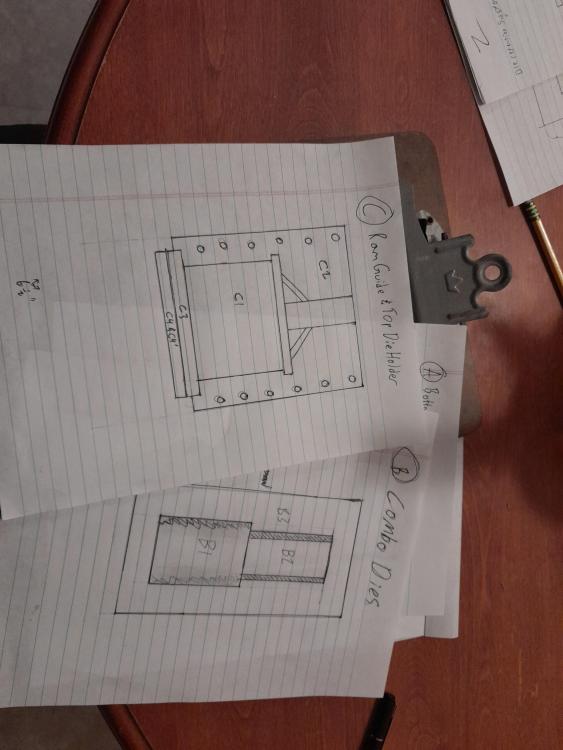

This migh help clear up confusion. I tacked up the top die holder and ram guide. I will do the same for the bottom guide. My little 110v Lincoln flux core isn't nearly big enough to glue this son of a biscuit together so my neighbor is going to let me use his larger welder. I have a combo die setup and I have enough steel for one more kind of die. Not sure what I'm going to do yet. I think I'm going to stick to the steel guides for now I can always switch them out later if need be. Hope this helps clear up the prints a little lol. I should also add that the die holder I have in the picture will be the bottom die. I just used it for reference. The too die holder is made of ½ inch plate steel instead of the meager ¼ inch.

-

Thanks Scott. Frosty: you are right. The sketches do net elaborate enough. I should've put more of a description on the parts. The sketch is of the guide, die guide and dies. The combo dies are in the sketch and in the picture. In plan C the die guide/holder is sideways so it is difficult to picture. I am using angle iron to retain the dies. To remove them I will slide the dies out horizontally. I've seen guys bolt them on but I don't have a big enough drill press or taps to do so. I'm just going to weld it all together. I did see (I believe it was on IFI) a press on which the maker used a type of plastic as a spacer in between the ram guide. I've also seen some presses use aluminum bronze. Is there any pros or cons to using steel vs bronze vs plastic? I would think plastic would bend and shear under even 22 tons.

-

White Fox Forge started following What did you do in the shop today? and Log splitter forge press build WIP

-

Hi all, I'm working on turning a 22 ton forest king log splitter into a forging press. I bought this one last fall but never got around to converting it. I've wanted a press since I started making knives. I considered purchasing one however it is a little out of my price range. I have the steel, tools and (hopefully) the enginuety to make my own. I bought three log splitters before I found one that I liked. The reason it took me that many tries is because the previous splitter had too much wobble iln the guides. This one is adjustable (I can make my own tighter guide if I need to) because it unbolts from the I beam. I'm planning on cutting the wedge off, welding a big steel cylinder to it to add support and then adding the top die. The bottom die will be made separately and then welded to the machine. I don't have a big enough welder so I'm going to tack the prices up and bring it over to a friend's shop to use an industrial welder. I have drawn up dozens of prints for this build and these seem to fit the best. I have the prints and parts labled to help avoid confusing myself. My only dilemma is with die retention. I've seen guys use a peice of steel that acts as a flap to hold the die in. I've also seen the same flaps bend over the years of use. I'll have to do some more research before I pull the trigger on a certain design. I have the bottom die holder almost completely cut out and the top die will be next. These are my goals for this press. 1. Be able to draw out billets of damascus, break down tool steel round stock and make hammers. 2. Have a smallish foot print. 3. Have universal dies that are easy to make. I will leave the gas engine for the time being because I don't have enough electricity to the shop to run a 220 motor. Cheers! WFF

-

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Yessir! Four parts. The ring, tube, collar and bit. -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

I worked on a key for a immigrant chest and lock I am making. The key is still really rough and needs some clean up on the intricate parts. -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

I cut out a newish design of knife. The steel is the usual, 8670 and the handle scales will be waterbuck horn. I boiled the horn in hydraulic oil for an hour and it got soft enough to clamp straight. I'm probably going to try a hamon on the blade. -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice twist gewoon. Looks really good. Nobody, I took a pic of the cable damascus. Forged it into a puuko. I didn't harden it so I didn't get a good etch. You can kinda see the pattern though -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Nobody! I'll have to take some when im in the shop next. I'm having trouble getting the watering right but I also forgot to quench the cable damasucs lol -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

I finished up the handle on my tomahawk. Surprisingly the handle was harder to make than the head. It throws super nicely too! -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

My new design for railroad spike tomahawks. I welded two together for more metal. I like this better than my first attempts. I also welded up some cable damascus which turned out wonderfully. Don't have any finished pics of that tho. I love working with cable damascus. -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Alright. I'll do that next time I'm at the shop. I did make the medium and it makes the file skate across the tomahawk like with a regular knife. Unfortionately the hawk turned out pretty terribly. The head is crooked, the handles cracked and the bevel is too sharp. That one goes to the scrap bin lol. Hopefully I'll have better luck on my next couple attempts. It is my first rr spike hawk after all. I'm hoping to get a bit more of a beard on my next couple. Also my drift is deformed and not the right shape. I'll probably make a new one soon. Drifts are always pretty difficult for me to make lol. Is there a difference in using a round drift and a tear drop drift? I could probably use my hammer drift. They are only going to be throwing hawks anyway. Cheers! WFF -

What did you do in the shop today?

White Fox Forge replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok. I'll try that. Lucky for me I have all the stuff to make it right under my kitchen sink lol. I'm planning on trying my hand at a few more hawks or spikes tonight if I get time. I'll post pics and results if I do. WFF