-

Posts

2,136 -

Joined

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chris C

-

Thanks for the info. Only I don't have the slightest idea what you are talking about. That's why I'm probably going to have to pay my electrician to hook it up. I've got 3 wires: White, Black and Red, along with a copper ground. I don't even know which is the "common" and which are the Hots. I'm okay with 110V. (well, I haven't electrocuted myself yet!) But 220V might as well be Greek to me. On the back of my wall outlet there are 3 connection points. One of them is marked Green, the other two unmarked as to color. On the breaker, there are only two points of connection. (3 wires and a ground and only two connections) With #6 wire, there's no way I'm going to be able to hook two wires into one of those connection points.

-

I got my 6-3 Romex run from the breaker box, up to the attic, stapled to the rafter all the way over to the other side of my forging room for my welder. About 65 1/2 feet of Romex. Now to figure out how to hook 6-3 with a ground to an outlet that only has three connectors! Oh, and the 50 amp breaker only has two! So I'm fumbuzzled. Looks as if I'm going to have to pay my electrician $200 to hook it up!

-

Cool, thanks. I like the deeper sound. It's so much easier on the ears in comparison to the twangy higher pitched triangles I've heard in my life time.

-

Well, in my personal case, it has nothing to do with tough..................more to do with just plain lazy. Too much trouble to go get a respirator, full-faced mask, safety glasses, hearing protection or gloves from their respective hiding places in my shop when "I'm just making a quick cut" on something. I know full well I should wear a respirator when sanding handles of knives on my belt sander and yet, more often than not, I realize half-way through the job I don't have one on......................then I think "oh well, I'll be finished in a minute". My own laziness. I know full well it's just a bad habit that has to be replaced with a good one.

-

I've only got a minuscule 4" r-angle grinder. But I give it great respect. I was trying to cut something a year or so ago and that danged guard was getting in the way. Loosened it and moved it a bit and tightened it back up. Made the next portion of the cut a whole lot easier! Then, once again, the guard was getting in the way.........................repeated the process. And, later on, the same process. Then the thought to completely remove it momentarily flashed through my mind..................as did thoughts of shattered blade pieces stuck in my face and fingers. Left the guard on the grinder and only tightened it to the point it would stay where I left it, but could move it a little bit if I needed to. It's worked well for me in the configuration ever since. Oh, and since that day of realization as to what might happen if the blade shattered, I've started using a full-faced shield. Don't know why I never did before that, but at least "as we git older-we be smarter"!

-

Holy Cow! I can't believe they weren't turned in to OSHA for doing that. (And I say that, even knowing how much I hate OSHA!) The owner of the company should be serving time in prison for that "time bomb"!

-

Amen to that. Most people in this country are "standing on the shoulders" of folks from the Greatest Generation and just don't know it.

-

I wanna "hear" it more than see it! That's got to be more of a gong than a mere dinner bell.

-

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

No, these little wood carving knives are all stock removal. I've only done one forged knife so far. Not ready to tackle all my little carving knives. Many are only 3/32" thick at the spine. Don't want to have to try to pound those out. They'd cool too quickly on the anvil, I'd think. -

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

Got five wood carving knives epoxied up and ready for handle shaping. Coated my (yup, still working on it) forge with Metricote today. Also cut the "tables" for the front and back of the forge opening so I can set my two fire brick "doors" on each end. Cut and drilled the angle iron brackets I need to weld onto the forge to mount the "tables"..............but can't do that until I get my 220v line run from the box to the forging room..........65' of 6-3 cable to staple up to the rafters. Next thing to accomplish is to cast my ribbon burner. -

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Prayers for you and your family Chellie. God Bless all of you. These can be really tough times. I'll keep all of you in my prayers and thoughts.

-

Okiepan, It would help if you'd fill out your profile so we know where you are located. "Somewhere" in Oklahoma, I'm assuming. The reason for that is there may well be someone smithing in your locale who could be a real one-on-one assistance.

-

That's the biggest darned go-cart engine I've ever seen!

-

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

That's really nice, KYCATS. -

"Where there's a will, there's a way!"

-

I can buy them on-line for about $25-ish as you say, but then you've shipping to be subjected to! UGH!

-

Dang, I've been looking for one of those cans for quenching.

-

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

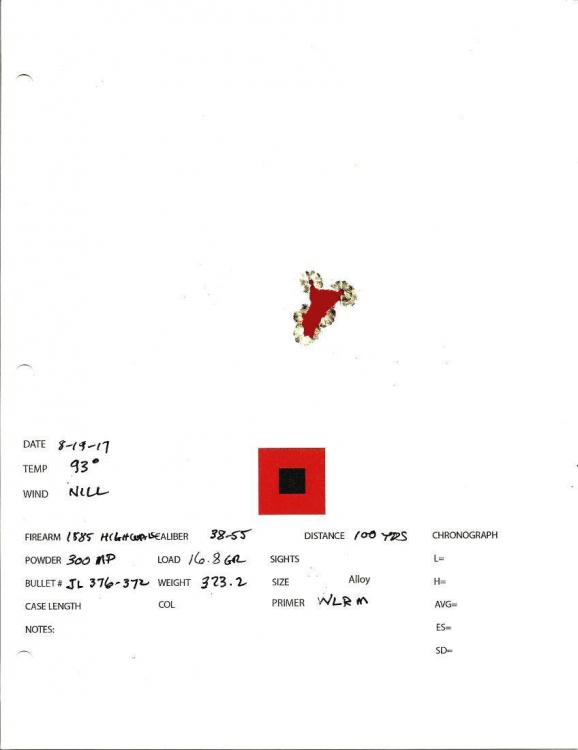

Okay, I've stayed out of this so far, but I just couldn't contain myself. This is my favorite target rifle. C. Sharps 1885 Highwall. 20X Lyman STS Scope. This pic is the first day I got to shoot it and was zero-iong the scope in the lead-sled. This is what it does off sand bags at 100 yds. This is a 10-shot group. The red "sighting square" is 1"x1". After I started breech seating bullets, it dropped to sub MOA at 100yds for 10 shots. (nope, by that time I wasn't taking pics.) Love this rifle. -

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

I've done a lot of rust bluing................and I typically soak the items in oil...........but not stinky used oil. Any oil will darken the surface. I love the look. -

Found a 125' coil of 6-3 on Craig's List today for $160. My electrician told me where/how to install it and he'd come and hook up the connections. My Run is 63 1/2 feet, so I'll have 61 1/2' of 6-3 left over to put on Craig's List to recoup some of my money. Oh, and Frosty, one rule I made when I started this steel bangin' hobby was that "Any money I make goes to buying materials and equipment toward that end!" The money spent today came out of the stash I was saving for my 2x72 grinder. When I sell the knife, that money goes into the stash. No debate!

-

What did you do in the shop today?

Chris C replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice pieces. I'm sure she was tickled. -

Beam Hammer- Has anyone built one!

Chris C replied to Greebe's topic in Power Hammers, Treadle Hammers, Olivers

https://www.youtube.com/channel/UC8WRbArfgi8kSaDek7kh_1Q She's an active member here on the forum. Go through her videos..............you'll learn a lot. -

Beam Hammer- Has anyone built one!

Chris C replied to Greebe's topic in Power Hammers, Treadle Hammers, Olivers

If you will notice, there is only one position where the hammer and anvil contact squarely. I don't think there is enough adjustability to gain much from using this hammer. So this hammer has it's drawbacks. Though, if you are just dying to have a power hammer, I guess this would be a place to start. You sure don't "need" a power hammer of any sort. Just watch Jennifer in some of her videos. She makes hammer heads and all sort of things that many smiths think they couldn't do without a power hammer. -

She's still watching and proud!