-

Posts

200 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

BCS, TX

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Share something the world doesn't know about your job

CtG replied to rockstar.esq's topic in Everything Else

Steve, that is one of the reasons (many reasons) I could never get into the medical field. Human suffering is very difficult for me. The PTSD I have is directly related- let's just say burns above 2nd degree...... trouble me. Enough said. So, more on topic. I am a "Caterpillar Heavy Equipment Maintenance Technician, Field, T5" aka, a heavy equipment mechanic that works out of a truck. I have, officially, a high school education. I am self-taught. No vocational school. So, what don't people know about what I do? Well, a ton, but let me try to stay surface-level. It isn't just "turning wrenches". You have to understand electronic systems, emissions regulations, system interactions, design ideas, customer relations, basic economics, have good people skills, be teachable, be adaptable.... I have tickled a six-figure income multiple years. So, you can make a decent living doing what I do (if you actually care about doing it right) Most of the truly good techs I've known aren't the stereotypical "grunt" type. They are generally very well-educated, just not with an expensive piece of paper with an institution's name on it. And, we keep things moving. Without us, backup generators might not be reliable. Construction companies would experience much greater delays. Roads would take longer to build. Deliveries couldn't happen (heavy diesels power the rails, power ships, and on the much smaller scale, trucks.... even though we don't just do diesel!) -

What did you do in the shop today?

CtG replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice foot flatter! Isolation sucks behind... only free time I've gotten, it's been windy and/or rainy. Would be nice to be able to hang with another local smith haha -

Brazos is... messy. 151/13 It's been low 60's since Monday. Was 90's last week. Shall see. Mornings low 40's. Been wildly alternating between "only 8's" and "EVERYTHING IS ON FIRE!! 16 HOUR DAYS!!" Crazy times continue.

-

Oh, come now TP, I need to know the exact shift, crew, and foreman name! I jest... Thank you very much, I'll pass the info along- I know they'll be absolutely thrilled to know a make with near-certainty and a year range as well. Again, thanks!

-

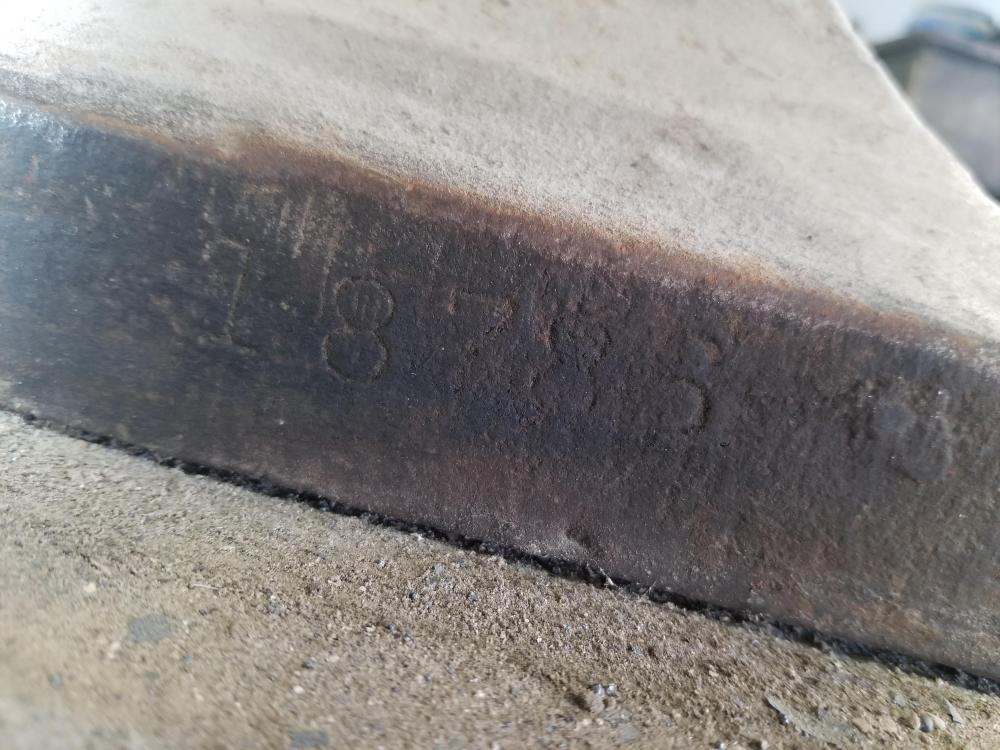

Can anyone narrow it down a tad more? Thanks all!

-

Hey all, I was at a customer site today, and they have a big ole London pattern. No makers mark, no weight mark, but there is a serial number on the RH under the horn, and the bottom has a pill shaped cavity. Also, visible steam hammer marks under the heel. They've been on the site since roughly the 1870's I was told. I got to see the old blacksmith shop- it's storage now and there is a Hotsy under the old forge chimney, but you can see the old anvil stand. He said the anvil is mostly used to reshape pickeroons nowadays. They make rail ties these days.

-

I'll have to shoot my doctor an email and ask about this. If it can be helpful.....

-

Similarly, I developed a funky cough, minor fever, and gnarly headache back in February after a coworker came back from South Korea. Lasted a week and a half, but at that point I figured it was likely a minor cold. Didn't hinder work and was nothing dayquil couldn't handle. Worked it's way around the shop. May have been it, or may have been a different coronavirus, influenza, etc... hard to say. Was still early enough the doc wasn't that concerned that I had a coworker who came back from 2 weeks in S. K. Didn't test for anything. Who knows now?

-

What did you do in the shop today?

CtG replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm sure less wiggle will be needed with refractory weight added. Indexing hinges, nice! What a pleasant song- we are being graced by the calls of grackles of late -

"No entering the shop, all field techs must wait in the parking lot for parts and tooling" Yup. But hey, here's dinner to distract from the virus! Pardon the mess.

-

Yeah, my folks had a big boy at one point with spurs maybe 2.5" long.. I did not enjoy that bird. The big mean ole' geese we had didn't bother me much, but that nasty beasty... A quick google search makes me want to say he was a Copper Maran? We had quite the mixed bag of chickens, only a handful of roosters ever though. The big ole Brahma we had when I was a kid was a sweet guy. The geese were vicious, but had big ole eggs, often double yolkers. Real rich too. Well, 9th anniversary, no going out for us... I still have a job but work is drying up. Several of the field guys have gone without a full days worth of jobs for several days. We shall see how long it holds out.

-

Fixing anvil edge peening/mushrooming

CtG replied to ChiefLittleBair's topic in Repairing and Modification to Anvils

Keith, it's a beauty! Looks like it should treat you well for years to come! -

What did you do in the shop today?

CtG replied to Mark Ling's topic in Blacksmithing, General Discussion

Fair enough! Loctite LB8017 has been one of my favorite dry moly lubes for higher temp stuff if anyone cares haha... Rated to 2400°F as an anti-seize, 750°F continuous as a dry film lube. 400/1315°C. Anyway... -

What did you do in the shop today?

CtG replied to Mark Ling's topic in Blacksmithing, General Discussion

I think they can be had for something like $5 a hinge. I believe some may just be steel on steel with a bronze thrust washer. A dry molybdenum disulphide spray should be good to 1800*F. Usually you buy them either as naked barrel and pin to weld to, or with a small flag to weld. -

What did you do in the shop today?

CtG replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, I don't know for sure on a forge, but I really like pin and barrel hinges for ease of disassembly. I imagine with proper bushing and lube it'd work well.