-

Posts

1,164 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Goods

-

No, it means every forge is different. When you fire it up the color in the forge will tell you more about your forge than we can by guessing.

-

The hot spots are usually under the burner, but every forge is different. On my two burner gas forge, when it’s cranked up high, there is a small cold spot directly below the burners. It’s a tunnel forge that doesn’t have a lot of height, so the gas isn’t all burnt when it hits the floor and actually cools a two small spots… Keep it fun, David

-

What did you do in the shop today?

Goods replied to Mark Ling's topic in Blacksmithing, General Discussion

I’m good with either metric, fractional inches, or 1/1000”. Everything at work is in metric, but a lot of the machinists I deal with all think in 1/1000”. I’m converting in my head close enough for blacksmith work all the time. keep it fun, David -

Forge welding a handle on defeats the purpose. The handle is to make it easier to move the work piece around. If you have to move it around at forge welding temperature to put the handle on, you should already have a different solution. If if have good fitting tongs for 1-1/2” or 2” diameter cable and you comfortable working with those tongs, stick with that. If not, make good tongs for that size, weld a long handle on, or weld a stubby handle on that will fit in the size tongs you have. Lots of options, but don’t make it harder than it needs to be. (Some times it’s fun doing things the hard way, but I don’t think this is the place for that! You don’t want you to loose control of you billet when it’s at forge welding temp, or ever really!) Keep it fun, David

-

Is this sarcasm, or did I miss something? (I can be slow on the uptake sometimes…)

-

One of the smiths in our group built his anvil years ago. He machined the body from block of 4140 pre hard and the base from mild with about 1/4” chamfers at the joint. He bolted them together from the bottom with 4 3/4” socket head cap screws and welded it up. You would never guess that it was made from two pieces and it is great anvil to work on! (I wouldn’t want to move it, the anvil is around 500lbs and the stand is made very stout.) Keep it fun, David

-

Again, what’s your location? I still have one of these, and it would make a killer base: https://www.iforgeiron.com/topic/70036-it-followed-me-home/?do=findComment&comment=787818 Might take a bit of welding but it would probably quadruple the mass! Keep it fun, David

-

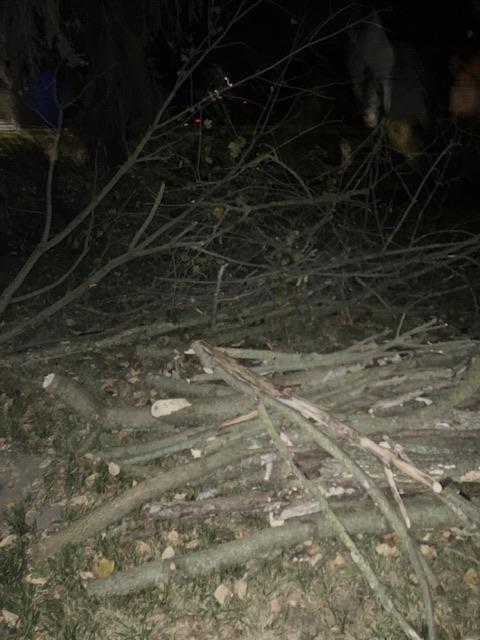

The city (town really) will take the brush away and grind it up into mulch which the gets given away in spring. I gave the first batch of wood to a neighbor whose brother has a cabin on the river. They’ll burn it in camp fires. The second batch of wood is going to my neighbor on the other side. His son-in-law asked for it while I was up in the lift. Not sure what his plans are. That tree was in their yard, while technically on my property. The property line is fairly problematic, but so far we’re good with it. Once my mortgage is paid off, we’ll redraw the line and call it good. I’ll loose some on paper, but nothing in reality. (I didn’t know the property line was seven foot under his garage until I was working on getting a variance for my forge build…) It would be nice to turn it into charcoal, but I think I’m already creating enough smoke in town and keeping the neighbors happy it always a good thing! Once I repair my fireplace, I’ll start collecting firewood for myself, but that could be a while. Keep it fun, David

-

Ok, so I had more work to do today than I expected… I started by trimming the dead limbs out of a Norfolk pine in the backyard. (Lightening damage from a few years ago.) Then, with help from my dad (who was visiting from PA), we cut down another tree piece by piece. I thought that one just had some dead limbs, but upon inspection, it was completely gone. Finally, we moved onto the limb that I was really worried about. It wasn’t real big, but it was dead and above my forge, ready to take out my flue and probably damage the roof. We had to rope that one down in pieces… Tomorrow, I have to return the lift, and finish cleaning up. Unfortunately, my family headed back tonight, so just me and my younger son to get it done tomorrow. With the day off, I was hoping to get some forging in, but I think I’ll be pretty worn out by the time everything is cut, stacked and brush removed. Keep it fun, David

-

Long day today outside the shop. I dropped two smallish trees piece by piece. (They were just too close to the house and the red dogwood in the front yard.) One sugar maple and one mimosa, both never leafed out in the spring. I’ve been trying to get a lift rented for months and finally found one available. I’ve got family in town, so I had some help cleaning up, which was great. We’re going to do some sightseeing tomorrow, so Sunday I probably be back at it. I’ve got a bunch of dead limbs in the back yard to get down while I have the lift. I also want to pick through the wood and get some good pieces for the wood turners who setup by our forge during festivals. The maple has some good spalting and the mimosa has some good color (and I heard it’s good for turning?). There was was good burl I saw as I was cutting, but I’m not sure I’ll find it again. Keep it fun, David

-

I usually make mine from 1/2” square bar with an inverted pyramid preform, forge down on the diamond, and draw width with the peen. Keep it fun, David

-

So that’s where my short term memory got off to…

-

Now that’s good! Certainly made me laugh out loud. (Not sure that it will help with supporting the jig block though.) Keep it fun, David

-

To bad I don’t have a lathe to make custom posts for it… Well, I don’t really have space for a lathe anyway. Keep it fun, David

-

Last night a long awaited fixture plate was delivered. (Long story of how I came across it…but no cost.) 30”x15”x6” 4140 pre-hard material with 5/8” threaded through holes in a 2” square pattern. Now I have another project on my to do list: make a hefty stand! Keep it fun, David

-

I would stay on the smaller side for the shop vacs. Scale and grinder dust gets heavy fast! Keep it fun, David

-

Looking for someone to make a pendant

Goods replied to BHUMP89's topic in Northwest Ohio Blacksmiths

If you’re wanting to support a local smith, you could post to the “Indiana Blacksmith Association (IBA)”Facebook group. I’m sure one of the guys there is jump on it. Expect the same questions, so you may want to put all the information in your first post. Keep it fun, David (IBA member) -

For file guides, I saw an interesting trick on YouTube. The person took a cheap ceramic kitchen knife and cut it with a diamond abrasive wheel to make the faces of the file guide, which he epoxied in place. I’m not sure how long it will hold up, but it look like a good idea… Keep it fun, David

-

I agree on the hat rack, but again it’s not my style. I am really drawn to the clean lines and simplicity of the crosses. Keep it fun, David

-

If I had to guess, I’d say they were MiG welded then wire wrapped. I like the idea of slit and drifted with a heat shrink fit. Not sure what to think about the hanger. It’s just not my style… I would agree with you that it needs a little more of something. Keep it fun, David

-

Keep in mind that using acid to dissolve coating that may be hazardous make the acid itself hazardous waste. If the coating is cadmium, it could take a lot stronger acid to dissolve it off. If it does the waste created is much more hazardous than if it was hexavalent chromium which is your typic yellow zinc plating that is pretty nasty in it own right. Keep it fun (and safe), David

-

What did you do in the shop today?

Goods replied to Mark Ling's topic in Blacksmithing, General Discussion

Dave, the demo was at Fort Vallonia Days in Vallonia, IN. John/George, I have never setup at a craft fair. So far, I have only done sales at demonstrations and only if sales are allowed or even expected. Either way, I would be traveling to and packing a lot of gear, the inventory is minor compared to tools and materials. So, the sales are a nice benefit that goes a long way towards offsetting my costs. Personally, I have received many opportunities for commission work, but passed most of those asking to the other smiths who are more suited to commission work. Between work, family, and other responsibilities I can’t always guarantee time in the forge. At this point I’d rather forge the items I’m interested in to my liking and hope that someone would have interest in them, if I’m willing to sell them. Keep it fun, David -

I picked up a patina forging in the sun this weekend, although its not what I would call “rainbow”. Keep it fun, David

-

What did you do in the shop today?

Goods replied to Mark Ling's topic in Blacksmithing, General Discussion

George, it really felt like the sales were lower that last year for me. The smith I was with seemed to be doing pretty good. However, when I got home and counted the revenue, I came out a little better that last year’s total. I think the main difference was having more inventory, so even with better sales, I had more to take home. Of all the items I forged during the demo, only one of the fire pokers were left unsold. Honestly, these events aren’t about sales for me. The main reason for me to attend is the demonstration itself. The sales are just a bonus. (This is only a hobby for me, and I’m really not wanting to take the enjoyment out of it.) Keep it fun, David