-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by sfeile

-

I happened to have some plate lying around so I just built a little box for mine. The top is not welded on, but just has tabs to hold it in position. I am going to order some Plistex to line it with to improve efficiency and durability, but it has been going strong untreated and no mortar for 7 or 8 months now. The hard brick in the front is just a "table" for resting long work or the piece I use for my front door on.

-

Mine may not be the approved way or the best way, but I'll offer a suggestion as to how I would do it with little experience. First, put it in the fire and anneal it. Get it softened up and as straight as you can on the anvil. You said belts, so I'm assuming you have a belt grinder. Use the flat platten and get the sides flat and clean. Check your thickness as you go and make sure to keep it consistent. Then take some dykem and paint where you want to make your plunge grind and paint the cutting edge. If you don't have dykem, use a sharpie and color it all in for the same effect. Now scribe your plunge lines and the center of your cutting edge. If you aren't doing a full "V" grind, mark where you want your bevel to stop also. Then either take your angle grinder or a 36 grit belt and start hogging your material down. Clean up your profile and get your bevel roughed in. Once you get your edge to about a dimes thickness or so and everything pretty much the way you want it. Then while it's still soft, drill your pin holes for the scales. Heat treat and temper it, then do your finish work. It is quicker to hammer in the bevel, but if you don't have a lot of practice at it, you can get off centered very easily or have a bad strike leave a deep hammer mark that won't come out.

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

That's looking great 58er! -

I wish I lived near you guys and your amazing scrap yards.... I have 2 near here. One in NY state that says NY state law prohibits them selling anything that has come in. I don't know if that's true or not, but bottom line is they won't sell. The other one is in PA, but I keep getting told to "talk to the owner". Apparently there are 4 owners and none of them are ever there. I did find one auto salvage yard that will pull a few things for me occasionally like springs or axles, but that's the best I've found.

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Das! -

Excellent work!

-

You are right on the date. Nicholson bought them in 1966 and took over or eliminated the products they had. As far as the cut of the file, Simonds still makes one like that. It is called a Multi-Kut file. From their literature: "The “world’s most versatile file”- combines the best filing features of a Flat file and a Mill file. Remove material faster while creating a smooth finish! The combination of coarse teeth and a double “chip breaker” groove cut into the file allows this product to do the work of a Flat file and a Mill file - 2 in one! Feature available on Simonds Flat Files and the Flat side of Simonds Half Round Files!"

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

-

-

Coming along nicely Mike!

-

I may be wrong, but I read frosty's post as dripping with sarcasm except for the last line. I believe he was insinuating that the guy selling was just being a snobby jerk, and not directing any animosity towards you. If he is asking that much for something it shouldn't be that big of an inconvenience to verify what they have.

-

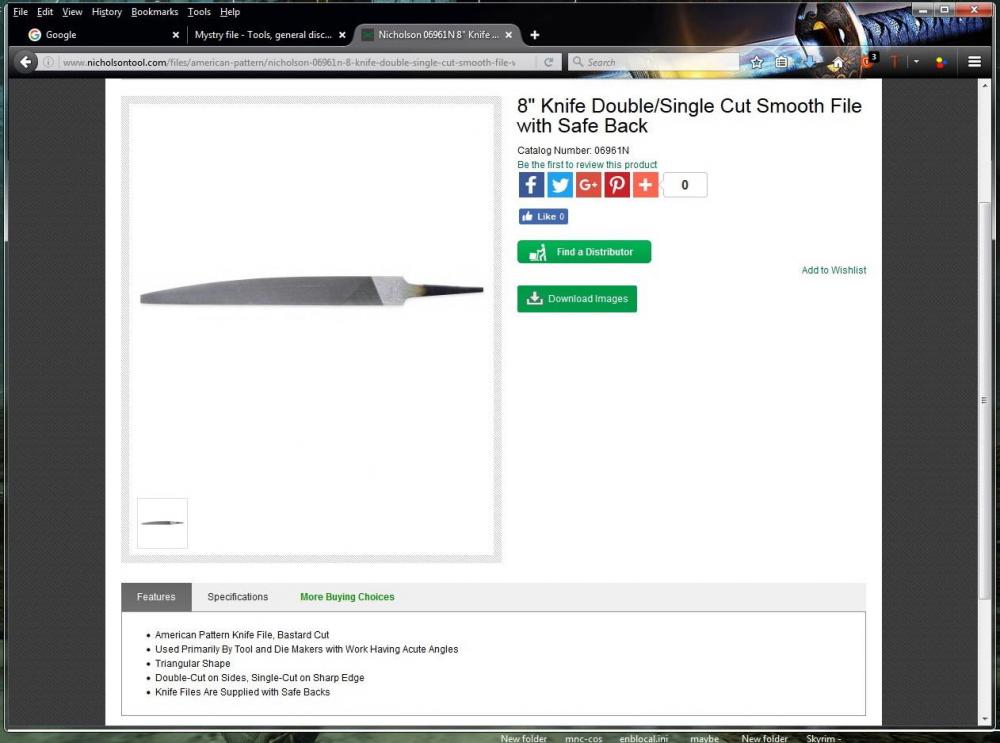

That is called a Knife file with a safeback. They are normally used by tool and die makers. The smooth edge or safeback is to keep from unintentionally marring the workpiece.

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice one Lou. I smoked a pipe for years and had never seen a plug cutter in person. It wasn't until shortly after I got asked to make the first one that I saw two in the same day in person. Both the same style as yours. Still haven't seen more than photos of the style I was asked to make though. I just did a "well that looks close" kind of thing. Looks like it's going in a very good direction to me Scott. Nice work. -

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you very kindly Mr. SLAG. -

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

Got some handle scales and finish applied today on the plug cutter. Still need to sharpen it and make the post for mounting it, but it's just about done. -

Found a new replacement anvil!

sfeile replied to windancer's topic in Anvils, Swage Blocks, and Mandrels

Ugh... I'm growling under my breath and drooling at the same time...... Great score Dave. -

Hi Steven. First thing, a photo would have been a little easier to look at instead of a .mov file, but I see it. I do agree with JLP. What are you going to use it for? Use can help determine a lot of things. Handle geometry, belly/no belly/reverse belly in the blade, grind geometry, blade thickness.... I will offer my thoughts though since you asked. Remember, I am not an expert these are just my thoughts. The design you have circled has too much sweep in the handle. In my opinion, there should be a straighter axis along the spine for that shape of blade. (Spear point, clip point etc...) That much sweep makes a good chopper, but you want either a straight edge or reverse belly like in the fist sketch. At only 8 inches OAL, that would be a pretty light chopper. With a deep belly like in your last sketch combined with that much sweep in the handle, you would have a very small sweet spot for chopping. I think (again only my opinion) that it will also make it difficult to have good control for slicing and normal cutting tasks with that much angle. It puts your edge out of alignment with your wrist and isn't very ergonomic. I like the blade shape for a general purpose knife. It leave you a lot of options with a good point, moderate belly and slight recurve, I would just straighten out the handle a bit so it is more in line with the spine axis. Not board straight, just not as steep of a curve. I would also add a choil for sharpening if it was one I was doing.

-

Common Beginner Mistakes

sfeile replied to Ridgewayforge's topic in Blacksmithing, General Discussion

Thinking you can do some grinding on a second project while the first one is heating........ -

Do you need my address so you know where to drop the press off? Great scores, both of them.

-

Going to one-up me aren't you? Can't wait to see it all together. I've been dealing with Tru-Grit for belts. Very reasonable and really fast shipping. And the ceramics are definitely worth it! I haven't tried the Blaze ceramics yet, but the other ones that they carry are great. I should have gotten more of them.

-

Very nice Mike! I get one of these orders done and I think I'm going to give her a shout. That looks very well done.

-

Is that a rebar shear?

-

What did you do in the shop today?

sfeile replied to Mark Ling's topic in Blacksmithing, General Discussion

That's why I tried the coal instead of the gas. I set it outside the door. Still about 90 inside though. I got the baby hammer out to move it to a manageable thickness. (8 pounds)