-

Posts

219 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 4elements

-

Hi ItsSwanny, I'm in Granite Falls, WA and believe me you are not alone in this area. We have a very active regional blacksmith association, Northwest Blacksmith Association or NWBA and we meet monthly in Longview, WA. I am currently making my third forge similar to a JABOD as Charles mentioned. For mine I'm using a washtub rather than a wooden box but all the same otherwise and I'm out maybe $20 so far. You have Seattle as your location and mention Country Village which is in Bothell, there are classes available in Seattle, Anacortes, and other places around here and you have plenty of resources for tools and materials too. In the Seattle U-district on Roosevelt street is a hardware store like no other with an amazing assortment of tools. In Everett is a steel company that sells drops and shorts for a per lb. price. There is a place in Clearview that sells recycled steel, I have driven by but not stopped there, but by the looks of it you might find a suitable anvil there. And as for London pattern, I just passed on one in Longview last week because i was more interested in a 5 in post vice for $100. Welcome to the addiction, there are lots of people on this forum and in our area ready to help. You can PM me if you want more details.

-

Welding Flux video (Hydrous to anhydrous)

4elements replied to jlpservicesinc's topic in Fluxes used in blacksmithing

It Will have to be tried to see if there is an advantage. I imagine ease of use and maybe less flux dripping on the forge floor -

Welding Flux video (Hydrous to anhydrous)

4elements replied to jlpservicesinc's topic in Fluxes used in blacksmithing

Perhaps an open mold coated with 600f silicone? -

Welding Flux video (Hydrous to anhydrous)

4elements replied to jlpservicesinc's topic in Fluxes used in blacksmithing

JLP have you ever tried casting the molten borax into rods and rubbing it on hot iron like a pencil? would that work? This thought just came to me last night but I haven't tried it -

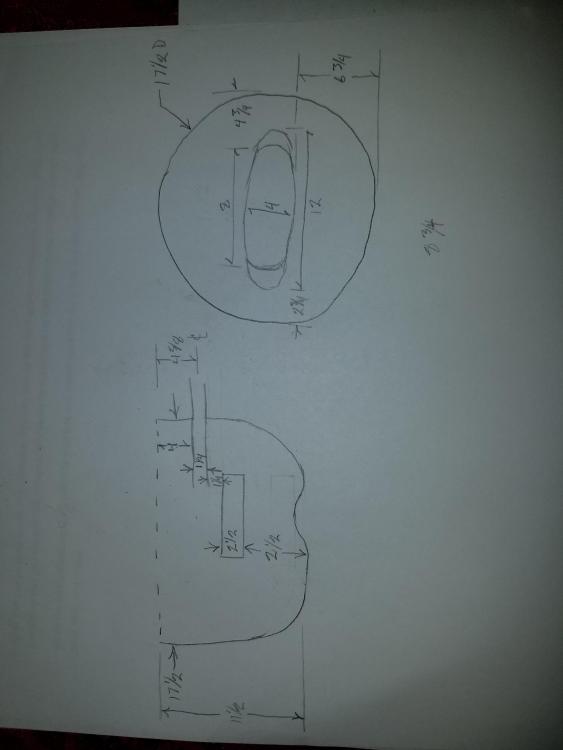

I am now in process of making a washtub forge. the fill is clean raw clay with sharp silica sand at about a 40% clay to 60% sand, by guess. The clay is as I dug it up and is damp enough to kneed into the sand. I am following the recommendations from the solid fuel section of this forum for various dimensions. Picture 2 is a 2 1/2" thick fire brick for the bottom of the firepot. Picture 3 is the 1" black pipe for the tuyere. I wrapped it in waxed paper to keep the clay from sticking so I can adjust it if the end burns or it needs replacing. The next three are of combining the sand and clay. Last is a tryout to see if I have mixed enough (not yet). That's as far as I've gotten as yet. So far, just the tub and the pipe have cost me anything. I had the rest already.

-

OK, here's the trough forge I mentioned above. I haven't tried using wood to fire it, just charcoal. I figured that the charcoal from burning wood is what the fuel really is anyway. Like I said, I'm not thrilled with it. It isn't an exact copy of a Whitlox, I was using material from my scrap pile. The tuyere is square tube with a series of 3/8" holes and a baffle to adjust the length of the fire. Whitlox has a round tube with another tube inside with a series of milled slots matching the round holes in the outer tube. each slot is progressively longer around the circumference so rotating the inner tube opens more air holes in the outer tube. Too complicated for me to make. the air supply on a Whitlox is from the rear, which is different from mine. I didn't track cost in building it. The "V" shape doesn't allow you to make a deep fire and all the ashes slide down the slope and block the air. This may be some flaw of my own making but I don't think I'll try to improve it at this time.

-

I can only post pictures from the home computer. It doesn't work with my phone. I'll do it as soon as I can

-

I have also built a similar forge . I use charcoal instead of wood. I find the design problematic since the ashes slide right down the bricks and clog the tweer. it takes a lot of fire management to keep air flow adequate in the spot where you are working. I'm working on a washtub JABOB instead.

-

That disappeared steel became iron oxide. There is a way to make steel appear from iron oxide called smelting. Sadly it is a much more difficult and involved process than the original disappearing act. Someday I hope to try it but not with any steel I've "dissapeared" first.

-

Auto supply stores carry an assortment of exhaust pipe repair pieces that will assemble with U- bolts, no welding, no threading. I haven't seen a T but maybe you could find a Y. They also have flex.

-

Daswulf, I've seen that too where the bark is intact. I'll be looking for the ones that have damaged bark or are blown down from storms, anything that opens the wood to the flames. Then we will see if charcoal is clean, or mixed into the soil and duff

-

Jasent, Charles thanks for the responses. I was meaning the way the trees burn in a forest fire rather than the quality of the charcoal. It seems that a hollow tree burning through the center makes a pile of clean coals that are easy to collect. I have to get out and see what happens to a solid standing tree or a fallen dead tree to know if charcoal is practical to collect from our local forest fires.

-

I like that idea! We have wild fires here too but mostly in mountainous terrain. I'll have to go hunting next summer. We just had a white Christmas, so I have to rely on bagged charcoal for a few more months. our trees are large conifers, so I don't know whether they burn and char in a usable way.

-

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

-

You are correct and i must have misread the directions (it was a while ago) . I will be moving mine to a proper location. Multiple web sites I've looked at say that it mixes with air rather than rises even though it's lighter, so head height would be correct. I'm sorry for the faulty info.

-

I have a CO alarm in my house, mounted near the floor as per the instructions. CO is heavier than air and will fill a space from bottom up. With the alarm at head height, by the time it chirps your space is already 1/2 full of CO and it is dangerous to bend over to pick things up from the floor. please, for safety 's sake install it low

-

hollow? 1/4" thickness? no substantial mass anywhere? That's an insult to anvils everywhere when that honorable name is used for the likes of that. Even cast iron is less rediculous, at least in that it has mass.

-

I just saw a headline today, someone wants to create an AI deity

-

does the vibration affect it, make it fall or shake it out of alignment?

-

How to make a perfect forge weld, every time.

4elements replied to Glenn's topic in Blacksmithing, General Discussion

Were!, we don't need no stinking were! Here in the great north wet we have sasquatch! (See if you can catch me) -

Welcome Will M. Just to let you know, Laughing Bodger on this forum is a neighbor of yours. Lives in Taree too. There are quite a few smiths from OZ, they even have their own registry IIRC.

-

Silicone Anvil Base Question

4elements replied to MC Hammer's topic in Stands for Anvils, Swage Blocks, etc

My blower is loud too . I use molded earplugs on a string, not the foam ones. They are washable and reusable and cheap, besides easy to use/ insert. -

I have a washtub of ashes for annealing right next to my quenching oil. It seems to me that might work. Non combustable, powder, quantity enough to smother. Do you think that would be adequate?

-

Noob Needs Help <split from HIjack>

4elements replied to STC4476's topic in Smelting, Melting, Foundry, and Casting

First, the terms you use in your post show that you don't have much understanding of what you're attempting. Smelting is not melting. Melting ferous alloys without proper training and equipment can KILL OR MAIM YOU as well as anyone else nearby. You must NOT go into this QUICKLY or ALONE! Plenty of members on this forum can advise you with years of experience, but they will all give you the same warning.