-

Posts

219 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 4elements

-

Ti is also a flammable metal similar to magnesium. When drilling you have to use 600 rpm or less for a 3/16"drill bit or you will ignite the chips. I've done that, just like a mag fire starter. It's not something I would consider forging without safety research.

-

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

Daswulf, I'm just fortunate to have some people close enough to reach out to. I got to know them through this forum and got comfortable enough to contact them. Glad I did, now we can see what we can build as friendships. -

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

I met a couple of smiths in person whom I had only meet online. on Thursday I met Ohio. We chatted a while before I went to work. I offered her some steel I thought she could use to make an improvised anvil, and she have me a jar of her homegrown honey. On Saturday I invited Shady McGrady to my place and we forge welded some chain links in my charcoal forge. I enjoyed meeting both of them. -

Cold setting 300 series stainless rivits

4elements replied to Charles R. Stevens's topic in Problem Solving

I don't know about stainless, what about monel? I've done those on aircraft cold with a hand held rivet gun and bucking bar -

Junk!?JUNK!? That's resources

-

I agree with Thomas Powers. My suggestion was only if you are set on trying stone. There is a whole thread here on improvised anvils.

-

Just finding granite doesn't mean it will make a suitable anvil. Even though the name is the same, stone from different areas can have very different qualities. Some is solid and strong and some is crumbly and soft. Many other stones are like that too. Basalt might work, but only if it's the unweathered columnar type. Most of the basalt I've seen is too fractured to use. While not knowing what you have in your area, i would find a stone you think would hold up to being pounded and hit it numerous times with a hammer, in a manner similar to striking metal, to see how it reacts.

-

Is there a reason that a nail header doesn't have a short hollow hardy shank to keep from bending nails rather than being able to slide around over the pritchel hole?

-

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

Thank youLutz, I'll look into that but since I'm going to the NWBA swap meet this weekend, I'll wait to buy until after I've seen what's there -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

Hi Denise, the delamination i saw, if that's what it is, looked old. I couldn't tell that it was an active crack, also its in an area that would get little hard use. I didn't think $350 was reasonable, $225 is better and since the ring test didn't give a hollow sound, it then becomes a question of is it cheap enough to take a risk of further delam. As far as repair goes, all I can say is maybe. I have no experience in that kind of welding, but a small bead with proper care might work. It would be on the side, not the face, still some risk. Going to see for yourself doesn't obligate you to buy. -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

But I could have told people that the corner broke when or landed on Wile E coyote -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

I passed. The damaged corner also had what looked to be a 2" delamination crack though it didn't sound hollow there or anywhere and the rebound was a consistent 80%. I just felt $350 was too high to take a risk of crack propagation even though that may have been unlikely at that spot -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

I'll be at the NWBA swap meet, but at the conference in May, all I saw were 300 lb monsters. Way overkill for me. The one I have will hold me for awhile, I was just interested in this one as portable. If i find any more defects tomorrow than what i see in the pictures, I will pass. -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

Marc1, I knew $450 was too high but I'm using a cast iron ASO that I did some improvement on. Its still only just adequate, if even that in the long term. 75 lbs IS small, but it's also more portable if I want to do demos. DanL. I haven't been searching, so I haven't been aware of new anvil prices around here. The only place I know of that carries anything worthy of the name anvil is Harry's leather shop in Everett. Their prices are way out of my range. This listing came to my attention thru NWBA, so I checked it out. Do you know of other suppliers around here? Thanks for the input. I'm not falling all over myself with this, which is why I'm looking for opinions. -

What's this 75 lb PW worth?

4elements replied to 4elements's topic in Anvils, Swage Blocks, and Mandrels

thanks IF&C. I offered 300, he came back with 350, I said maybe depending on examining it in person. The pictures are limited in usefulness -

Posted on Seattle CL, blacksmith anvil - $450. I'm going to see this tomorrow am, I've already contacted the seller and offered a lower price depending on testing and condition. I'd appreciate opinions on a price value. Thanks in advance

-

Hot toluene. I was going to try to extract sulphur from rocks once and that's where my research took me. It doesn't seem safe to me to heat a highly flammable liquid like that so I never followed through

-

Hi Shady, look at the post "questions about my first forge" by cavpilot2k, that's what I was talking to you about earlier today, what frosty said.

-

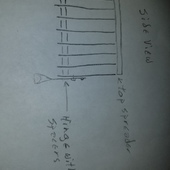

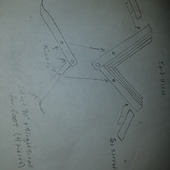

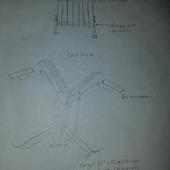

i'll try again with the sketches I noticed above you mentioned a pan to go under the grate and the folding V shape. The example Glen gave has a horizontal bottom which leaves a bed of coals in close proximity or contact with the wood above. The V won't allow that to the same degree. You could still get a folding design that would approximate the one Glen posted, it would just have 2 fold pivot points, and the end pieces could be extended a couple of inches to make legs. spaced at 3" it would be light and easy and with your pan under it set on folding legs you wouldn't run afoul of the burnt grass objectors.

-

I did you all a favor and set the bar really low

4elements replied to Ohio's topic in Blacksmithing, General Discussion

I'm sorry i got the dates mixed up for the NWBA meet. It's not next weekend, its Oct 27th thru 29th -

I did you all a favor and set the bar really low

4elements replied to Ohio's topic in Blacksmithing, General Discussion

Don't let the comments discourage you. Leaves themselves are so variable, including at times deformed, that if the average person can identify it, it's good. It only gets better from here. And i don't think anyone here wants to put a damper on your enthusiasm. some things are best made with uniformity, and some are best with uniqueness. I'm glad you have that neighbor smith to mentor as well. Forge on. -

I did you all a favor and set the bar really low

4elements replied to Ohio's topic in Blacksmithing, General Discussion

Glad to see you back Ohio. I will be going to Longview for the NWBA Swaptoberfest and mini conference that Swedefiddle mentioned, which is next weekend. If you decide to come, you'll find everyone is just as friendly and helpful as here on IFI. I hope to see you there. -

Hi Frosty. since you didn't include a drawing, and my brain's text to visual translator is iffy at best, I've made a sketch of what I think you are talking about. correct me if I am wrong. I would still opt for 1/2" to 3/4" spacing. Instead of individual spacers you could make a J bend on the bottom of each piece and put the pivot hole through both sides of the lower end of the J.

-

I got it now. Well since just holding the wood isn't much of an issue, it seems to me that keeping the coals from falling out while letting air in are the main constraints. Since the top of the fire won't have much coals, id think variable spacing with it wider at the top and about 3/4" at bottom would serve. Just my opinion, take it for what its worth.

-

I would copy the spacing from a barbecue if it was for grilling, 2 or 3 times that for coffee pots and pans. Maybe one side of each spacing.