-

Posts

219 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 4elements

-

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

I recently visited friends in Bardstown KY, and went to antique stores. I asked for their rusty junk and looked for forge welded things. I got a nice strap hinge half and an adz head. Cheap too. I came back home and went to the NWBA conference where a guy from Montana had a trailer loaded with WI salvaged from a bridge. If you want it, you'll get it, it's around -

Hello from Granite Falls,WA. Don't wait to get more active. I went to an NWBA meet a while back, and at the time I needed a post vice. A guy came in while I was talking about that and said his friend who buys out storage units had some things to sell. He laid out 3 pictures, anvil, swage block and post vice. I got the 5 in complete and working vice for $100US. Waiting may mean losing opportunity both for tools and the fellowship of other smiths.

-

Boattlebot, I start my coal forge with a mapp torch too, but I clear the grate and put a hand full of lump charcoal on it. I light the charcoal with the torch and begin to give it air then I pull in coal a little at a time until the fire reaches a good forging state. This way produced little smoke as opposed to lighting the coal directly, and in my opinion is more effective than using wood, paper, kerosene, etc.

-

Very cool, but where did that darn dog get off to now?

-

GARRRRRR!

-

Anyone in NW Washington?

4elements replied to Nobody Special's topic in Events, Hammer ins, Where to meet

Hammer monkey you give me way WAY too much credit. Welcome nobody, I'll be at the NWBA conference for all three days. Join up and come down, it will be so worth your time. It's a 3 hour drive for me and I know out would be longer for you however the opportunities for learning, connecting and tailgating are fantastic -

Shop Cleaning Question - Magnetic Floor Mats?

4elements replied to Meridianfrost's topic in Blacksmithing, General Discussion

How about a magnetic sign blank, like those that some businesses use on vehicles. Apply it to the floor magnet side up with double stick mounting tape. You should be able to get one at a sign shop. I don't know what they cost but I'm sure it's not near the $2k range. -

What did you do in the shop today?

4elements replied to Mark Ling's topic in Blacksmithing, General Discussion

I rebuilt my coal forge. The fire pot was too deep so I added a 3/16" plate to raise the floor and added a bullet grate. it works much better now. I also went back to the bellows instead of the hand cranked blower. I'll save that for a bloomery that i hope to build someday. -

Not treating a cedar handle

4elements replied to Hunter Copelin's topic in Finish and Polish for Knives

The color of the rough unfinished wood and that you cut the tree yourself. I once made a chess set by cutting the red from the white. Nice smell too -

Not treating a cedar handle

4elements replied to Hunter Copelin's topic in Finish and Polish for Knives

Hi Hunter, I was born and raised in Oklahoma and have used that wood a little, but note that there are several trees that are called cedar. What you have is actually juniper and i expect it would do fine with proper treatment as was suggested. True cedar like the western red cedar we have here in washington state where I now live, is much softer as is the eastern cedar from Maine. Those I wouldn't use. -

Thanks Slag and Ausfire, I have a copy of Robert Service poetry and enjoy many of them. I memorized The Cremation of Sam McGee and recited it many times to Boy Scouts at winter camps. I also recommend "How McPherson Held the Floor" and "The Baldness of Chewed Ear".

-

There are strange things done in the midnight sun by the men who moil for gold. The arctic trails have their secret tales that would make your blood run cold! Robert Service "The Cremation of Sam McGee"

-

Is that what "pound for pound" means

-

Hi Andrew. Since you are in Washington State have you considered joining the North West Blacksmith Association? This forum and the smiths here are a wonderful resource but there is nothing like having hands on help. Even pictures don't always tell the whole story since they aren't dynamic and only show one perspective. I try to get to the NWBA meets almost every month in Longview, which isn't that far from you. You could meet a bunch of smiths in person, and if you brought the forge the help could be very profitable to your smithing endeavors. I built a JABOD style forge and posted it as "Just a tub of dirt", took it over to Shady McGrady's house (he lives near me) and he had a brake drum forge. We were burning Cowboy brand charcoal and both of us forge welded chain links. Shady posted pictures too. I have used coal and while it takes more to light, your frustration may come from not knowing what to expect and how to manage the fuel, or maybe the need to make an adjustment to the forge, some things a little in person help might overcome easily.

-

Yes, get well Frosty

-

I'm glad to see you back. I know how life can get in the way. I've had a rough couple of weeks too. I can call you and share my thoughts on a JABOD and an improvised anvil from the steel i gave you. I'm at work now so I'm limited for time till I'm off

-

Andrew, do you have a source for good smithing coal? Not all coal is equal. NWBA has a member who sells coal Coke and charcoal. You can use coal from other places but some types take more fire management, won't coke decently or produce excess clinker.

-

Andrew, I was just looking at your other threads and I'm wondering if you've decided on the fuel you are going to use? The type of air supply can be dependant on the fuel. Charcoal needs air only when you are heating metal, so manual blowers or bellows are not going to waste fuel like continuous electric powered blowers. However coke requires continuous air or the fire will go out between heats, so electric is the way to go. Different types of coal burn differently as well and so will affect the choice too.

-

Marc, you and Thomas are both right since you are on the other side of the date line and the Egyptians made beer so I'm with Thomas

-

Hi Andrew, as Glenn said the Northwest Blacksmiths Association is a great resource. Our website is blacksmith.org and we meet monthly in Longview. Your location only gives Washington state, so I can't tell how close you are to me but we have members all over from Oregon Washington Idaho and even BC Canada . I think you'll do better with a charcoal forge in your location since coal smoke can be obnoxious in close quarters. I just built my 3 rd forge as a JABOD, which you can see in the solid fuel section under "Just a tub of dirt". Same concept and portable. Your BBQ would likely work for this style. I have to go to work now, but you can PM me if you want more local info.

-

Just a Tub of Dirt, photo heavy

4elements replied to 4elements's topic in JABOD - Just A Box Of Dirt

Here's a couple of pictures of the first fire. I didn't heat any metal, this was just to see how it burns, and to fire the clay and maybe vitrify the firepot. when I get a stand built I'll do some forging. -

Just a Tub of Dirt, photo heavy

4elements replied to 4elements's topic in JABOD - Just A Box Of Dirt

JHCC , yes I will build a frame with a tray. Daswulf, you are right. Charcoal is my preferred fuel. -

I posted "Just a Tub of Dirt" with all the pictures I took in the solid fuel section. The build took about a day and a half, and around $20. I had the sand already, so I didn't include that cost since I don't remember that far back. I haven't built a stand yet, or a fire. I'll post again when there is more to show or tell.

-

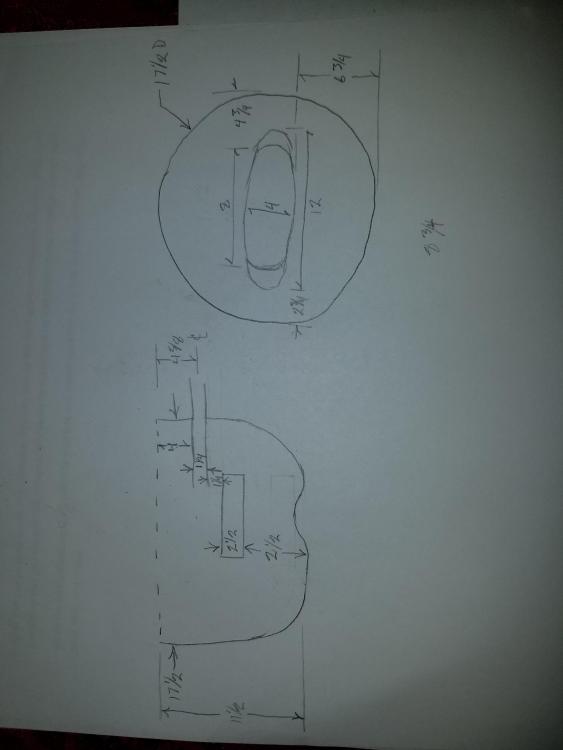

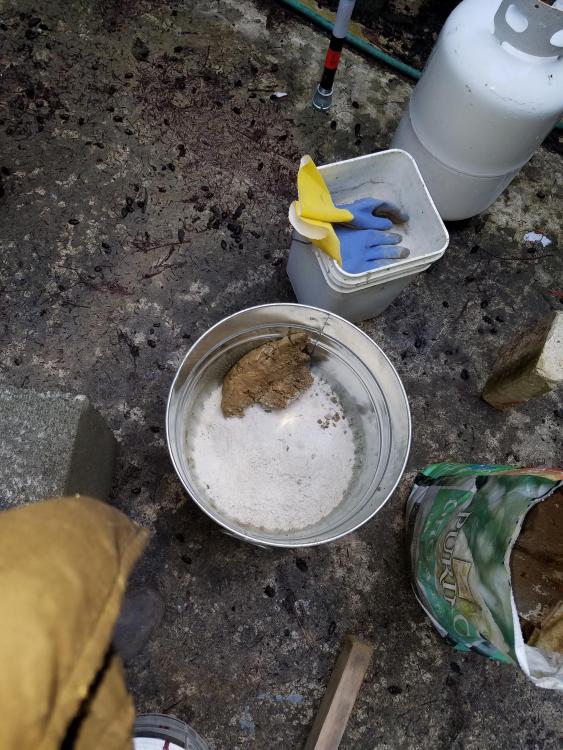

I am building a new solid fuel forge and since it is an variation of the JABOD I am posting pictures of the build. This is built in a bushel size wash tub, rather than a wooden box. The fill is mostly raw clay I dug on my property mixed with sharp silica sand. I did put some plain soil in the bottom under the fire brick so I could conserve the sand clay mix. My tuyere is 1" black pipe which I wrapped in waxed paper to keep the clay from sticking to it. This is to allow the pipe to be pushed into the firepot as the end burns off or to be pulled and trimmed as a consumable. We'll see if and how that works. I followed the suggested dimensions for a JABOD found in this section of the forum. Here is my working sketch. The wash tub with the firebrick for the bottom of the fire pot. The Tuyere wrapped in waxed paper. The mark on the tub is for the hole. The galvanized fitting is to adapt to my bellows. If that end gets hot I'll remove the zinc. I don't know if that will be the case yet. Mixing the sand and clay. I ended up kneading the clay into the sand with my hands. That was the most time consuming part. There probably is a better way. checking to see if I made enough (not quite). soil to make up the difference, going in the bottom. screening out the rocks. soil in the bottom. Next the fire brick. Adding clay sand mix. Drilled the tuyere hole. Approximate location for the tuyere. continuing to fill. nearly there. final shape. Coming soon, a small conflagration.

-

I'll do that soon Charles, right now I have to clean it off of the front porch before my wife gets back

.thumb.jpg.ab00579be1308e0a973f0e9688a71572.jpg)