-

Posts

189 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BlasterJoe

-

This was one of two I made. The other one turned out better but cracked when quenching. The handle looks like it has a crack but is just a cold shut from drawing it out with the teeth on the rasp. Next time I will defiantly grind out the teeth. looks pretty rough. Has anyone else made these and did you clean the rasp up more before forging?

-

Jhcc, did you see the other toys in th garage. Look at my profile. I do have to have a good excuse.

-

Aus, your scrolling work is always great. Do you just use tongs or do you use jigs and stuff?

-

Glenn, i looked it up again and you posted it a long time ago. The instruction were actually by Don Abbott. So thank you Don and thank you for sharing it.

-

Well here is my second attempt at a file knife. This time I followed the step by step Glenn posted. The instructions were great and definitely helped me produce a better knife especially the heat treat portion. Thanks Glenn. I had trouble having the colors run the way that was explained but my thickness isn't as uniformed as it should be. That also contributed to a slight bend in the blade. It holds an edge well and still sharpened easily. I made the handle from a cut end of a hammer handle. Used JB weld for the epoxy. Little mahogany stain and some oil on the handle.

-

The big one is just a 3/4 piece of mild and the smaller one was an old 3' long bolt I found somewhere. The sparks coming off it were pretty complexed but I'm not totally sure what it was. Just forged them out and cold water quenched and they stayed plenty springy.

-

Should have made one of these a year ago. Super handy and very easy to make. The one in the Hardie is a little big and doesn't leave much room for work. Maybe a good excuse to buy a bigger anvil?

-

What kind of ax is this?

BlasterJoe replied to BlasterJoe's topic in Axes, Hatchets, Hawks, Choppers, etc

It is sharpened on both sides but one side the bevel is a lot steeper than the other. One side the bevel is about 1/2 inch and the other a 1/4. -

Very nice Das, I've been trying them too but none that turned out that nice.

-

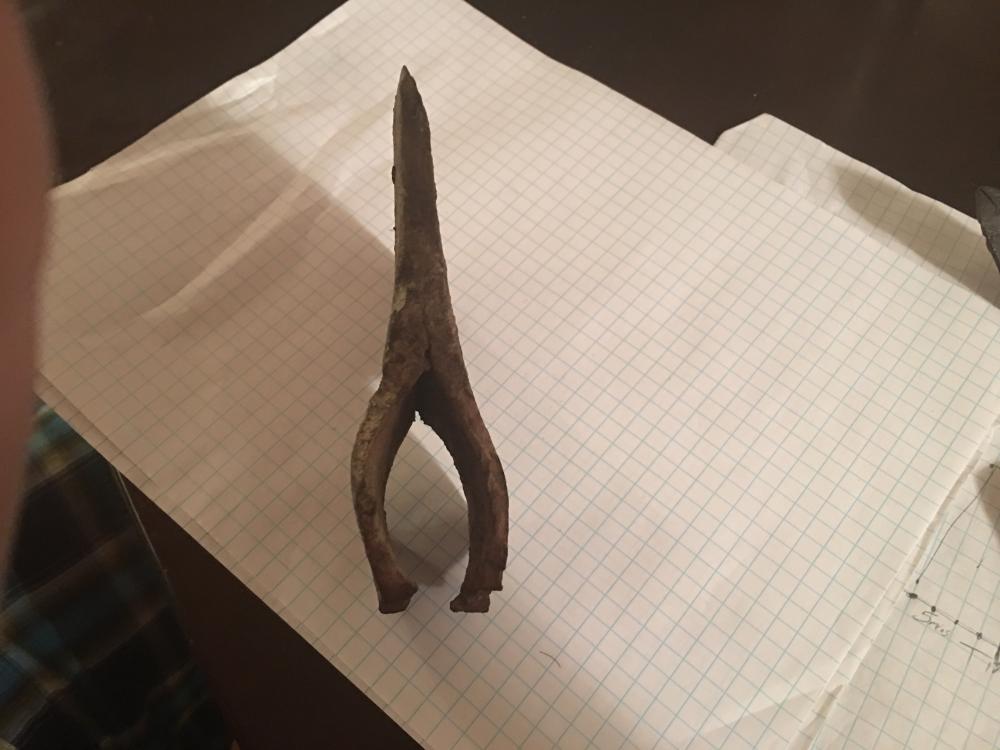

This is an old ax head I found on a metal detecting trip I made to an old local ghost town. I found it at the mouth of an old working. I know they used them for trimming timbers but I don't know what it's actually called. Looks like it was forge welded but I don't see a defined bit in it. I haven't taken a grinder to it yet. I am currently working on reproducing it in my own way. I will post more pics when I get aways into the project.

-

-

Thanks BCROB, I tried the horse head on the handle but I need more practice. It's a good quick gift for horse people.

-

-

-

I like how busy it is. Definitely pleasing to my eye

-

That's awesome. Great work!

-

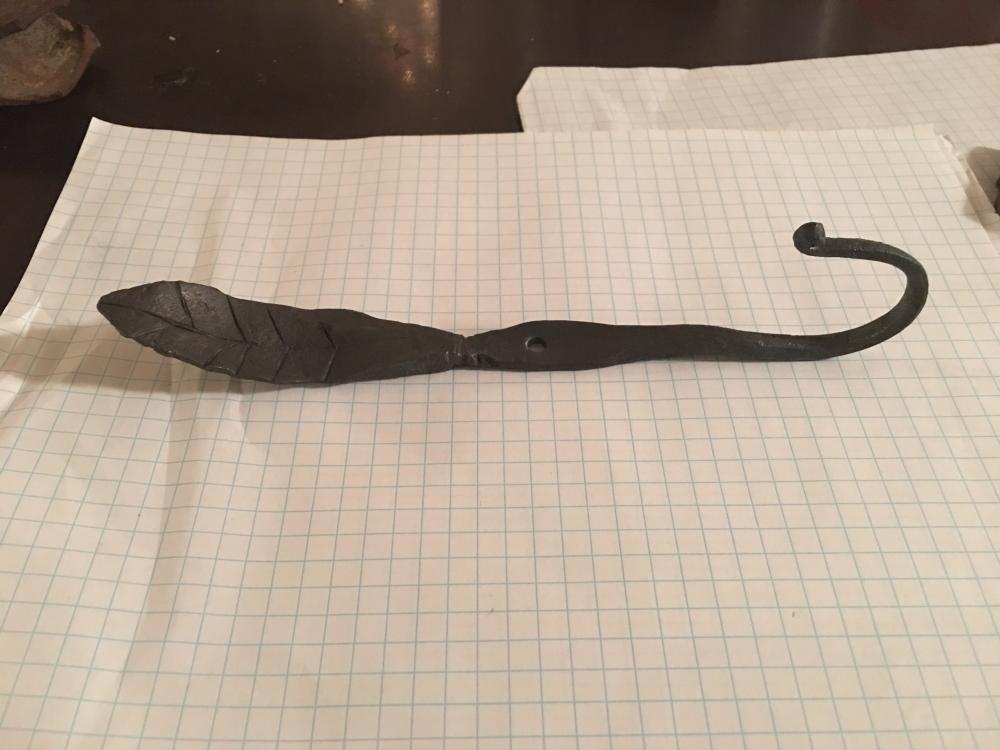

chain damascus drawknife in progress

BlasterJoe replied to bobasaurus's topic in Chisels, Gouges, Scissors, etc

Beautiful piece. What did you use for flux? -

That just have taken some serious time to draw that out. Like these guys were saying get some mild steel from the hardware store"not galvanized" and keep on hammering. Railroad spikes are good for a lot of different projects. Check for HC high carbon or MC mild carbon stamped on them. Do a search for rail road spike on this forum for ideas.

-

I tried my hand at a file knife. Actually one of the first blades I have made. I pretty happy with how it turned out. It was good enough to cut up the thanksgiving bird. I do still have a lot to learn about edge geometry. It took forever to get a sharp edge on it.

-

Hello all, Had a couple of firsts today. I actual punched out a plug! Never actual had that work out for me. Also I was able to drift out a decent size hole.

-

What do you do when.....

BlasterJoe replied to SkoobyNewb's topic in Blacksmithing, General Discussion

My forging playlist alot of Clutch recently I have been on a punk kick. Nofx pennywise and bouncing souls. Good speed for working. -

Absolutely stunning. Great work. How much does it weigh.

-

The crack happened pre drift. I was just trying to get the hole punched.

-

Hello all, I have been working on making my own hammer. This is my first attempt ever with something this big. I used a piece of trans axle I found and just kind of went for it. After about a day and a half of work it all blew up in my face. I think I need to make a better eye punch. I made a drift but figured I could just drive a cold chisel I made from an old pry bar. Was it spreading too much too fast? I tried to keep yellow heat when driving it but it did stick a few time and took some doing to get it out.

-

I have been thinking of making my first hammer. I only have experience with tempering some tools I have made from spring steel. I usually use cooking oils or used motor oil. What is the advantages of using water? does carbon level play a part in your decision? I looked around on the forum some but couldn't find anything definitive.