-

Posts

1,193 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

-Middle Tennessee

-

Interests

Blacksmithing, bladesmithing, ANVILS, shooting, woodworking, leatherworking, praise music, acoustic guitar, song writing, recording, music production, you get the idea...

Recent Profile Visitors

6,951 profile views

-

Here’s a recent custom knife I made for a friend. All stock removal except initially bending the stock to make the design fit. 1095 and canvas micarta. Going to a seasoned cowboy who primarily needs something to slash through bailing wire.

-

I was taking a stroll down some old RR tracks the other day (rail is marked 1920s I believe) and came across several quite sizable (pic is of the smallest one) blobs of what looks to me like molten iron that was poured on the ground many moons ago. My best guess is that they were from an intermediate stage of the iron industry, being transported for further melting/casting and rolled off the train, sealing their fate as useless but historically intriguing blobs of iron. Anyone familiar (or clueless) with the old (actually pretty new) iron-making processes want to weigh in?

-

I never buy new Blacksmithing tools anymore, but this evening I puttered around on a popular online smithing supply store looking for a hammer to give to a friend, and I was astonished at the prices for tongs. $100-$180 per pair depending on the style. Has there been a widespread increase in price over the last couple years or a bunch of bored people getting into smithing due to covid lockdown?

-

Best blade profile for cutting hay string?

C-1ToolSteel replied to C-1ToolSteel's topic in Knife Making

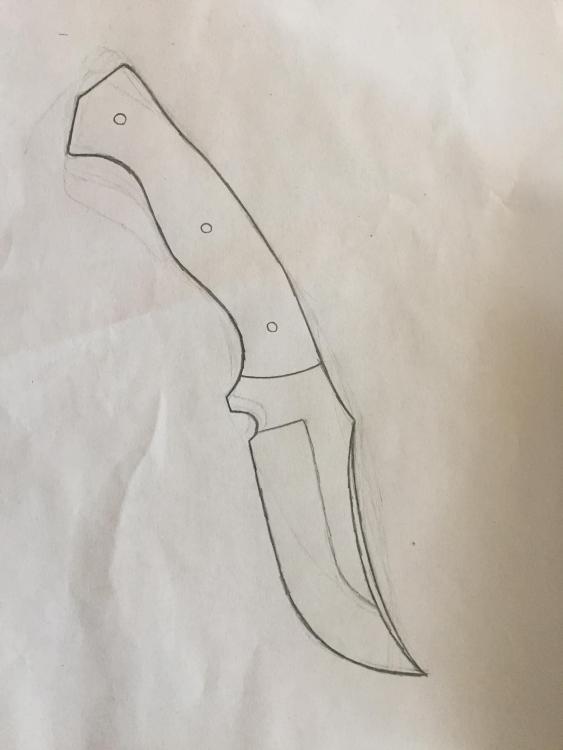

Thanks everyone for all the replies. I was thinking about doing something sorta seax or tanto inspired, but he wanted something much more like a skinner. It may not be the absolute best shape for hay string, but he loves the design I drew up, and I’m sure it will be used and abused for a million other odd jobs. I’ll post pics when it’s finished. -

Just a thought I’ve had for a while and was wondering what fellow metalworkers think. It seems like the more experienced I get at working with steel, the less I flip on the power switch to that cumbersome piece of cast iron. Angle grinder is so much more versatile for my personal needs, and having a good belt grinder or even a cheap 4x32 sander seems to cover everything I used to use a bench grinder for. Shoot, I’d rather clamp an angle grinder in a vise sometimes than use that chattery thing with a motor that always manages to get in the way of whatever I’m grinding on. So what do you guys think?

-

Howdy folks! A good friend of mine wants me to make him a custom fixed blade carry knife primarily for cutting hay string on round bales. He wants to be able to slash across the entire bale, so not looking for a hook shape or something that would be prone to getting caught. Any thoughts on the best design for a blade of this purpose? He was thinking about something with a blunt looking (but sharpened) tip, but I’m curious what blade profiles some of y’all would go with.

-

Thank you Frazer!

-

What it means to be a "Certified Welder"?

C-1ToolSteel replied to OnaMcD's topic in Welding/Fab General Discussion

I like the way Chris Willams put it - looking for someone who’s *qualified* but may or may not be certified. Of, course some specialized welding jobs with higher risk/liability will require certain credentials, but I think for the “general welding” you mentioned, whether or not you choose standardized schooling over good ol’ long and sometimes frustrating hours in your garage is up to you. I took a 1 year combination welder course in Tennessee which covers basic stick, MIG, TIG welding in various thickness and positions as well as plasma, oxi-torch, grinders, print reading, etc. I am now a full time welder, and although I can’t say my employer would’ve turned down a competent welder without a cert, getting the cert has definitely taught me the knowledge and skills to be qualified for a variety of welding/metalworking tasks. -

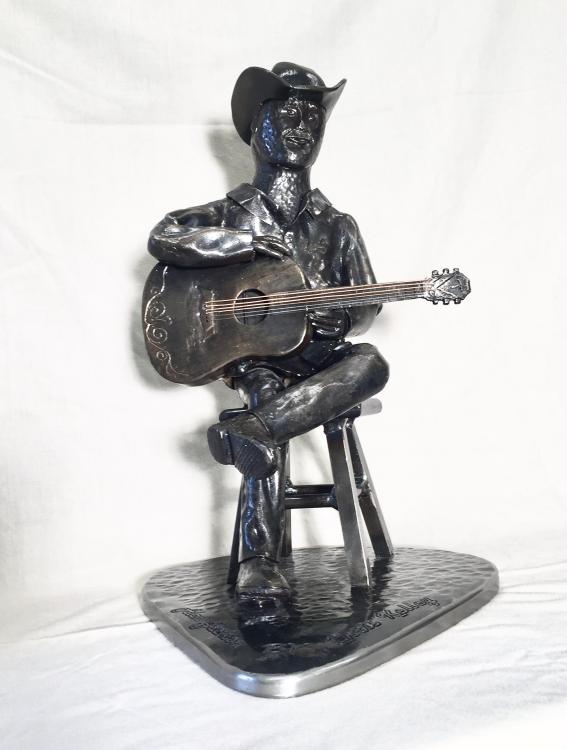

Thanks guys! Really appreciate it. Kevin Olson, the Guitar player is 16 inches tall.

-

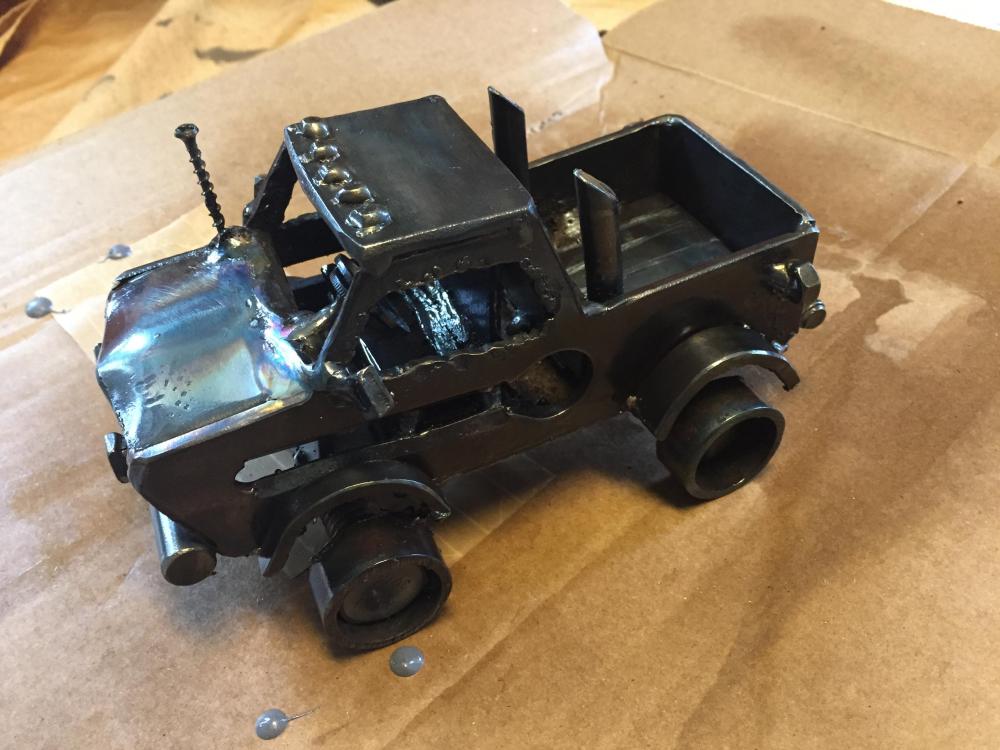

Hey all! Been forever since I’ve been on here, but looks like this is still the same great forum with a lot of the same great people. 2 years ago I decided to get certified in combination welding, and I’m now doing metalwork full time. Although, the welding I’m currently doing for a living isn’t art, I’ve been able to keep my artistic side alive with some side projects, so I thought I would share a few pics. Hope you enjoy.

-

Best Clear Coat for Complicated Sculptures?

C-1ToolSteel replied to C-1ToolSteel's topic in Finishes for Metal

Thanks for all the suggestions! I went ahead and tried Penetrol and I’m very pleased with the results. Brushes on easily without any dripping problems. -

I don’t know if it’s just me, but it seems like more and more people selling things online are going the “He who speaks first looses” rout when it comes to pricing their items. They just say “make me an offer” which invites the prospective buyer to send a conservative offer to which the seller replies “no lowballs”. Instead of getting offended at a low offer, why not just list the item a little on the high side and let negotiating do its thing?

-

Yup! Gotta do that heat treat and file test before shaping. Nice letter opener, though.

-

Best Clear Coat for Complicated Sculptures?

C-1ToolSteel replied to C-1ToolSteel's topic in Finishes for Metal

Thinking about trying Penetrol instead of an aerosol solution. Anyone here use Penetrol before?