-

Posts

189 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Round mountain NV

-

Interests

Hunting, Blacksmithing,

@Lock_Jaw_Forge on IG

Recent Profile Visitors

3,936 profile views

-

I did water quench it just for good measure. Aus It is a pity. I think it will be sturdy enough not hardened. I wouldn't go much thinner than an 1/8 inch round on the screw. I will let you know if we run into any problems as we use it. Rockstar, That's a good idea on the twists. its not the most comfortable right now so I might do that with this one.

-

-

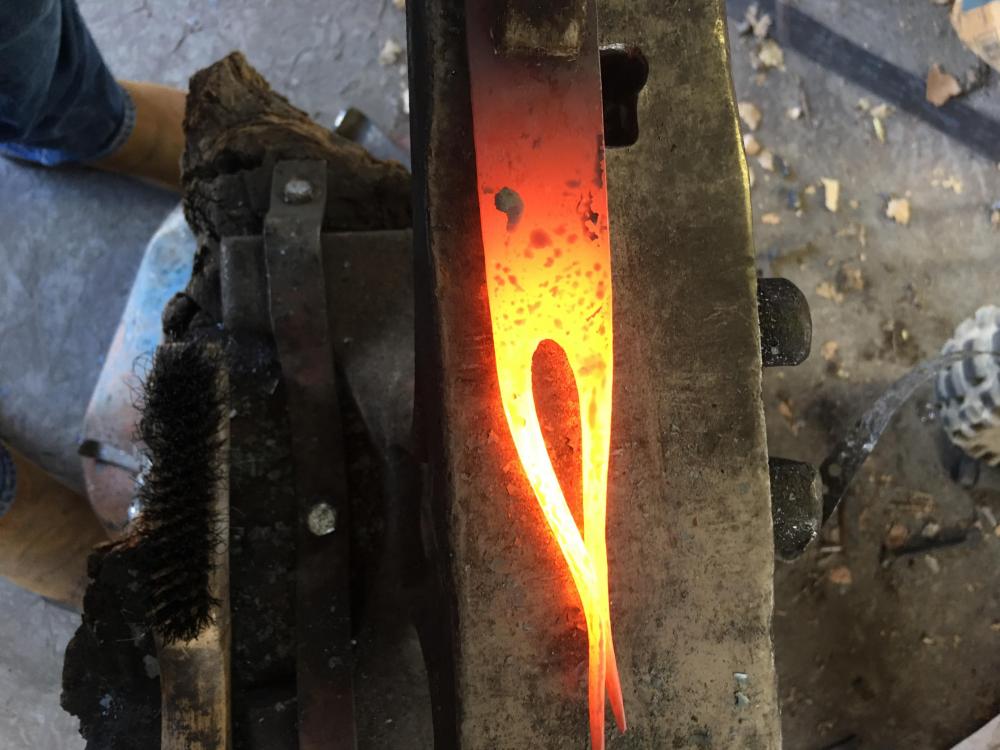

Made this cork screw out of a railroad spike. I used Mark Aspery’s pass through technique. This is my first go and it’s pretty rough. I will definitely be making more.

-

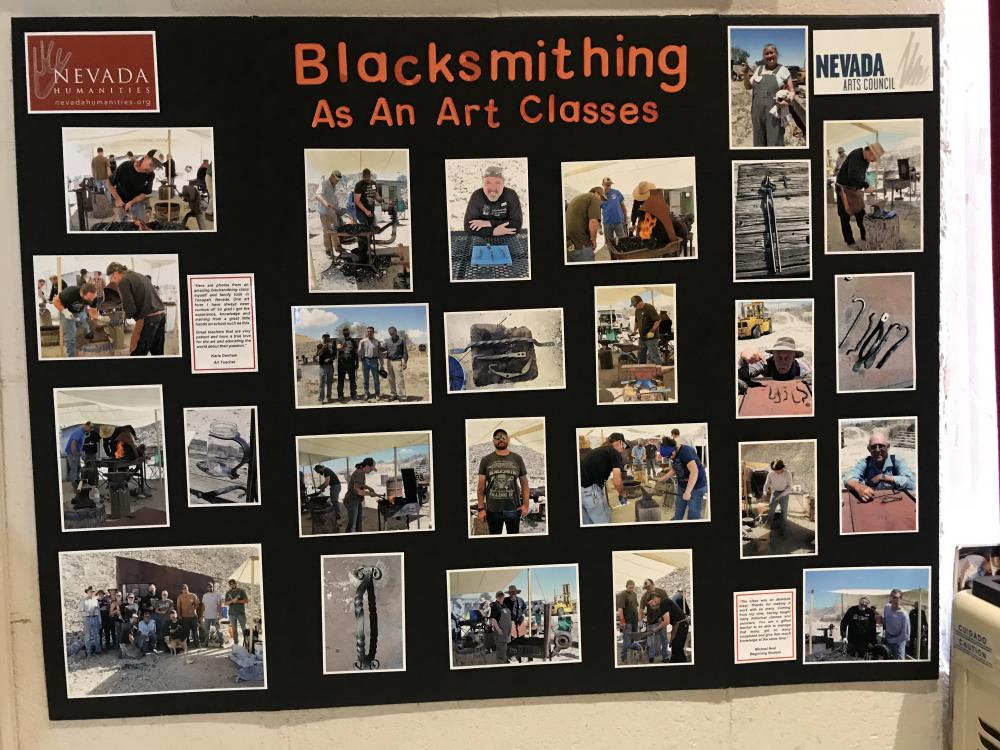

I’m glad to finally see this. I recently have been doing demonstrations and helping teach beginner classes at the Historical Tonopah Mining park.

-

Show me your Bottle Openers!

BlasterJoe replied to Arbalist's topic in Blacksmithing, General Discussion

-

An axe and herb chopper

BlasterJoe replied to BeaverNZ's topic in Axes, Hatchets, Hawks, Choppers, etc

Great pieces! nice Job -

Thanks Flatliner, I took it out in the mountains the other day and chopped some fire wood. then gave it to the boys and let them put it through its paces. Did some throwing and ice chopping. it did well still holding the edge well.

-

Thanks Thomas. This has quickly became my favorite tool. The same effect can be done with a striker and top and bottom fullers but this is much easier for a single man operation as my self. I have used it to draw out quills on feathers and even collapse pipe down for peppers and candle holders with lighter taps. Thomas, can you please show me your swing arm fuller or send me the link if you already put it out. It sounds interesting.

-

Yup. Fullered the quill out and used a cross pien for the texture. I have a railroad spike tomahawk I made along time ago that I use to chop in the edge splits.

-

Just finished the order for all 22. The client was very happy. I learned a lot through the process. By the end I was working 3 at once and got my time down to a half hour apiece. I didn’t make any money on it but it is for a good cause and good exposure. Forgot to pictures. The last one is my first one and last one. Big difference

-

Show me your blacksmith pets

BlasterJoe replied to Glenn's topic in Blacksmithing, General Discussion

This is little Bea. She’s 1 year yellow lab. She’s like my daughters. Comes in to watch me work and falls asleep. I must be a pretty rhythmic hammerer. -

Thanks for the great input. These will be for both demonstrations and for gaining interest for buyers. Thanks again and I will post some more pics from the demos and fair

-

I made my first rounding hammer. I made it from a worn out loader bucket pin. 4140. Water quenched faces. No cracks. Drew the temper with the drift I made. Feels really good to finally get it done. It’s always been my real blacksmith project. Need a tool/make a tool.

-

Frosty. First picture was first day second was second. It’s healing up well. It’s peeling like a tattoo. Did a little burn gel first day then neosporin. As to the way it happened I was making a spring fuller. I had the piece that goes in the hardie forged in and needed the large hoop on the back. Both ends were cold and the middle was hot. I was bending the hoop around the horn of my anvil. For some reason I squatted down in front while holding onto the cold ends and started bending. It cooled quickly and I thought I could get that last little bit done before reheat. (Always the wrong thing). I forced the bend and it popped off the taper of the anvil and I saw it coming, through my head back and it got me. The pictures look different because I had to shave that night to get the smell of burned hair off my face. It sucked shaving.