-

Posts

450 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by TwistedCustoms

-

Steve the amount of "poison" released into the air from burning the chrome off a hand full of wrenches is miniscule compared to the poison produced by operating a lawn mower for half an hour. If you spent as much time at the forge as you spend being critical of others just imagine what you could accomplish! I know you posses some knowledge that others can benefit from but taking a simple issue and expanding it beyond the realm of reason does no one any good. If we didn't want to poison our neighbors in any measurable way we would't be burning any fossil fuel, including coal.

-

New Forge Build and First Fire

TwistedCustoms replied to TwistedCustoms's topic in Solid Fuel Forges

I used to have the same deal with my steel supplier but they are now under contract with a recycling plant and won't sell "shorts" to the general public. Sad. I never need a large enough quantity of anything to justify a road trip. Now I'm stuck buying 20' even if I only need 6' but the upside is my reserve pile will grow. -

New Forge Build and First Fire

TwistedCustoms replied to TwistedCustoms's topic in Solid Fuel Forges

@arkie I live in a rural area, Central Mississippi and farmers are a good source! Forging metal has never been hard to find, it's usually the need for structural steel that sends me to the mill. I have a friend who owns a garage that does all the work for one of our cities police dept. They get new suspension on squad cars yearly so I have a mountain of coil springs and shocks. The shafts from the shocks are 4140 ish? Whatever they actually are they are water hardening and the springs are 5160 ish. I get lots of tractor discs too but most anyone with angle or c-channel etc hangs onto it for their own future projects. -

New Forge Build and First Fire

TwistedCustoms replied to TwistedCustoms's topic in Solid Fuel Forges

I don't have a "good" scrap yard in my area. The one closest to me is usually way over priced and several others I've been to no longer sell to the public due to contracts with recycling plants. The steel plant no longer sells tail ends for the same reason but they do have good prices even on small orders. I like having a variety of stuff on hand so I don't mind having leftover steel. -

If you're forging outside point a shop fan at your forge and stay upwind, the chrome will burn off of a wrench in a few seconds. My smithy has always been open air, a 20' lean-to on the side of my woodworking shop. I have a big fan hanging up that blows over the forge in the summer. An indoor forge or gas forge may not be a good idea but I've forged lots of wrenches into do-dads with no problems.

-

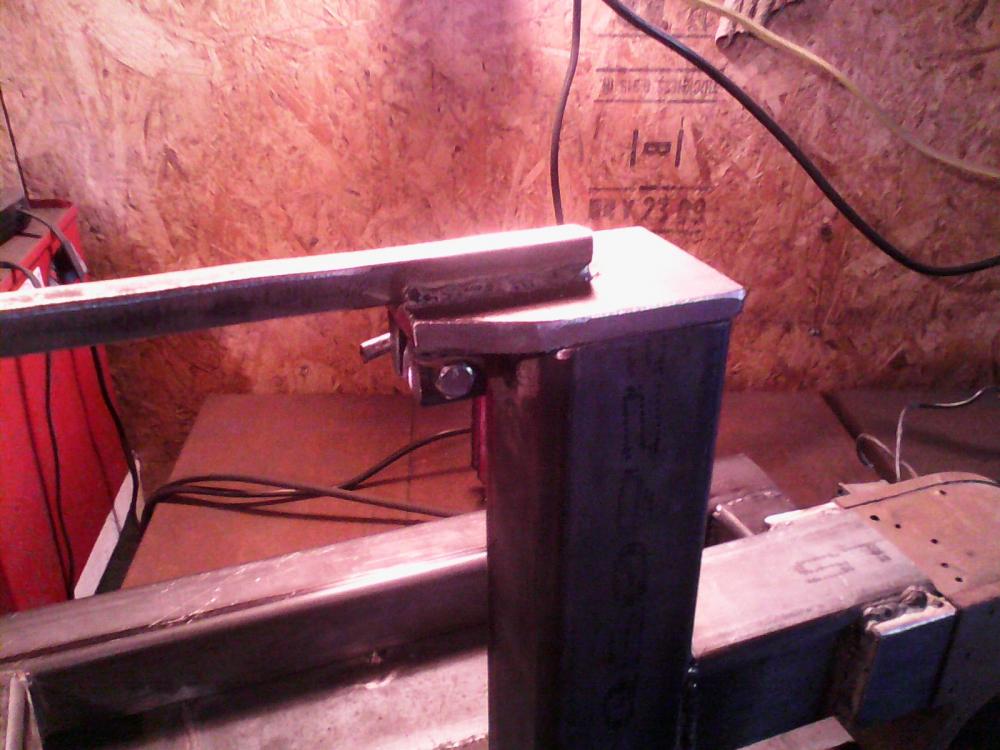

After three years of forging in a break drum I decided to upgrade my shop. Prices have gone way up on forges and I like a project so.... My local steel mill only sells 20' lengths of each dimension they produce so my material selection was done on the fly in the sales office. I wanted 2.5" square with 3/16" wall thickness for the duct. I never would have used tubing that heavy for the frame or legs but I had to buy 20'. I wanted 3/8" x 6" for the fire pot, not something I would have selected for the top but again, I had to get 20'. The end result is a quite sturdy little forge which has all the features I've wished for over the years of break drum forging. I took the fan from my old setup and added a dimmer switch for air control. The fan was a five dollar flea market find which refuses to die so it went into the new build. I made a clinker breaker, something I've never had at my home shop. I'm happy to say that it worked well on my first fire this evening. I also built a gravity controlled flapper for the ash dump, no more bending over to unscrew a cap.....priceless. Tomorrow I'll make tong holders to hang on the sides but other than that I think I'm done. Sometimes it's hard for me to know when I'm at the end of a project but I'm happy with the way it turned out. All in this setup ran $200.00 USD counting the welding wire.

-

my first coal forge build-lots of pics

TwistedCustoms replied to Teachagmech's topic in Solid Fuel Forges

Osage is a hardwood, aka bodock, aka horse apple. -

Adjustable torch holding tree for modular table systems

TwistedCustoms replied to 7A749's topic in Tools, general discussion

I'll take all those unwanted tools that are in your way ;-) Very cool design on the torch holder. I'm digging the modular concept too. As soon as bolt or weld anything down I need to move it. I feel a new project coming on. -

my first coal forge build-lots of pics

TwistedCustoms replied to Teachagmech's topic in Solid Fuel Forges

The clinker breaker won't see any action with the floor plates but I like your idea about raising the floor. Maybe weld a short duct extension to the bottom of a plate sized to drop in and rest at 2.5-3". Your pot is good as is without any floor plate, it's just a little deeper than it has to be for coal or coke. Forge with it as is and see if you like it, you can always try the drop in floors later. Nice knife, is that osage? -

I'll see your turret lathe and raise you a machining center.

-

As much as I hate to admit it Harbor Freight has everyone beat on abrasives. I've paid five bucks each for cut off wheels and five bucks for five-packs at HF and the cheap ones cut just as good. Also get all my flap wheels, grinding wheels, wire wheels etc there. They are consumable so why pay more for the same thing.

-

my first coal forge build-lots of pics

TwistedCustoms replied to Teachagmech's topic in Solid Fuel Forges

It may just be the perspective in the photos but the pot looks really deep. Four inches will give you a big fuel mass for sure. Unless you're going to be forging three inch stock daily you could get away with trimming it down and save some on fuel. Great job on the fab work, I look forward to seeing it finished. -

I was thinking auto body hammer from the T model era but crate hammer makes more sense with the pry bar end. If it is for hot work maybe some sort of farriers tool.....someone here is bound to have seen one like it.

-

Nice work! What did you etch with? Ferric chloride always makes my cable look wavy and never with such pronounced contrast. I like it.

-

Nice looking Nesmuk! Good job, keep the pictures coming.

-

FYI, I have found that most folks who are new to blacksmithing have no real understanding of anvil size as it relates to anvil weight. I make around 90% of my annual income on a 120 lb anvil and almost everyone who sees it for the first time guesses that it must weigh around 250 lbs. Just sayin ...... At any rate, as stated above, for a beginning smith an 80-90 lb anvil will handle many, many more projects than the beginning smith can handle and can usually be found for $300.00 USD or less.

-

Good vise, great price! Enjoy.

-

Very cool little rig, might have been used on a jobsite, rivet makers setup maybe?

-

When I was very young I worked for a finance company repoing house trailers. I went to pick one up that had been vacant for months. Up to that time I had never picked one up that still had the power or water on so I wasn't in a habit of checking. One of the chores of repoing trailers is to cut the condenser unit loose and throw it in the back door. This was the early 1980s and we didn't recover coolant back then, just cut the copper lines and power with side cutters and when all the freon shot out pick up the unit and set it inside. Anyway, the meter was gone but someone had stuck jumper wires into the base to steal electricity. When I cut the line going to the condenser unit I was instantly blinded by the flash and got a good coppery taste of ozone. My Klein side cutters were welded shut, not a1000 volt insulated pair, just regular Klein's. I never felt even the slightest tickle. I didn't ground out, no burns, no voltage, just a lesson I'll never forget. Oh, and also first hand knowledge that good old fashion tool steel is PLENTY conductive!

-

The handheld tools are probably the cause. If you're using a 4x24 or 3x19 hand held sander try flipping it upside down and mounting the forward hand grip in a vise. Then you can lock the trigger in the run position and have both hands free to hold the work on the belt. Of course that type sander wasn't designed to be used that way, you will eventually get metal dust in the motor and shorten the life but in a pinch.... Anyway, investing in a belt grinder designed with knife makers in mind will move your work ahead faster than improvising and jury rigging. You can always make a file jig and hand file the bevels too. Scandi, flat grinds are quick and easy with a bevel block but that requires having a tool rest mounted 90 degrees to the platten. It would be tricky to set up that type work rest on a hand held sander but it could be done.

-

Thinking 'out loud'/Self defense for the ladies

TwistedCustoms replied to Michael Cochran's topic in Knife Making

It's already been stated here but I'll add my 2 cents because I get asked this question from time to time. The idea of anyone, man or woman, who has little or no training mixing it up with a knife and expecting a happy outcome is rubbish. There are about ten thousand other things that can be done to avoid being targeted in the first place. If it is in fact prudent to carry a defensive weapon then based on your location a handgun should be an option. I don't know about Al but in Ms women don't even need a permit to carry in a purse or hand bag and if they want to concealed carry in a holster it's as simple as getting the permit. The sight of a gun in anyone's hands will give a bad guy more to think about than the sight of a knife and the booming sound a pistol makes has been known to make burglers run the other way without drawing blood. I know this is a world wide site and not everyone reading this has the option of carrying a gun but "when in Rome". -

Wonder no more....I worked in manufacturing and I know it's possible for a production facility to have a bad run but sheesh! A lot of old name tool companies have been bought out and while we still see their logos on the shelf the products are only a shadow of what they once were. I don't hate China, I hate poorly made junk that tries to pass itself off as premium. What I have seen time and again when companies move manufacturing to China as that the early production runs are spot on. Then, as soon as the over site of the US setup team is gone the factories start cutting corners and if left unchecked the quality drops off the chart. Sorry for the rant, yeah it was HD.

-

My background is in manufacturing. I worked for several valve companies that supported the offshore drilling industry before deciding I would rather be happy than successful. These days I forge, fish, do a little trapping, tie fishing nets, read (nonfiction) ,do some primitive woodwork, and spend time with my animals. My only vices are smoking one of my old Dunhill pipes and drinking the occasional cream soda. I volunteer at a living history museum and hang out with other local smiths.

-

I second the Black Diamond but be aware that the Nicholson logo is still in use but it is now stamped on China junk. Black Diamonds are a safe bet, old Nicholson also but the operative word is old. If they are high carbon they should be close to R64 if they haven't been through a fire. It shouldn't take more than a tap with a hammer to snap an inch off of a good file when it's locked in the vise.I picked up a large Nicholson mill bastard at a big-box store and was able to put a right angle bend in it in the vise without it breaking. The outer skin peeled close to the bend, looked like about .050 deep case hardening.