Teachagmech

Members-

Posts

25 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Central California

-

Interests

Welding, fabricating, fishing, hunting, and raising my kids of course

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

The one thing that’s obviously a wild card to me is your elevation. I’d be tempted to build a blown forge with a ribbon style burner if I lived that high up. That being said, I think you can still make a working forge, welding temps just might be really hard to reach. Like frosty said, change only one thing at a time and take notes. The first thing I would try is opening the door/taking it off. Then observe the difference in flame character from where it was in the last pics. Go from there. You’re probably still going to want to seal up around the burner tubes.

-

Does your forge have a way for gasses to get out? It looks sealed. You have to think of the whole thing like a tunnel not a tank. If you don’t have flow through the whole system, you’ll never draw in enough air to make it work correctly. I would seal up the gaps around the burner tubes as the jet of flames is consuming oxygen from around the air intake of the burners. when I want to hold in more heat, I set a brick in front to reflect the heat back, but still let’s the exhaust out. Using a refractory kiln wash also helps a lot with heat retention

-

Alright. I put together my stacked brick forge. Mounted the burners, cut two new mig tips to half the diameter of the tee for an air gap and fired it off. It's actually not too bad. Depending on if I have both ends open or not it will occasionally fall out of tune where the flame goes out and the gas is ignighted my the other burner. It's pretty hard to get a picture of that though so I put a video on youtube

-

I'll take some pics today when I get to work. We're on a pretty tight budget, so I don't have the kaowool and castable or the IR reflective coating to finish my "good" forge yet. I bought some hard bricks yesterday to make a little bench too cubby forge to make some stuff to hopefully sell at a craft fair coming up next month. I know they won't be as efficient, and the burners likely won't act te same as in the 20lb propane cylinder forge, but I'm just hoping to get a hang on how they're supposed to work. Buzzkill made a good point that I was overlooking: back pressure from the forge. I'll get an update and post back later today

-

Out. Forge isn't built yet.

-

Anywhere from 4-25. Nothing would stabilize unless I choked it. Choked it was very stable through the whole range, but it lacked "fury" if that means anything. I currently have 1" with 3/4" chase on them. I picked up the 3/4 on my way home. I won't get back to it until tomorrow.

-

I'm going to drag up this dead thread to seek advice on my build. I am making 2 3/4" T burners. I built them directly off the plans, using tweco .035 mig tips. The only difference between what I have and the directions is the 1/8mipX1/4 flare adapters that were available were 90* elbows. I used a milling machine to drill the holes in the tees. Indicated a piece of pipe to center, threaded the tee on, drilled, and tapped before moving anything. The jets point directly down the middle of the burner tube. I forged out merchant couplers(thread protectors) to mimic the rough 1:12 taper for the flare nozzles. The problem I'm having is getting the flame to sustain off the end of the nozzle. I have to choke one side completly off and almost 20% of the other side to get it to stabilize. It seems like the gas orifice needs to be further into the burner tube. I tried trimming it down (in vain) thinking it needed more space to mix and more air. I trimmed it all the way down to about 3/8" from the face of the brass fitting. after fiddling with that for quite some time(including trying .030 and .045 mig tips since I had them) I finally pulled the gas apparatus out of the burner, pulled the tee off the end and held it in place in the burner tube while a few assistants helped with lighting and manning the gas valve. I was able to get a much bluer, louder flame. I'm at a loss. I bought some 3/4" tees hoping to get the mig too closer into the burner tube, but I'm not sure if they will work. I know YouTube is not a reliable source of info, but my flames do. It resemble those of other t burners I've seen. My flames look green. If I add more air(or choke less) the flames go out. Thanks!

-

what did you make the stand out of? sure looks pretty! I'm in the market for a new anvil for work

-

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

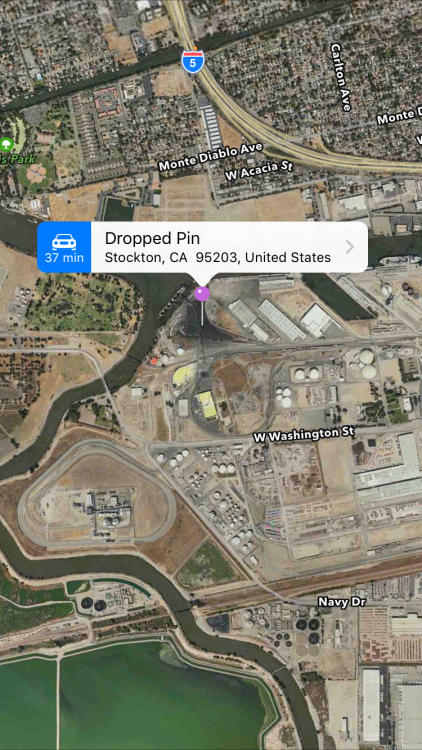

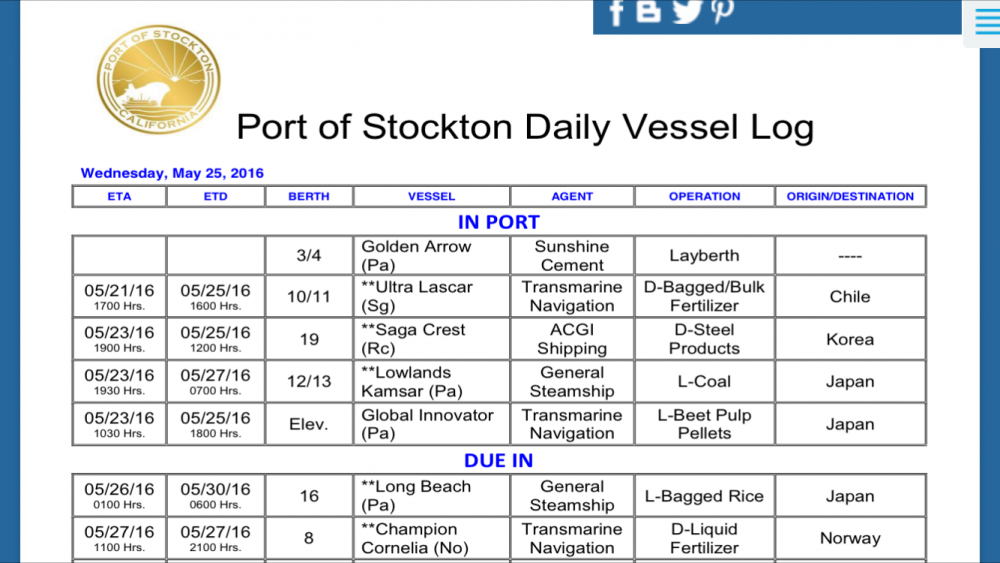

Well I called the port today to try to play the teacher card. I'd really like to bring forge work back to the high school shop. From my house, it 30 min to the yard in the port. I doubt they'd miss even 200lbs in a 55gal drum. -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

I know there used to be a coal seam about 50 miles from here, but it's all since been shut down by green do-gooders from San Francisco and Los Angeles. 30 years ago it'd be easy to get. And if liberating a few pounds off a railcar wasn't a felony I'd have a ton by now. There's a siding across the street from me that frequently overnights coal trains headed for the ports. Too bad they don't sell to the public. -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

It seems like as soon as the fire fleas stop biting the charcoals gone. Around here my worry is set in the countryside on fire. The $25 a bag for Coalsounds like it's hard to be worth it too. Heck buy it from Centaur Forge for $50 a bag doesn't sound that bad for what I paid for the charcoal -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

Alright, so it works! but man does it ever make a friggin mess! The ash fireflies are a real b&*[#! And they don't feel really good when they fall on your arms end of the hour I've decided I definitely need to cut the firepot down. It's way too deep. I can only get to about 5-6" of material in the heart of the fire. I really wish I had a bag of coal or coke to use. I went through 20lbs of charcoal in about 90 minutes. I also want to put a smaller fan on it. The blower is WAY too much air. As I thought. -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

I've tried. I saw the thread, checked it out. No dice here. They can't even order it. Which kinda pizzed me off a bit since TSC is literally 12 miles from my house. Loomis is a solid 2 hours. Maybe I'll get a friend who's going to Colorado for deer season this year pick me up a couple 4-5 bags on his way home. I'm not super happy with my forge table right now. My last band saw blade bit the dust at work the other day, so building a real table isn't in the cards this school year. I've got it tacked to a makeshift repurposed table thing I pulled from the scrap bin. It's pretty bad and a tad short, but it'll work for now until I figure out how to swing a hammer. Well give 'er 'ell in the mornin tho -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

I picked myself up a 20lb bag of mesquite lump charcoal for $12 today. I found a place to buy coal and coke for $25/50lb bag. It's about as good as I can find. If I ever get up by Loomis, CA I'll stop in and get a bag. I think the consumption of coal/coke would be less than that of charcoal and it's the same price. I also like that coal doesn't send off fireflies like charcoal does. Any my input would be helpful. If i like th charcoal and there's not much benefit to coal over charcoal, then I'll build a retort and make my own. -

my first coal forge build-lots of pics

Teachagmech replied to Teachagmech's topic in Solid Fuel Forges

I've used the oxy fuel method a lot at school, but it's a pricy heat source to say the least.