-

Posts

830 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Crazy Ivan

-

Un identified object

Crazy Ivan replied to Arceye Blue's topic in Tools, ID, and pictorial reference

What does pulling the lever do? If it's a snappy.little hammer contraption, then it may be a saw tooth blade setter tool. -

Is a $140 hammer really that much better than a $40 hammer?

Crazy Ivan replied to Pancho07's topic in Hand Hammers

This proves the point right here. The blower handle you have might work fine, but I does not match up to a fine, custom, handcrafted tool. -

There were 3 forges for sale at the last one. When I left, none of them had sold so you may be able to get one this time. Iirc there was also a couple post vises too. All reasonably priced. Like I said before. Bring some extra $$$

-

Is a $140 hammer really that much better than a $40 hammer?

Crazy Ivan replied to Pancho07's topic in Hand Hammers

It's more an appreciation of quality tools and honest work. I would be much more proud of a hand forged hammer, custom made to what my needs are. Does a 3 lb hammer from HF move metal better than any other 3 lber of the same geometry? No. It's the user who makes the tool earn it's keep. Even still, I would rather use a tool that was made with care and skill vs mass produced but I may be biased...I make hammers. Lol. I do not claim my hammers are going to make you better, but I I claim they will be more comfortable to use AND last way longer than a cheap hammer. I can also tell you exactly which alloy I use,how I heat treat and why. Myself and most(not all) hammer makers use alloys that are better (more expensive too), and more fit for a heavy use hammer than say the more common 1045-1050 range. Though over time, comfort becomes what you are used to. Even though I make any hammer I need or want I still want to buy one of Aaron Cergols $400 hammers because I thoroughly enjoy and appreciate craftsmanship and personal artistic direction in a hand forged tool. Not because I couldn't make the same hammer, I just want HIS hammer. Which brings me back to appreciating a quality tool made by a fellow Smith. My 2¢ -

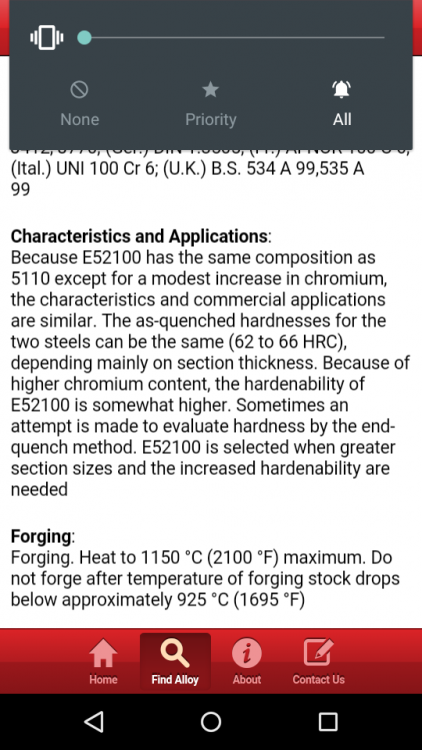

Lol. Here's the spec sheets on 52100 for you. Using the heat treaters guide app. It's awesome for working with new alloys and even better.... It's FREE!

-

4130 is used for stage combat weapons since it can be heat treated and tempered to a strong resilient and flexible item. It will not hold an effective edge however. It is used as a stage combat prop unsharpened and is used because if treated properly, will not shatter and hurt the spectators/actors. Are you making props, wall hangers, or actual swords meant for use? The answer to that will dictate the materials you need to use to get real quality results.

-

Steve got it. Last month there were some great books, some awesome large top tool swages, misc medium carbon steel and other useful items.

-

The most important detail is that the meeting is on the 2nd, not the 4th. Yes you can still go if you are not a member. Bring something for iron in the hat, a camera if you have one and a pen and paper to take notes during the demos. Unfortunately I can't make it to this one since I accidentally booked a full class on that same day lol. BRing some extra spending money too. There is tailgating and raffles.

-

steel Help To Identify Steel Please

Crazy Ivan replied to Depuuty's topic in Blacksmithing, General Discussion

Why don't you ask him who the suplier is and ask them for a spec sheet on it? Cut out any guess work. -

Heat to critical then place it buried in vermiculite or wood ash. It's best to have a large hot bar of steel next to it to help it cool as slowly as possible. It should still be warm to the touch the next morning. Then it is annealed. Drill away.

-

When I make drifts and top tools and dies for struck tools or the power hammer using h13 I usually heat it slowly in the gas forge or set it on top of my coal fire until it has an even preheat, then forge the tool while the ENTIRE area and surrounding area to be forged is within the forging temps I noted earlier. I've yet to have any trouble with it other than how it doesn't like to move under the hammer. After forging I let it cool down in the forge as it cools. Then I grind, bring back up to heat and let it sit in STILL air. Then I use it. This is what works for what I commonly make. Ive had no problems to date. Depending on the materials area, things change. Thinner sections and thicker sections require slighly different treatment. Look up the heat treaters guide app. It's free and has all the info you may want.

-

Have you looked at the minimum and maximum forging temps for H13? 1950-1650 is the start and stop temps for forging. If you are staying in that range you shouldn't have issues with heat checking.

-

Thank you. I just had some photographic hindsight where I realized I definitely need to make a 2nd fullering tool to make the "twists" run opposite on the opposing side of the hammer. That way they accent eachother better. I think that may look even more slick.

-

Lol well that's exactly what I got on my 1st attempt. Not every time, but almost every time I tell myself "I've made so many of these, I know it's right" I make the wrong one lol. That's fine though since there's more rightys out there and I have a very nice 2.5 lb right hander on the bench waiting to be handled. I promised Nick that same hammer so it's a win win. Been too busy to finish up my give away hammers lately. Soon though.

-

Finished up a fun order today. 3 lb left handed diagonal cross pein, 2.5 lb rounder and a heavy 3" flatter. American hickory handles burnt and finished with blacksmith juice (BLO, turpentine and beeswax). 4140 for the rounder and the flatter and 4150 for the diagonal.

-

Another great display piece. Nice work Aric. You definitely capture motion well. I 2nd you getting that tig welder out more often though . I can always tell your posts by the titles before i see your name under it lol.

- 35 replies

-

- rabbit

- run rabbit

-

(and 1 more)

Tagged with:

-

Making a flatter is alot of work. I use 2" stock and draw a taper from 1.5" to 1" at the struck end with the face being 2.5-3". Even easier and in some cases, better, is a set hammer (used like a flatter but made to isolate transitions) where all you need to do is punch an eye and taper the struck end. I use my set hammer in hammer making often. Flatters, not so much. They have their place but the face extending beyong the shank is not good for defining a corner as a set hammer is. I use 4150 for mine. Make it the size and style that will fit YOUR needs.

-

Flames go up, not down. As long as you don't have leaks in your feul line it will be fine.

-

It came out great too! Perfect for when you have steak for lunch but no time to get away from the forge to cook. Definitely an "inbetween heats type of meal" lol. I took video of the 1 minute it took to cook. I'm having trouble uploading it though. I'll try again later.

-

Much more control with it. No need to do the balancing act for softer blows. We were split between a wooden frame around the base of the hammer (for a heel rest) or a pedal. The pedal is great though. Idk why I don't see it on more hammers.

-

I like Knives just as much as the next guy but I'm not one to get excited over one. This is the exception. Great work! The coin on the sheath is a really nice touch and that guard is just plain awesome!

-

US Navy SEAL Trident

Crazy Ivan replied to basher's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

That looks amazing right down to the joinery. Did you use Damascus for your rivets as well? -

I thrive under curmudgeonly banter.

-

12"x12"x1"=40lbs (sq ft) each sq ft by 1/8" incriments of thickness=5 lbs Cubic foot = 12" x12" x12"=480 lbs