-

Posts

3,246 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by anvil

-

So, the simple response is apparently you disagree with using common words of these crafts, but i know you cant mean that. And, no, there are commonly used terms for both the farrier and the blacksmith. I asked you in a previous post to explain what "pulling a shoe" means as I had never heard that term before. I got no answer, and still aren't sure of your meaning. I've pulled clips but I've never pulled a shoe. I've rolled toes,bent/turned/shaped,rounded a shoe,made a heel calk, etc and most farriers I've come across understand these terms. As far as blacksmithing, I've never come across anyone who doesn't understand "drawing out", so I'd guess that the term "smoosh" must come from a pretty small region.

-

Absolutely critical.

-

Jen, take a couple wraps. Its cheap, quick, and easily replaced and easily found, I mean, everybody knows "duck Tape". . But hey, the point is, you can use a good heavy duty tape of most any kind to tighten up the fit of a loose hardy. If the "windage" is too much, there are other ways. Again the important thing is a good snug fit, correct? And often times, beats making a new one.

-

What Thomas said, H-13 is best for hot work. Check out chasing and repousse tools for ideas. With a few tools, again like Thomas said, you can do a lot with the proper tools. Teeth, tongues, scales, ears, on and on. Basically you can sculpt anything you can think of.

-

You can buy new black(non coated) nuts etc at Fastenall

-

Ive never used a chisel to true up a hardy hole, but it cant hurt. Ive filed a few. Thats my preferred way. You have the best control with a file. \

-

Type of steel for geologist tools (hammer and chisel)

anvil replied to Chrigneous's topic in Hand Hammers

As a hand forged project, this is a very complex forging. A one piece hammer/handle combo is better done with an industrial setup. Heat treating will also be rather complex. You will need to ht both ends as well as the transition from hammer to handle. Not that it can't be done in a one man shop. Keep us informed. -

I never use just linseed oil. I mix 50/50 linseed oil and turps. Then add a walnut sized piece of beeswax to the mix. This is for a pint of each. I've never had a problem with this mix on any household iron. The caution is to make sure that after you apply the finish that you clean it well with denatured alcohol. Black smuggie on your towels will not win any smiles.

-

Heres my rule. A hammer should be softer than the anvil. The difference can be small. A struck tool should be softer than the hammer. The difference can be small. Never strike two hardened objects together unless you know for a fact that one is softer than another. The difference can be small. I've heard the box store deal before, that the have decreased the softness for insurance reasons. However I've never seen anything to validate this. But it doesn't matter. I'm pretty sure that mass heat treating is the commercial way ht is done. Meaning hammers are not tempered one at a time, but many at a time. What I dont know is are 16# sledges tempered the same as a 2-1/2# machinist hammer for any mass outlet, much less box stores? If both 16# sledges and 2-+/2# hand hammers are mass tempered the same, then there is my problem. I'm not really a safety nut. I have no problem with how people choose to be. Education as to potential problems is important, and the only reason for this post.

-

Charles, there are two ways chipping can happen. If you pull a straw temp on a knife and use it as a hammer, it may chip. Wrong temper for the job. The other way is if two hammers have the same temper. If these strike each other, you may get a flying chip. So my shop practice is to not strike hammer on hammer, unless you have retempered the one to be softer relative to the other. On the other hand I always temper the struck end of my hand tools. But I always temper them far below that of any hammer. This means no chipping, and the end takes longer to mushroom than if its annealed or normalized. Hope this makes sense.

-

What did you do in the shop today?

anvil replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr, Absolutely Beautiful! -

Absolutely correct. The key word being "supposed". Accidents rarely happen when you do things that you are supposed to do. Rather more common with new guys, than those with experience. And when good advice often given is buy your hammer at yard sales and flea markets, who knows what ya got. Safety be what safety is.

-

Without a doubt, its more "I found it on the internet" without an internet footnote.

-

How to forge a flatter.. No swage block used..

anvil replied to jlpservicesinc's topic in Tools, general discussion

Sorry for any misunderstanding. I was not disputing anyone. I presented a different way of solving the problem, Jen replied and presented possible problems, which is appropriate for anyone to do. I answered her critiques. I indicated I did not understand something she said and, i still dont understand what she meant. Jen, to answer your question, the end of the bar is not important, three of us now have presented ways of dealing with the problem. That's recentering the upset with the parent stock. Another way of solving this problem, if your parent stock is long enought to hold in your hand,, dont use a hammer at all, just bring the stock down hard on your anvil with the upset hanging over the far edge,, one sharp rap, and the problem is solved. Any other solutions? Alas, we are learning just why an upset can be an upsetting experience. And, most importantly, showed a use for a rounding hammer that many have never considered. Isn't that why we are here? Answer questions, Present our knowledge, give solutions to critiques, and give choices to others in order to increase their skills? So, Jen, when I show a different solution, it's no critique on you, its just another solution. Please dont take offense. -

Just the reason I dont recommend using sledge hammers as an anvil unless you either use a softer hand hammer, or draw the temper on the sledge to a softer state.

-

How to forge a flatter.. No swage block used..

anvil replied to jlpservicesinc's topic in Tools, general discussion

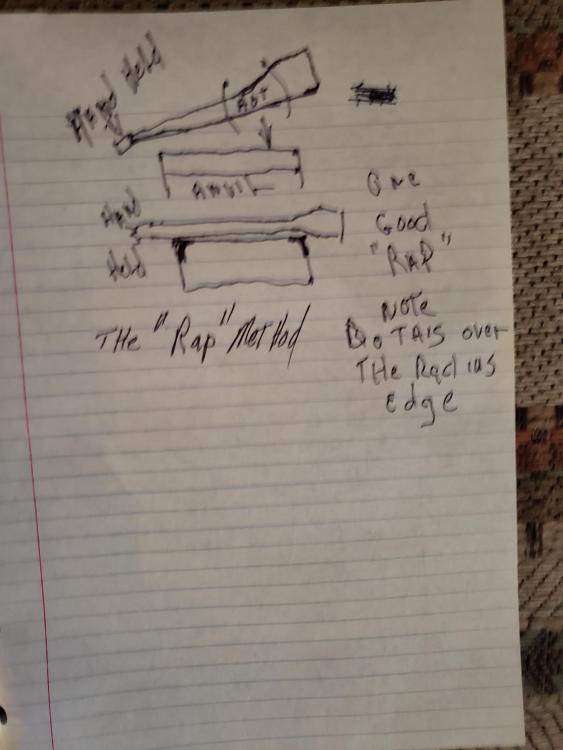

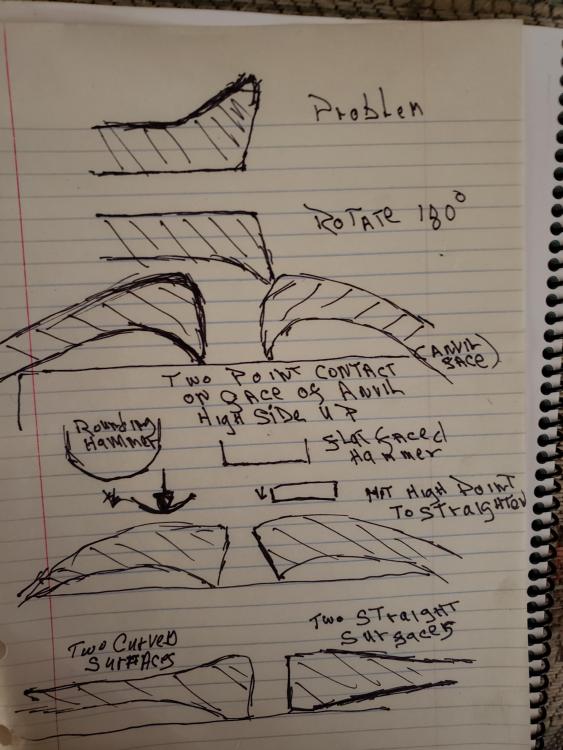

Sorry I took so long to respond. I wanted to do a vid, but mother nature intervened. I've got 3' of snow over my tools and the carport is now the mechanics shop. So a pic will have to work. Actually, what i said has nothing to do with rounding a shoe, it is just applying a rounding hammer , not a ball peen or a flat faced hamme , to straighten on the face of the anvil. Thats a 2 point contact and high side up. Then use vertical blows to straighten. Pretty straight forward. The farrier technique you are talking of is a 2 point contact on the horn, and strike the iron beyond where it contacts the anvil. Thus turning or bending the shoe. And I have no idea what you mean by "pulling the shoe". Again we have talked before of "pushing iron". I don't "push iron", i forge it or I bend it, and generally with blows that are in the vertical. Just this alone as a general rule, will keep your body safe. Again, I have a 2 point contact on the face of my anvil, high side up. Thus no problem of improper pressure anywhere. I know you are sensitive to this. Seems you have said you were down for 2-3 years after quitting your hardware business back in your early 20's and couldn't raise your arm over your head!. As for a cold shut, nope, that wont happen for 2 reasons. first, my anvil edges have a radius about 3/8" to 0" from the step to about where the heel begins, and second, get it hot where you want to bend it and don't get it hot where it might get dinged. This is called heat control, for those who aren't aware. As to distorting the large end, in this case, its not a problem as it will get more upsetting after correction. thus thats not an issue. No critique, different technique. And a technique that most, even experienced smiths, are not aware of. That is using a rounding hammer for its named purpose,,, to Round either convex or concave. So, Jen, in truth I had two reasons for this post. The first was to show the OP another technique to get to the same end as your example, oranges and grapefruit. The second was to introduce a technique that i feel many smiths are aware of. And that was to show a solution to a problem using a rounding hammer for the very reason was named,,,, wait for it,,, a rounding hammer creating a "round". Lol, oranges to grapefruit,,, yup,, personally I'd like to see a few tangerines and limes added. Maybe a tomato,,, -

Lol, one tweet deserves another!

-

What did you do in the shop today?

anvil replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice! -

Nice job!

-

I wouldn't heat treat as was mentioned in the OP "on a lark", you might say.

-

"Macbruce" here on IFI did a good series on flame straightening heavy plate.

-

Me too. Heres my thoughts on a major difference between then and now. I think of the "golden days as a time of limited types of steel, and max knowledge on breaking down temper color spectrums to achieve proper tools for differing situations. One kind of tool steel,,, carbon steel. So I call this time "The Age of Carbon Steel". Carbon content was relativity easily recognized by a spark test. And basically three types. Low, medium, high carbon. I believe in Richardson's "Practical Blacksmithing, I remember agricultural Smith's speaking of dozens of ways of hardening picks depending on the type of ground, from granite to loam. And now we live in the "Age of Designer Steels" Metaphorically speaking one might come up with a specific purpose, and go to "your local steel designing engineer" and he will design a specific type of steel best for that application. And, it works "best" when max hardened and "tempered" to a spec to give it max Rockwell hardness. Thus no need to take a color band and break it down to a dozen "shades of grey". And that answers my question above as to why there seems to be no data on varying tempers in modern steels. There's just no need to do that. However, one today can still take any type of steel and figure out varying situational tempers. But unless you are "just" a traditional Smith, it's rather redundant.

-

Common Basic Mistakes That Beginners Should Avoid

anvil replied to JHCC's topic in Blacksmithing, General Discussion

Another way is to dump your ash, leave your ash dump open a bit, and poke a hole with your poker thru the top of your coke. It only takes a small, clear opening top to bottom to allow air to pass thru to keep your fire alive. -

Etiquette when working in groups

anvil replied to Shabumi's topic in Blacksmithing, General Discussion

I never have more than two at a forge, and both always on the same side.