-

Posts

399 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Nevada City, Ca

Recent Profile Visitors

2,116 profile views

-

I hadn't thought of an audio cue for top tool work, that makes more sense than a visual one when the smiths hands are busy with tooling. It also makes sense not using the word "okay" as your GO word. I am one of those that says okay to sort of focus myself before doing something and would be in trouble if that were the signal to strike. Your right, I did mangle that phrasing. Thanks for the correction.

-

JHCC, it seems like Aislinns signals are similar to the ones described in the article, with a few minor changes to start, stop and change speed. They both basically say the little hammer mimics what the big hammer should do. It makes sense from an efficiency standpoint. The striker just has to keep his eyes on the work for instruction instead of looking to the Smith for direction and then back to the work. That would help with accuracy by not having to split your attention and also save a split second each stroke. That isn't a big deal if your only striking occasionally, but in production work those seconds add up. I also noticed that these signals seem to be about striking the piece directly with the sledge, and not about striking a top tool, which I think would be better with the head nod method as the Smith has to adjust the top tool between each strike

-

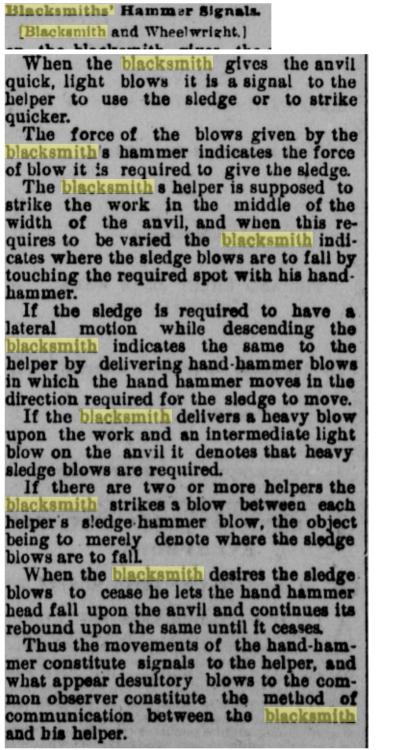

I found this article in the Jan 6, 1886 edition of the Truckee Republican about how a blacksmith would communicate to his strikers with different hand hammer blows between strikes. I appologize about the highlights, I wasn't sure how to remove my search keyword from the website I was using.

-

I managed to hike this beast a half mile out from an old (1930s) mine site on a buddies mining claim. When I told him I forged, he mentioned finding it with a metal detector, buried near the entrance to the mine, and said if I could carry it out I could have it. I can almost guarantee that the reason it was still there after all those years is the hassle it took to get it out. I haven't done any measurements yet, but I'd estimate it at 80-90lbs based on it being not quite as heavy as 2 bags of chicken feed. She's pretty pitted from rust on the faces, but some of the sides look decent.I like how the hex sides are split and have different sizes in each slot. Time to do a clean up with a wire wheel and see what's hiding. Might just be a conversation piece.

-

Pretty interesting picture. When you zoom in on the anvil it looks like the shelf that would stop it from sinking is wedged in the crotch of a sideways branch. You can also see the tip of a clay tuyere going into the fire from the right so the bag the guy on the right is holding is most likely the air supply, and I think he has a second air bladder that's empty in his other hand, double lung style as frosty suggested. Oh, and you can see (char)coal in the wide basket on the far left, maybe more in the basket in front of the center man. I also like looking at the background, I see a cook fire in the top left corner tended by women, and 2 or 3 other possible blacksmith groups behind the woman with a child and the guy lighting his smoke with a coal. All this is going on about a day's walk from the town that you can see in the far background. Possibly getting ready for some trading?

-

What did you do in the shop today?

Shabumi replied to Mark Ling's topic in Blacksmithing, General Discussion

His class was extremely informative. Some of the advice he gave that stuck with me without having to go through my notes that may help others is to outline your design when the piece is flat, with a very thin tracer with a hard backing, like wood, before raising the piece to the height you want. It should be a light enough line that it can be blended with your corners/height differences, but deep enough that it doesn't disappear when you are working. To work from the bottom-up, in terms of a 3d model that means to start at the lowest/deepest/furthest back level and work your way to the front/top. As you work each level, it will work harden and help support the next level up so it doesn't sink as far when you work that level. As long as you don't go too far, work hardening is just another tool to help you. Also on that note, he would only anneal when he absolutly has to, and only the small section that needs the annealing. You worked hard to get the structure and rigidity you've created and annealing the whole piece removes that, so he would spot anneal with a jewlers torch. The last advice I can remember off the top of my head is that pitch heat management is a big factor on how effective your blows will be, if you start out with warm pitch, the it will take a smaller blow to get the same result as a large blow with cooler pitch -

What did you do in the shop today?

Shabumi replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey everyone, it's been a while since I've been on and even longer since I've posted. Took me a while to get through the 150 pages of what yall've been doing and I have to say there is some mighty impressive work. It would be impossible to mention it all, but I will mention on a few. Alexander, your work is as amazing and beautiful, as always. Jlp, I always learn so much from your work, and it was great seeing that you got to work with some names I recognize. Dennis Dusek is a big part of the CBA and I've really enjoyed learning from him, and Beth Holmberg was part of it as well before she moved a few years ago, she taught one of the first classes I took. JHCC, your repousse work is looking great. I've been doing a bit of repousse myself and had the pleasure of taking a class taught by Douglas Pryor. We did a rose. If you haven't seen his repousse work, you should check it out. It is quite impressive. He brought an alligator to a spring conference that he raised/repoussed/chased from a 8 foot by 4 foot by 1/4 inch thick steel. It was almost lifelike. I included a picture, as well as a fee of the things I've done since last on here. -

I had the same problem. I can see if someone does a lot of repousse, that they might want to make a harder batch for summer and softer batch for winter.

-

Sorry for the late response, I haven't been on the site for a while. That is by volume. If you are planning on making some, I'd start with half the amount of BLO and see if you like the consistency. It's much easier to add more than it is to take it out.

-

Chicken problem

Shabumi replied to Jaegers Forge and Foundry's topic in Blacksmithing, General Discussion

We've had a juvenile coopers hawk hanging around our front yard the last few weeks. He's not afraid of us at all, I got 5 ft from him today. He's been munching on our finch, tit and starling population. We will hear a commotion in a bush next to us and out he pops with a bird in hand. I love having guinea fowl around. Watching a car stop to let them cross the road, only for a guinea to take offense that the car stopped and start screaming at it. Its even better when the person driving starts honking to get them to move. It becomes a battle of stubborn stupidity that the human usually wins. I remember some time ago a study that had ravens ahead of chimps when solving multi step problems. IIRC the chimps could consistently figure out 4 steps to conclusion while the ravens would consistently get 6 step conclusions. Something like push open a drawer with a big stick inside, that can be used to release a rope, which is pulled to get a little stick, that fits in a hole to press a button that opens a door with a treat. -

What did you do in the shop today?

Shabumi replied to Mark Ling's topic in Blacksmithing, General Discussion

That's what I was trying to go for, smooth. I was going to stay away from the step and cube twists. These still need a wire brushing, but there isn't anything that catches my shoulder length hair, the first time I've had hair this long since I started highschool 20 yeas ago. I'll make a few of smaller stock as well in case 1/4" is too large. It's hard to know what he wants when he doesn't know what he wants. Haha, it looks like we had the same problem with not having a long enough stem to wrap around itself after making the loop. Yours ended up with a better post than mine. The tip on mine just needs a quick lick on a belt sander and it could be considered a belt knife. Im just happy I got a fairly decent center ridge on my leaf after 6 months of downtime. -

What did you do in the shop today?

Shabumi replied to Mark Ling's topic in Blacksmithing, General Discussion

I actually managed to get the forge going before the new year. I'm out of practice, but my leather working friend asked me to make some hair pin samples for his leather hair holders. There are still others samples to be made, and he wasn't sure exactly what he wanted so I did/will do a couple different twists, lengths, handles and tip shapes so he can mix and match for the ballpark hes looking for. If he likes what he sees ill be getting $10 for each one someone orders, not bad for a 5"-6" piece of 1/4" round. Also tried my hand at a leaf belt buckle. I like the leaf part, but making it by eye when I'm out of practice wasn't the best plan. While fiddling to get it "right" I ended up making the stem too short, the eye too small and the tip too sharp to be used on a belt. I will end up making it into a bottle opener. I think a jig will be in order if I want to make it cleanly. -

More book size. The whole thing folded up is 12"x8.5". A buckle would be nice, it has a thin leather string to tie it closed. Twigg, thanks I'll pass on your compliment. That pry bar looks like a nice score. You would be surprised what you can bend with a long enough cheater bar and a "I WILL get it" attitude

-

Id love to try, but thats well above my pay grade(so far), it was just an amusing thought I had. I'll set this in my back pocket for when my skillset has caught up to my imagination. George, I've always found my natural gait to be ball first, and my heel hardly ever touches unless I'm standing still or in ski boots. I think it may come from stepping on too many banana slugs barefoot when I would sneek out of bed as a kid. If you hit them heel first you'd go sliding, and your cover was blown. Ball first, they'd just squish between your toes and you just had to grit your teeth to stay quiet.