-

Posts

221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Will Brouwers

-

Atha 12lb cast steel sledge hammer problem

Will Brouwers replied to Will Brouwers's topic in Hand Hammers

These pictures that I took are pretty bad, but it isn’t really mushrooming. The big chip you see in the top left of the first picture goes into the hammer. It is more chipped than mushroomed. So maybe I should weld it like Frosty said? I guess I just assumed that welding an old hammer head like this is similar to welding an anvil, it’s not recommended. I wonder if I need to preheat, and if that would screw up whatever heat treatment there might be? -

I received this hammer recently and wasn’t too concerned about the head, but the more I looked at it, the more it looks like the head is mushrooming. The first picture shows some very sizeable (like 1/8) chips taken out of the sides of the head. In addition to this, the second picture shows that there are small cracks that I think, over time, will lead to similar problems. I don’t know whether to use a flap disk and grind until the cracks are gone, and try to blend the bigger chips, use it as is until something changes, or if it is just a wall hanger?

-

Ok, I have always wanted to keep small bearings, but the small amount of usable metal and the shininess has always kept me from keeping them.

-

David, What will you do with the bearings?

-

Same George. In my research I think it is for a print shop, that squeegees ink onto shirts and stuff. Apparently they need the angle of the plastic or wood or metal to be “sharpened.” I was going to ask the guy how fast it spins, and figure out if you could take metal off with it, but with the motor it has on it, it seems like it could get fast enough.

-

I’m not sure if it needs converting, that’s why I’m asking those who have more experience with belt grinders. It is a 1/2 hp motor with 1725 rpm

-

I’m looking at a squeegee sharpener on Facebook. If it does what I hope it will, I think it will be a good price, the only potential downside is the layout of the machine, everything being on its side. Thoughts?

-

A farmer let me take this from their scrap pile. It is the first bit of wrought iron that I will attempt to forge. I know to get it hot and keep it hot, but now I am trying to think of what to make! Nails?

-

Dang!!! 35 bucks!?!? What a steal! I have never seen a vise like that before, so whatever you do DONT SCRAP IT!!!! That is history right there!!!! I wonder if you slide a board(s) through the upside down L shaped bracket and that is how the vise is mounted?

-

What did I do wrong?

Will Brouwers replied to Will Brouwers's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Aha! Thank you! -

Well said Buzzkill. I would like both of them it in this working man's hands....

-

What did I do wrong?

Will Brouwers replied to Will Brouwers's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Thank you to all the replies! This was very, very helpful! I forgot to add that I tried to quench it the first time in motor oil (I know, not a recipe for success) but the edge kept deforming when I tried to mark things cold, so then I moved up to a water quench, and it still deformed. I am aware that leaf spring is not an ideal material, which is part of the reason why I decided to make this experiment and then learn from it, with the help of everyone here! I should have added that I do have a hot cut from Ken's Custom Iron that is not hardened, and when I would try to score material cold, it would deform. My intent with this tool was to use it as a cold cut hardy, while also getting rid of some of the leaf spring I have. I should have thought more about it and shaped it like a cold cut hardy, instead of so thin like a hot cut. I will definitely put all these comments and thoughts into use the next time I try something like this, and will most likely make the degree of the cutting edge more steep. -

I know! What is up with that? Definitely NOT an indicator of your work.

-

I hope this is in the right place, if it is not, Mods please have mercy. I am not trying to cause chaos with my posts. I forged this hot cut hardy out of leaf spring, and while using it today, the cutting edge started chipping and then suddenly the shank and the rest of it cracked. Attached are pictures of the grain. I don't know if that was the problem, or if there could have been microfractures, or if the way that I got it to fit in the hardy hole (heating it up and hitting it hard) is what led to it's demise. It was also interesting, the top kept deforming, even though I had quenched it in water, and then it cracked. It seemed like it was too soft, and then too hard. I am only a beginner, especially when it comes to heat treating.

-

Is this Really a Kohlswa???

Will Brouwers replied to Joel K's topic in Anvils, Swage Blocks, and Mandrels

Wow! Thank you for all of these examples! -

Beautiful. Wow. Something to work towards. I love the grandson and grandfather thing too! Very fitting!

-

Is this Really a Kohlswa???

Will Brouwers replied to Joel K's topic in Anvils, Swage Blocks, and Mandrels

Technicus, could you give some examples of the new features on anvils that are not well considered? -

HELP? What is this anvil?

Will Brouwers replied to BoardMoreThanUsual's topic in Repairing and Modification to Anvils

It is interesting that there are no other distinguishing marks or words helping us know for sure if it is a Vulcan from England. Normally they have the word WORKS next to the word Vulcan. I'm trying to do some sleuthing googling Vulcan anvil England and looking at the results in images. -

HELP? What is this anvil?

Will Brouwers replied to BoardMoreThanUsual's topic in Repairing and Modification to Anvils

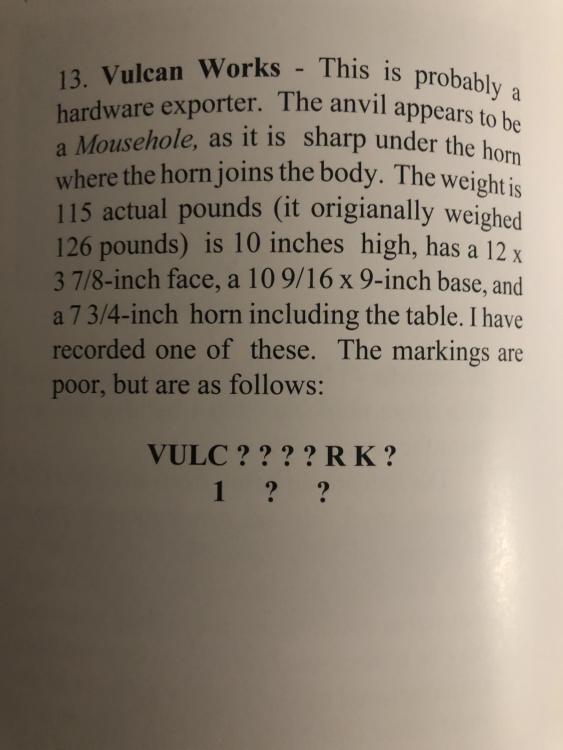

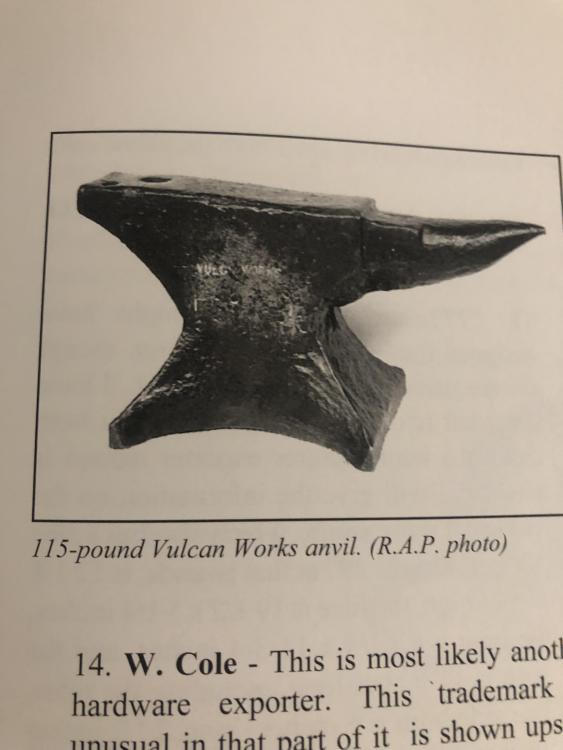

That's a good looking anvil! In my opinion, it looks like lettering VL?CAN. When I look up Anvils in America, I see under the English Anvils section a little blurb on Vulcan Works. Attached is a picture of the section. Also, Board, did you know that those square holes were used to make the anvil? While it was hot, the makers would put long square bars in them to better be able to maneuver the hot and heavy anvil under the power hammer. -

Sheesh! What was the starting stock?

-

You could try vinegar or continue letting nature do its work.

-

Pretty cool! Leg vises are so useful, for more than just blacksmithing. Any idea how and to what you will mount it?

-

George, I used to exchange my tanks at the local Walgreens, but I was going to go to U-Haul and have it refilled instead of exchanged. Is that what you were talking about? Getting my tank refilled is better than exchanged?

-

If you are quoting the “Beautiful Boy” song, that is an amazing song!

.thumb.jpg.0d8ded55adb89e038cc2e2d5af905291.jpg)

.thumb.jpg.8f22d54d80c8ae4226cea00e04792cb1.jpg)