-

Posts

221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Will Brouwers

-

Well, results of today. I forged for 2 hours, and made lots of mistakes. The final mistake was to gently dip it in water a couple times to cool it so I could see how I liked it in my hand. Then it cracked. Chucking it in the water bucket didn’t help either, but now I am thinking, can this be salvaged? It would sure be a thin profile though…

-

Thank you George! I have tried to see if this will harden, and it does. It shatters when hit after being hardened in water, and is much tougher after being hardened in oil.

-

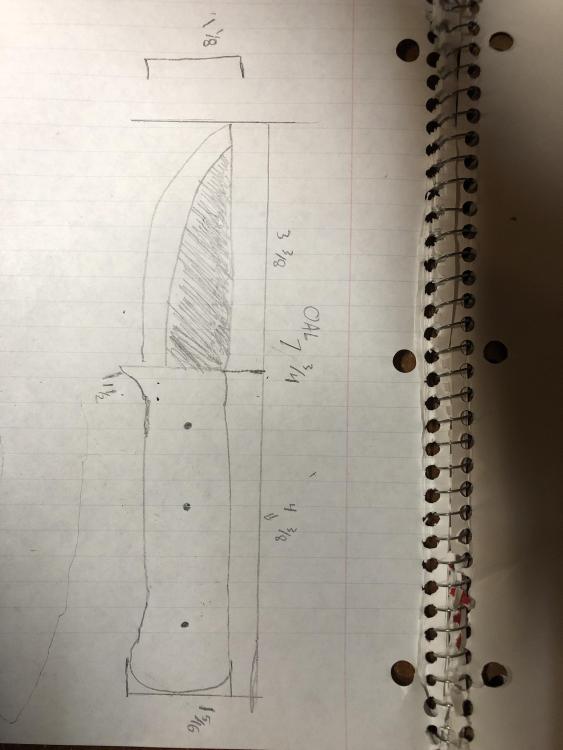

This might be too ambitious for a beginner blacksmith like me, but I have this knife drawn up, with the hopes of forging it out of 1/4 leaf spring, 1 1/2 inches wide. The question is: do you think this will be enough material for what I am aiming for. My overall length would hopefully be around 7 3/4 inches.

-

Ideas for a Broken Pancake Air Compressor

Will Brouwers replied to Will Brouwers's topic in Everything Else

That's a great idea! We'll see if I get around to it, but thank you for getting my thoughts going! I also thought about using it as a dishing block? I'm not sure how well it would hold up though. -

I found this in the dumpster today. Normally I would scrap this kind of stuff, but before I did I wanted to see if it would be work keeping for something else.

-

I was on Youtube the other day and saw this video in my suggestions, after ignoring it for a while, I decided to watch it and was pleasantly surprised. The creator makes charcoal in a cone shaped bowl, which allows the wood to burn, but as more wood is added, the burnt wood underneath does not receive air and is turned into charcoal. I thought it was an interesting way of making charcoal and one I had never heard of before. I also think this video and many of his other videos are worth watching because he has the same heart/mindset of many of us here, CREATE! He has a small, working railway in his backyard that he uses to make life easier. He has a (sketchy) woodchipper run off a steam engine, and some other equipment run off the engine as well. Pretty interesting fellow!

-

Thank you for the quick responses! I will definitely take what you said into account. My charcoal was mostly small enough, but there were definitely some pieces that were too big. I am using a hand crank blower, and would once in a while give it a good blast to clear the ash out. I varied in how fast I went.

-

I hope I am not a repeat of every other question about side blast forges, but I spent about an hour trying to heat and taper a 1/2 inch piece of steel, and trying to find the sweet spot in my forge was incredibly difficult! I have forged with a mentor in his bottom blast coal forge, but I used a half a bucket (5 gal.) of charcoal and only got some pretty rough tapers to show for it. Is this normal or is there something wrong with what I am doing? I did what was suggested and tried to raise my tuyere an inch above the forge floor, but I think it ended up being a half inch. The best heats I got were when the steel was about an inch above the tuyere. I tried a little experimentation, but nothing else seemed to work. Also something I noted was that the charcoal around the steel was up to temperature, but the steel wasn’t. Thanks for reading through my long winded thoughts!

-

Hello, just wondering if you guys had any experience or pictures on using copper on your ironwork. I have done some research trying to find other threads or posts, but have found none. I have thought about doing some wire wrapping on a split cross, specifically around the hole in the center, but have also thought about splitting a split cross' arms and making a dragonfly out of it, and then maybe adding copper wire as legs. Before I start messing around with all of that, I was hoping for some clarification. Also, does beeswax work as a good finish on copper? Thanks, Will

-

Show Me Your Antique Drill Press

Will Brouwers replied to Brenton's topic in Drills, Post drills, Mag drills, etc

That would be about $80-$90 today (which is crazy.) Would you say that what you got yours for was a good deal? -

Show Me Your Antique Drill Press

Will Brouwers replied to Brenton's topic in Drills, Post drills, Mag drills, etc

What is a good price for one of these. I have found a couple, but have no idea where to begin. -

Just your every day, run of the mill 9-5 job....

-

What did blacksmiths make in the 1800's

Will Brouwers replied to Will Brouwers's topic in Historical Ironwork

Thanks again for all the replies. I am mainly interested in the Great Lakes Region, but just learning what blacksmiths made is a great place to start, so thank you for those suggestions! -

What did blacksmiths make in the 1800's

Will Brouwers replied to Will Brouwers's topic in Historical Ironwork

Thomas, I appreciate you honing my area of interest. I know I have posted similar questions in other threads, and I apologize for my obsession. I am interested in what a blacksmith would have done in both the East and the West, mostly in the Northeast and Northwest, as well as Midwest. I think I am still trying to figure out how to represent, as accurately as possible, a specific time period and place. -

What did blacksmiths make in the 1800's

Will Brouwers replied to Will Brouwers's topic in Historical Ironwork

Thanks for that link Irondragon, it was very helpful! Thomas, I am only concerned with the U.S. mostly between 1800-1850. -

I figured this forum would be a good place to pick your brains. I have done some research elsewhere online, but it amounts to "they made horseshoes." This question is mostly just some research for fun, but I also would like to focus on this time period when I forge. I also realize that the 19th century is a wide range of time. I also realize that the responsibilities of a blacksmith in an east coast city would be different than out west. I just wonder if blacksmiths out west were still making things nails in the 18th century. Any thoughts are appreciated, and any sources are doubly appreciated! Will

-

Thanks Pedro, I looked at the end and there was a cut mark. It is weird though, the wooden handle has OTTO stamped into the side of it.

-

Got this box at a garage sale Saturday. I was told that it might be made around the late 1800’s to early 1900’s. Some great tools, and some confusing ones. Any ideas? The one tool looks like it might be a rasp, but with a handle? The other one looks like an early version of channel locks lol.

-

Quenching in new motor oil?

Will Brouwers replied to Will Brouwers's topic in Heat Treating, general discussion

I really appreciate the concern, both for my health and for the consistency of my forging. Before this, all I had was water, partly because if I was going to spend money on quench, it was going to be the good stuff. I am aware of how bad motor oil is to use, but for the price and the ability to practice, it worked just fine! -

I think this is the right place to put this, although it is more a celebration of new possibilities than anything. One of my neighbors gave me 4 quarts of new 0w-40 motor oil and I spent the last hour testing out pieces of scrap that I had that I thought might be high carbon. With this oil and the capabilities it gave me, I finished making my first tool, a hot cut chisel!! I’m pretty excited, because now I feel like a “real” blacksmith! I should also add that I have actual quench oil on my list of things to buy, this motor oil just came to me and I decided to see what I could do with it!

-

What did you do in the shop today?

Will Brouwers replied to Mark Ling's topic in Blacksmithing, General Discussion

That is true. This one was mostly just to see if I could. Because she is my wife, I didn’t want to push my luck today! -

What did you do in the shop today?

Will Brouwers replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frosty! I felt pretty good about all of it, none of it is the best, I might hit a few pieces with the wire wheel, but my main win today was that I felt GOOD. As I swung the hammer I felt like I could hit powerfully and accurately, I experimented and it worked and I didn’t overthink. I wasn’t even that tired, even though I started my summer job of working concrete this past week. It was an easy week though, only 2 ten hour days, one 12 hour day, and Friday off! However, after asking my wife what she would pay for the candle snuffer, she said if it was really good, she’d pay $5. You can’t please them all. -

What did you do in the shop today?

Will Brouwers replied to Mark Ling's topic in Blacksmithing, General Discussion

3 hours of work. Pieces for a boot scraper, my first drive hook and candle snuffer, each from a split cross cutoff and then a garden shovel blank from black pipe, inspired by Jvos Ironworks on Instagram. -

Building a new smithy and workshop in Uk

Will Brouwers replied to RogerrogerD's topic in Building, Designing a Shop

Roger, I just looked through this whole thread and I absolutely love your shop! Especially those pictures of it at night! What a cozy place to be! I took a few screenshots to add to the list of ideas that will hopefully culminate in a shop of my own! Until then, it is the basement and the backyard for me!