-

Posts

221 -

Joined

-

Last visited

Profile Information

-

Location

Cawker City, KS U.S.A.

Recent Profile Visitors

1,263 profile views

-

Next steps for my first axe

Will Brouwers replied to Will Brouwers's topic in Axes, Hatchets, Hawks, Choppers, etc

Thanks for sharing that David!! -

Ideas Needed for a Grinder Build

Will Brouwers replied to Will Brouwers's topic in Grinders, Sanders, etc

Yes! I forgot to mention that. I am thinking of using a piece of angle iron and bolting it to the arm sticking off the side of the big piece of angle in the first picture, that way I can tilt or remove it if I need. -

Next steps for my first axe

Will Brouwers replied to Will Brouwers's topic in Axes, Hatchets, Hawks, Choppers, etc

I have considered getting a set of their drifts! think my plan is to use some big round drifts that I have and just make the eye like a hammer eye. So I will still be able to thin the cheeks of the axe out. -

Next steps for my first axe

Will Brouwers replied to Will Brouwers's topic in Axes, Hatchets, Hawks, Choppers, etc

David, Thanks for responding! When I was writing this I was thinking about your axes and hatchets and hoping I would get your wisdom and expertise! I am putting the cart before the horse with this project. I was (naively) hoping that I wouldn’t need a drift, or that I could get by without one. I do have a marlin spike that I use as a drift and a smaller round drift. I was also trying to forge out an axe drift, so I will continue doing that. Thanks for the help! -

Ideas Needed for a Grinder Build

Will Brouwers replied to Will Brouwers's topic in Grinders, Sanders, etc

Just an update on how this grinder turned out. It is great! I had a friend who suggested the idea that led me to this idea! Just weld legs to the bottom! It kind of gives me Eiffel Tower vibes, and I really like it, and it works great! Definitely a great addition to the shop! The belt doesn’t track the greatest, but it works well enough, good enough for me to work around. In the second picture you can see the belt goes over a piece of angle iron that allows me to have something to push against. The next step is to weld another piece to that angle iron piece so all of the belt can be used, and to weld that screen below the grinder to the underside as a shelf. -

Hello all, a friend and I are making a pair of axes. This is my first time trying to do this, and I don’t know how to proceed. The eyes are too long, so I was going to try and upset them to make them more round, and then put a drift through them to make them the right size, but the cheeks are very thick. Should I try to thin out the cheeks? And should I do this with a cross pein or fuller, or just the flat hammer face? Also, the transition from the cheeks to the blade of the axe seems too thick to me, but I wonder if thinning out the cheeks would help with that?

-

Thanks for educating me on the use of mouse holes Frosty! Any chance you remember where you learned that information?

-

tcb, with only 2 pictures it is hard to tell what you have there. Some places to look for answers would be at the waist, the narrowest part of the anvil, for any lines of weld where they may have arc welded two pieces, or even harder to tell, where they may have forge welded. The next part is about 3/8-1/2 down from the face of the anvil. Many anvils have a high carbon steel face welded to the top, if it doesn’t have a line where it looks like two pieces of iron meet, odds are it is cast. When wire wheeling, look on the sides of the anvil for markings, or look on the front foot. I’m not sure how different U.S. and UK anvils are, but that is where I look on each anvil. I’m sorry to see all that pitting. Is the whole face like that? Before you go trying to fix that, maybe see if you can use other parts of the anvil. It is easy to remove metal from an anvil, not so easy to replace it properly. Edit: This is a forged anvil, because of the square hole (mousehole) in the front. The makers of anvils would stick a big bar in there to help them manipulate the heavy chunk of metal they were forging into an anvil.

-

What did you do in the shop today?

Will Brouwers replied to Mark Ling's topic in Blacksmithing, General Discussion

I might steal both the leaf J hook and John’s quick and easy tongs! That stuff looks great! -

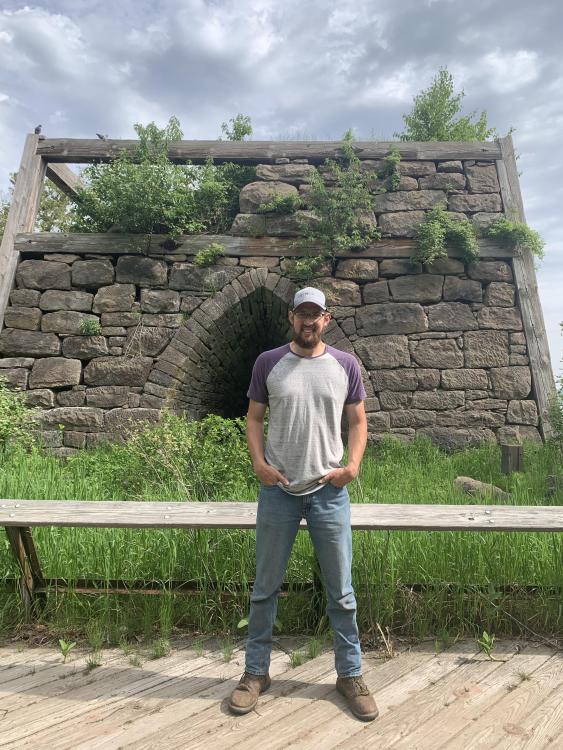

This thread started right as my wife and I put a cabinet in our kitchen, that I promptly put my artifacts (read knickknacks) in! The first artifact is a Native American axe head that my grandpa found while he was plowing at his farm in northern Indiana. I am very proud to have it! I have always wondered if the straight lines across it are from the discs of the plow. The next three are really cool. They are byproducts of the smelting process of the Bay Furnace in Munising. I found the green, glassy thing when I was in high school when my family went on a vacation there. I thought it was cool, and some kind of green obsidian. Then, years later, I was bit by the blacksmithing bug and in reading about metallurgy and blacksmithing, I saw something about slag being a “glassy byproduct of smelting, sometimes green, etc…” I thought to myself “I have something green and glassy!” Turns out it is slag from the Bay Furnace. Later, my family and I now with a wife in tow, went back and I combed the beach and found a TON of other byproduct. The first picture is a mass of slag and iron and charcoal, just showing all the different ingredients in making iron, and the next picture are two iron clumps, magnets stick to them and they have the rust color. There is a part of me that wants to try and refine and forge them, but I like how they are now. The second to last picture is of more slag that I found. The last picture is of me in front of the furnace. There was one more level on top, but that has fallen away through the years. It is pretty cool there, right on the shore of Lake Superior, you can camp there too. I do feel a little guilty for taking the stuff, especially since the beach was eroding pretty bad, but I don’t think many other people would see anything special in the stuff I took… I also thought about things like ground contamination after the heavy industry that was there.

-

Wow! That is really, really cool looking! My brain gears are turning now!

-

No. I was 9 when we moved, so the blacksmithing bug hadn't bit me yet.

-

I want one of these shears if only because they were made, or branded, Albert Lea, MN. I lived in the small farming town of Hollandale, 15 minutes away from Albert Lea.

-

That 10 is HUGE! How much does it weigh????