-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ross Moffett

-

Press Design - To have or not to have 45 degree joins?

Ross Moffett replied to Ross Moffett's topic in Presses

Jspool: Thanks for the reply. Sometimes -read mostly always- I may get a bit carried away with trying to get a "neat" design, your advice is definitely a better and more economical route, especially if I can't get hold of a metal bandsaw to use. Though I think I shall still put gussets in all the corners. Ross -

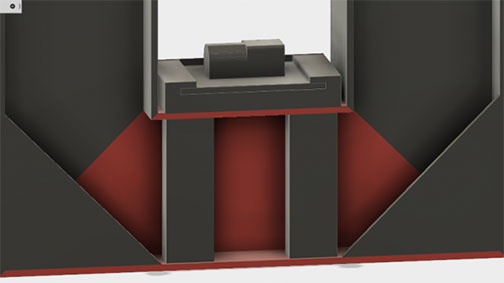

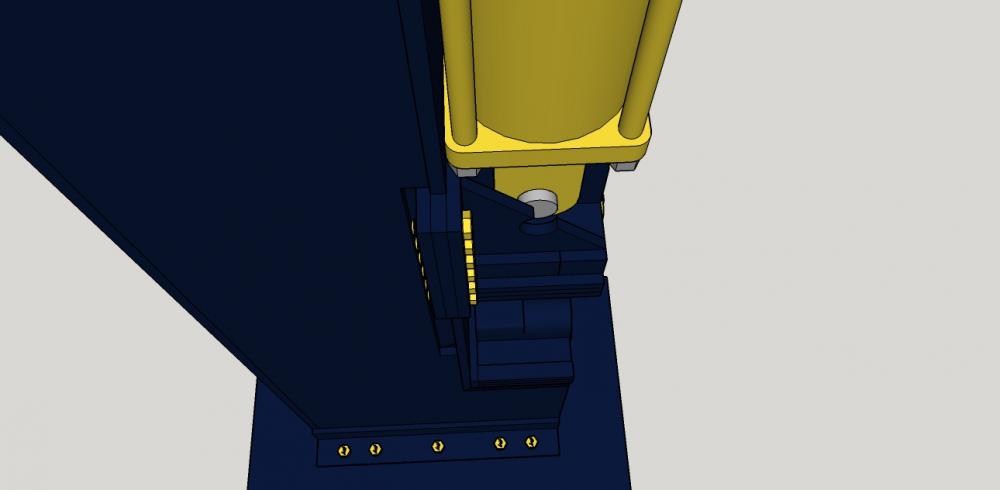

Hi Y'all, My latest press design has the I beams connecting at a 45-degree angle, my question is if this is as structurally sound as say the beams connecting at 90-degrees? I've colored the I beams different colors for ease of viewing - refer to image below. Thanks in advance, Ross

-

Good luck. The log splitter method WILL be the easiest, safest and cheapest. Give me a shout if you need help with anything! turning log splitter into a press is not easy or always safe

-

michael klemz, I wouldn't go any lower than 16 tons, I suggest you check out Coal Iron Work's presses to get a general idea of pricing... IF buying a press is out of the question then maybe look into getting an old log splitter (20 + tons) and convert it into a forging press, which would probably be cheaper and easier than building a forging press from scratch. Check out Big Dog Forge's video about converting a log splitter into a forging press on youtube. Make sure when buying a log splitter that the quoted tonnage is not quoted from the log splitter's ram cutting edge and rather the cylinder's rod because of smaller surface area = more tonnage (I hope I've made at least an ounce of sense.) I'm sure more experienced people will chime in soon and give you better advice than mine. Disclaimer: I'm only 15 yrs so don't take anything I say for granted!! Ross

-

ianinsa, Thank you for the offer but unfortunately, I'm moving down to the western cape (Overberg area) later this week. Although I would greatly appreciate it if you could maybe send the presses and power packs specs? Thanks and regards, Ross

-

Received a reply from the seller, he says he thinks it was used as a molding press, so probably won't work for forging.......? Regards.

-

Hi Y'all, Found this hydraulic press on "Gumtree" and I was curious if it could be used or adapted for forging? The description given by the seller: Good condition. Heavy duty. 300mm opening. Good value. Was going for 40000 then 30000 and now it's 20000, price in South African Rand. Thanks in advance.

-

All the log splitter presses I've seen have been converted to electric, remember electric motors are stronger than gas.

-

BeaverNZ - Good advice will do.

-

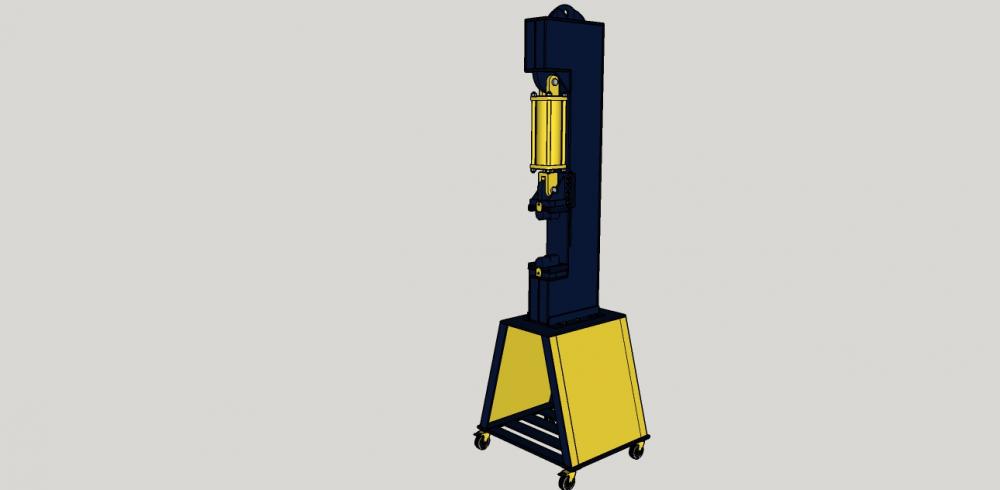

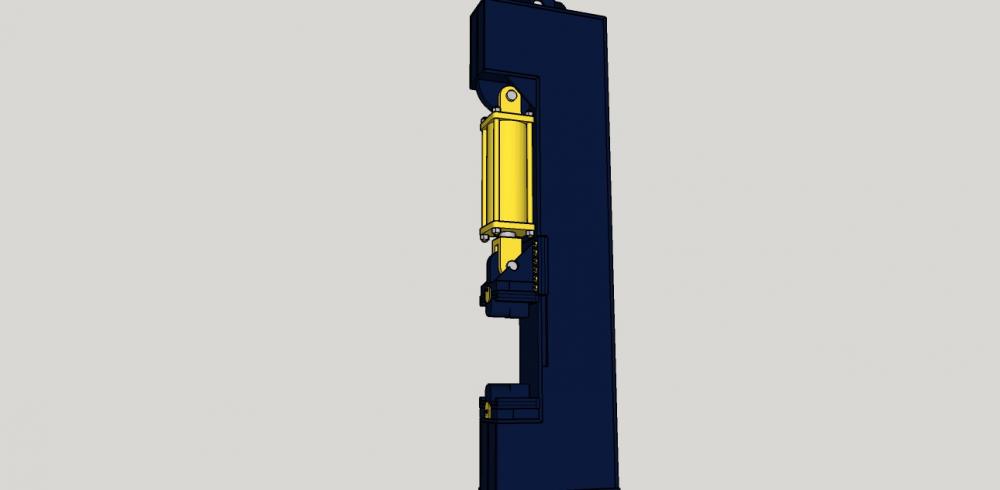

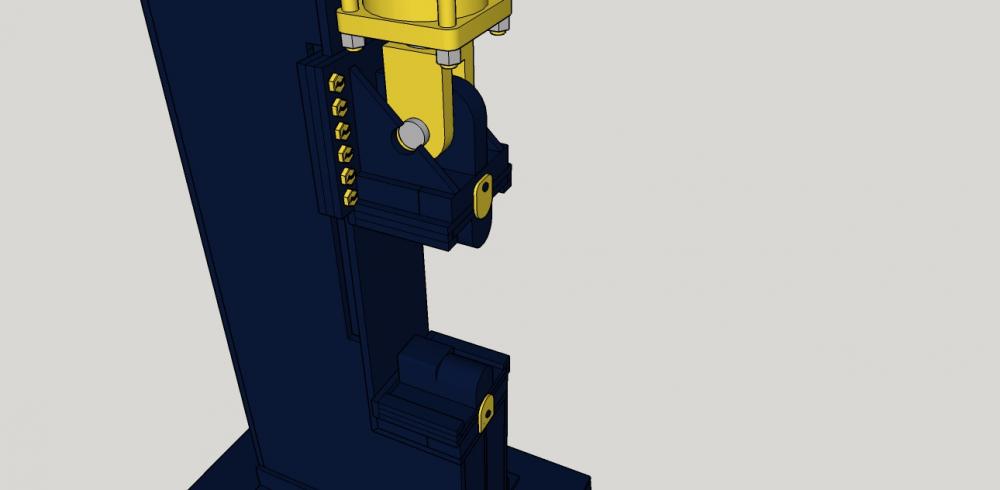

Hi Y'all, So I've been doing loads of research and designing and I've finally come to the stage where I can start ordering the parts for the press. Anyways here's my reason for posting, my calculations and the page about the pump say for a 10.51 GPM, 3000 psi, 2 stage pump I need a 7 hp motor. BUT Coal Iron Works 25 ton press uses only a 5 hp motor for a 13 GPM pump and McNabb's 24-ton press uses a 3 hp (not sure what pump though)!?! Am I doing my calculations wrong or something? I'm going to be using a 5 X 8-inch tie rod cylinder. Thanks in advance! Here's a quick "animation" of the press. The press is just over 7.5 feet and working height is around 3.5 feet. "Edit" added some images in case the "animation" doesn't work. Recording #4.mp4

-

I'm no expert but I'm sure some forge gurus will chime in soon. Welcome aboard!

-

Coffin handle Sheffield Bowie in damascus with hamon

Ross Moffett replied to TheoRockNazz's topic in Knife Making

Beautiful piece, though I can't say that handle looks too comfortable. Correct me if I'm wrong!?!? Of course, it would have been a lot harder to do the inlay if it wasn't flat. -

I really need to try this! Thanks for the tip Beaver.

-

Very nice work, clean and simple.

-

Welcome aboard Mark!

-

Very VERY nice work.

-

Astounding work!

-

What did you do in the shop today?

Ross Moffett replied to Mark Ling's topic in Blacksmithing, General Discussion

Foundryman - That pattern is spectacular, yet very clean and simple. -

Welcome aboard Baz! It's always nice to see the blacksmithing bug bite again. All the best, Ross.

-

Neat video....some different techniques

Ross Moffett replied to MilwaukeeJon's topic in Knife Making

Of course... I've heard wetting the anvil and hammer helps blast scale off the workpiece, though I may be totally wrong?!? -

Neat video....some different techniques

Ross Moffett replied to MilwaukeeJon's topic in Knife Making

Don't worry @Steve Sells you weren't the only one who winced (to put it mildly) at the "blood groove" comment. -

Neat video....some different techniques

Ross Moffett replied to MilwaukeeJon's topic in Knife Making

Maybe and maybe also to remove scale? -

Frosty, hope you get better soon.

-

Welcome aboard Craig!

-

Thank you, I really appreciate all the replies. Good luck with the press and have fun making it! Let me know if I can help with anything. Regards.